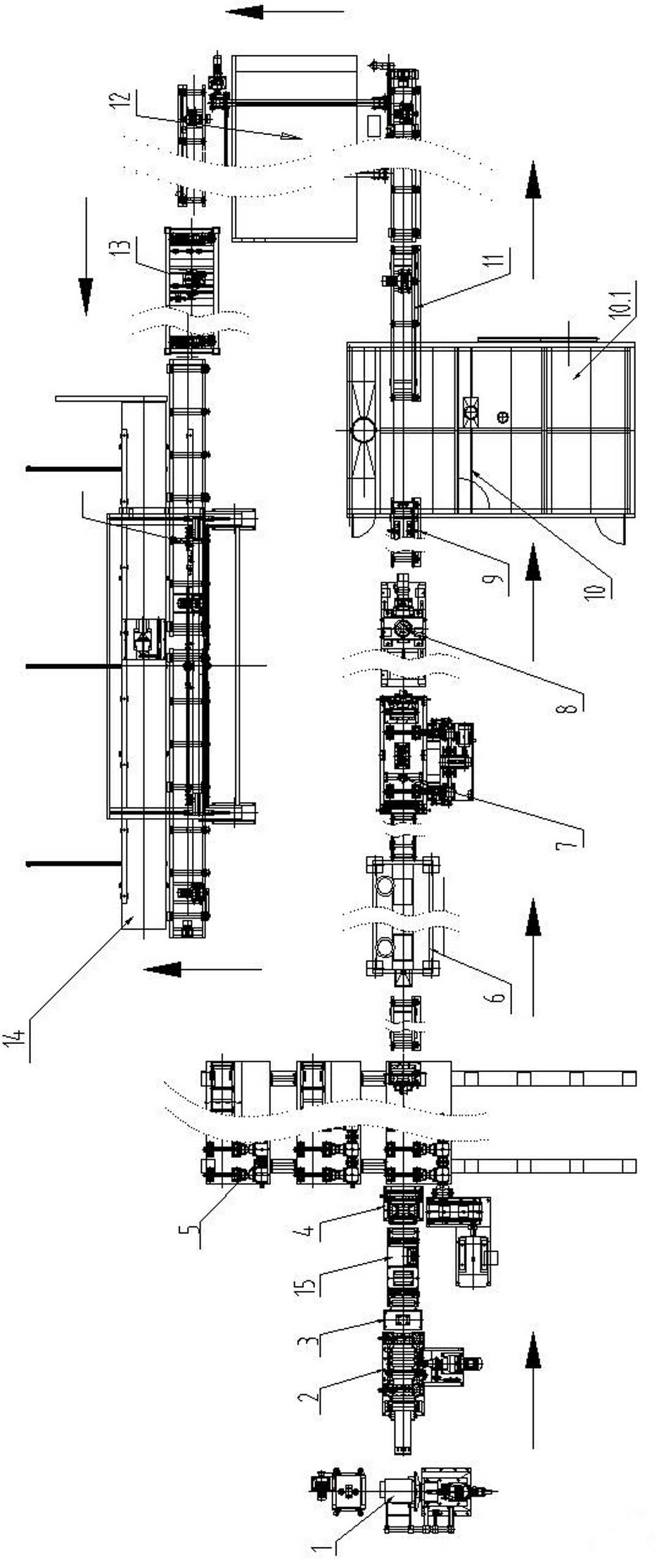

Automatic production line for full-continuous container section bar

A technology for automated production lines and containers, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of scattered production equipment, time-consuming and laborious, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

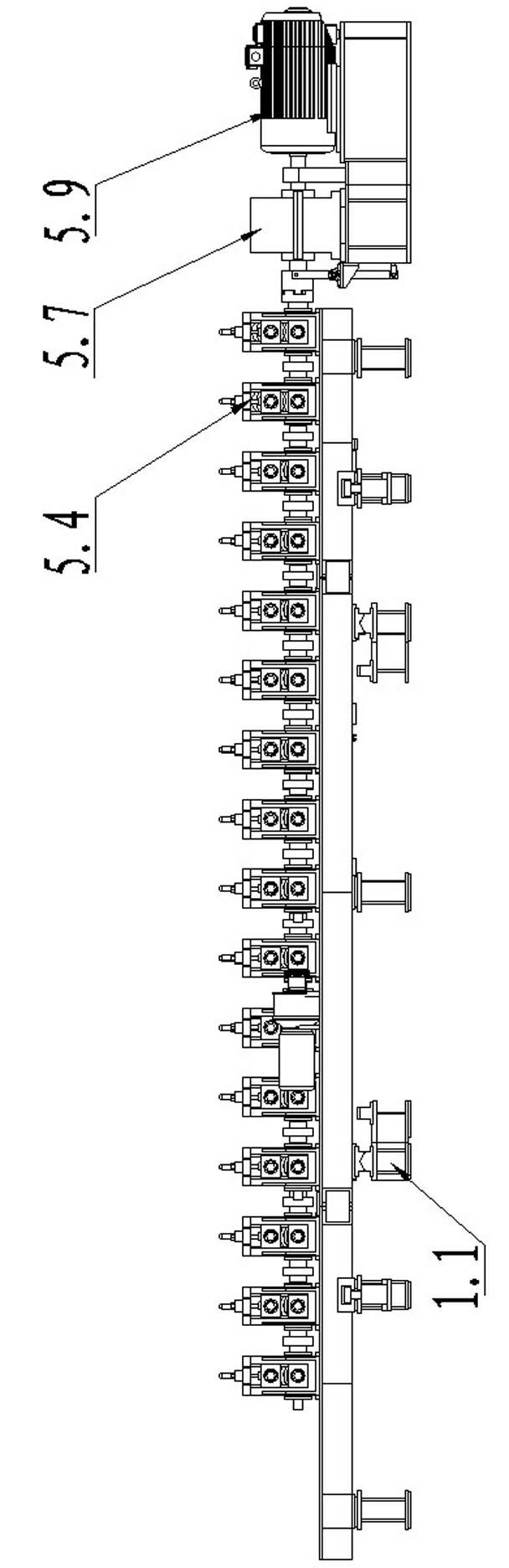

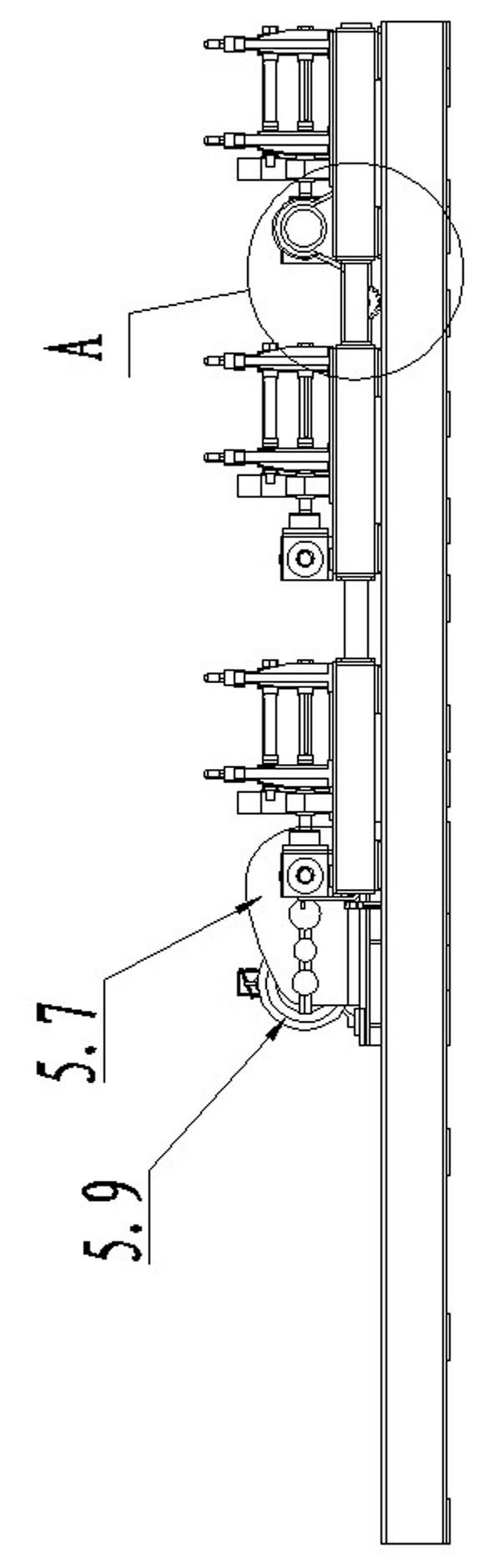

[0027] Embodiment: 1. Cold-rolled forming part: the steel coil is installed on the material coiler 1 by a crane, and the appropriate cold-rolled coil is selected through the positive and negative rotation of the motor I5.5 according to the shape of the cross-section of the container profile to be rolled. Forming mould; driven by the deceleration motor, the coil machine slowly rotates, and the beginning of the steel coil is input into the leveling machine 2 to level the steel coil thin plate. With the continuous rotation of the coil machine 1, the plate The material is slowly conveyed forward. Because the shape of the head of the new steel coil is different, it is not smooth enough. When passing through the head and tail shearer 3, press the start button of the head and tail shearer 3 to cut the head of the steel coil flat. ; Just can be transported in the cold rolling forming machine 5 under the guide action of vertical guide roller 4; Start cold rolling motor Ⅱ 5.9, now cold r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com