Automatic assembling machine for inserted type fuse and automatic assembling method for inserted type fuse

A fuse and plug-in technology, applied in the field of plug-in fuse automatic assembly machines, can solve the problems of high assembly labor intensity, unstable assembly quality, rising production costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

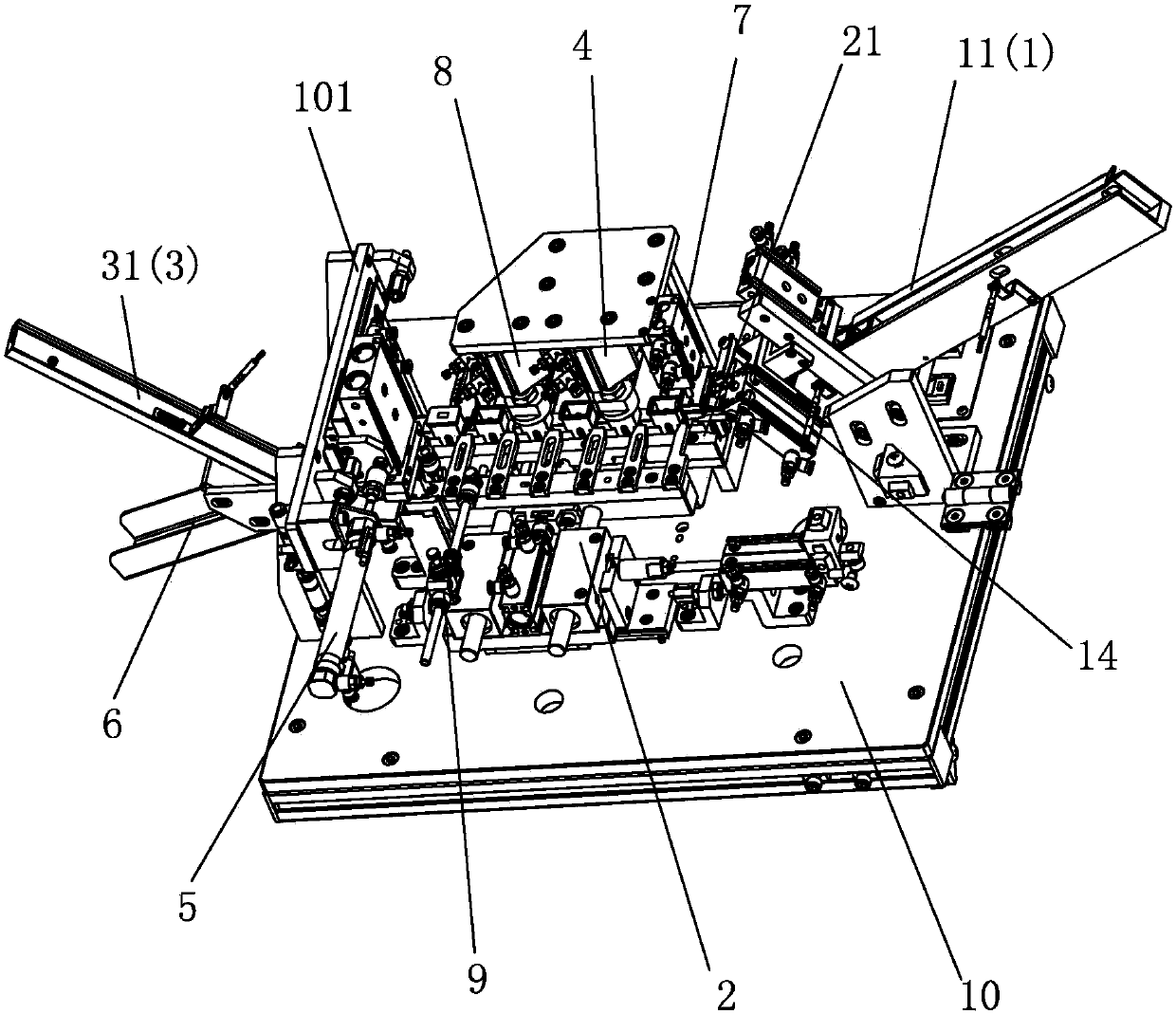

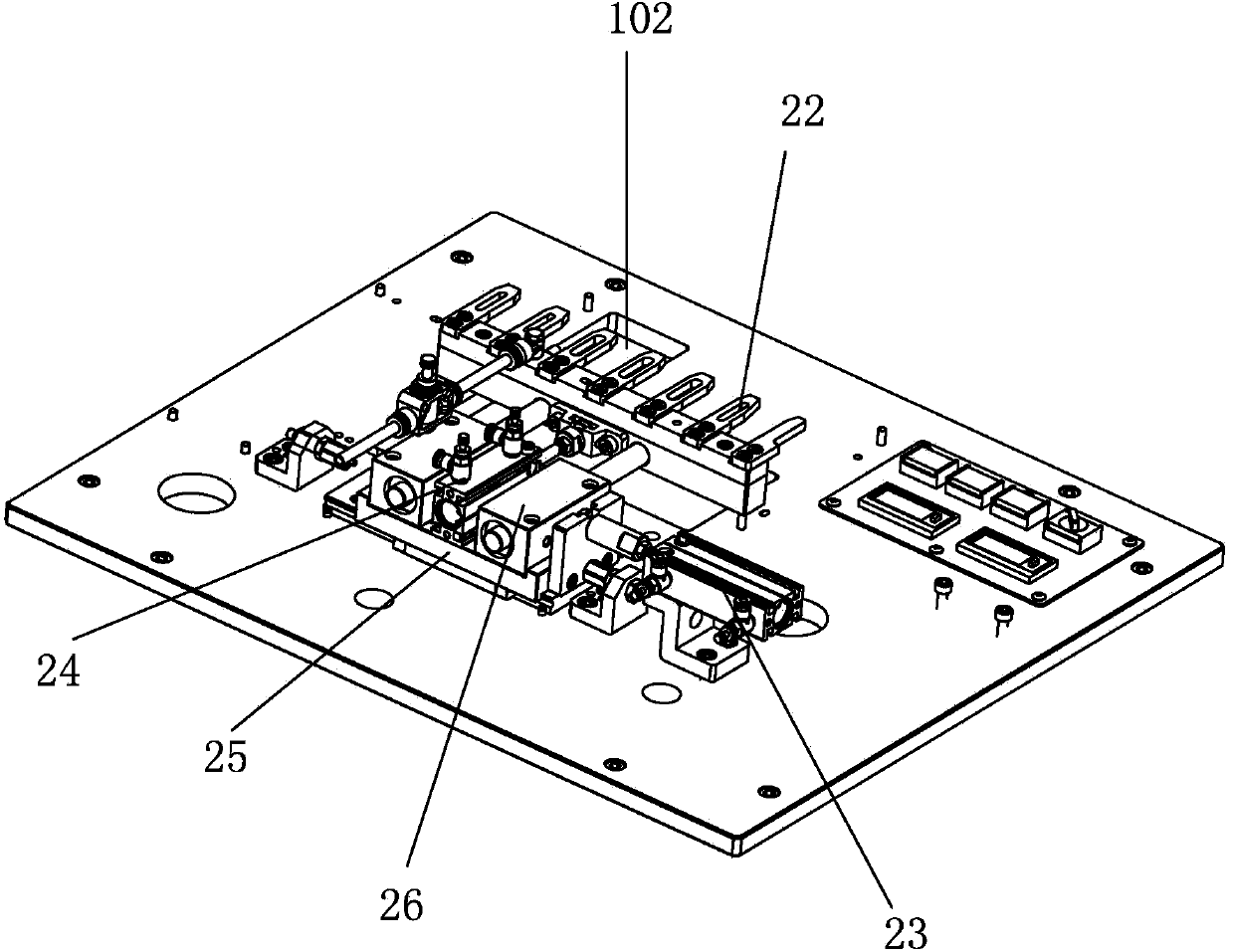

[0036] Please check Figure 1 to Figure 5 , plug-in fuse automatic assembly machine, the plug-in fuse includes shell parts, metal parts and upper cover, the assembly machine includes a machine base 10, and the machine base 10 is equipped with a seat for conveying the assembled shell parts and metal parts The first feeding device 1 of the subpart 20; the conveying device 2 for conveying the seat part 20 to complete each process in sequence; the second feeding device 3 for conveying the upper cover; the connecting plug for expanding the seat part 20 The hole reaming device 4 of the hole; The capping device 5 for covering the cover 30 of the seat part and the discharging device 6 for outputting the finished product;

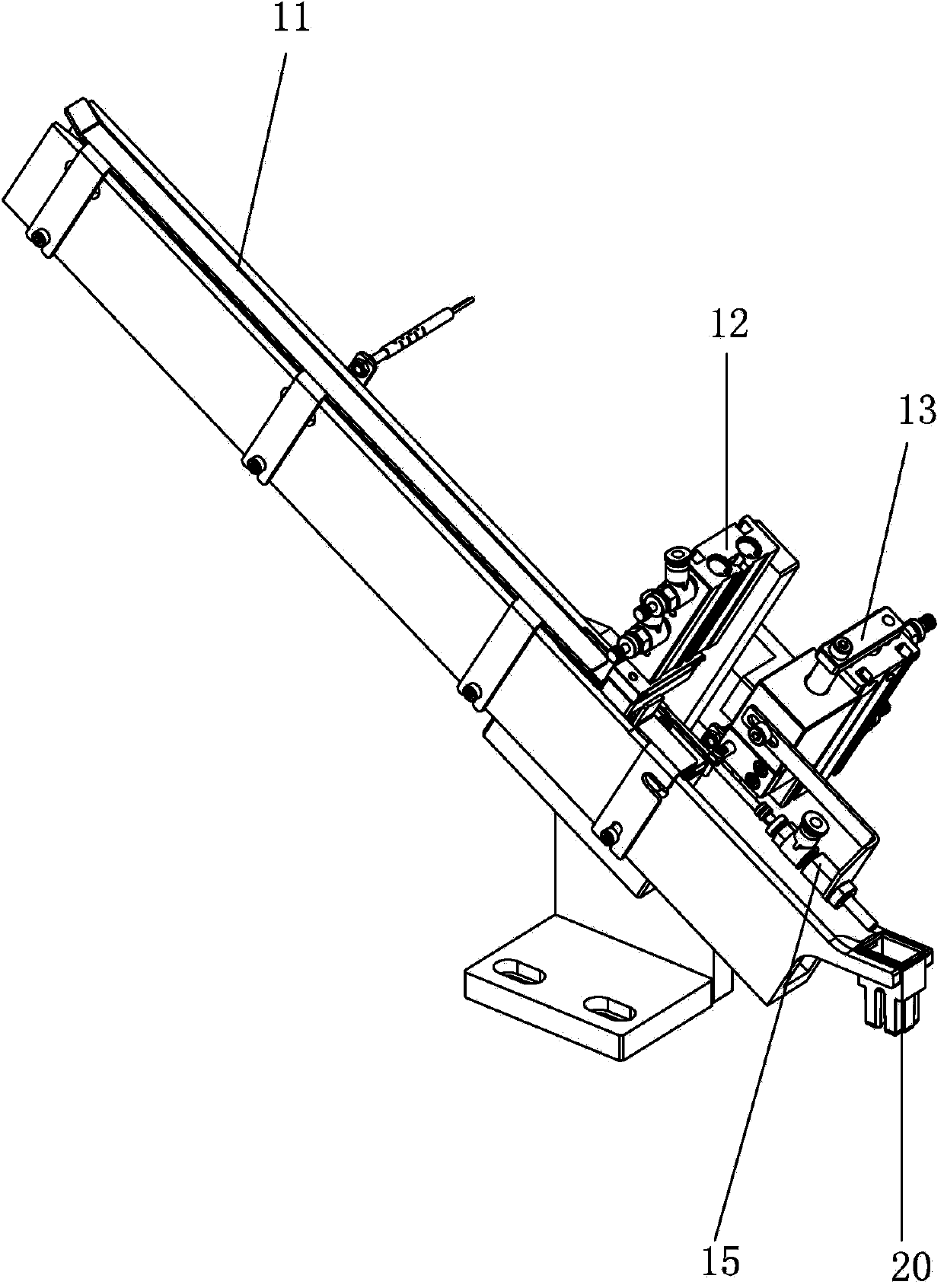

[0037]The first feeding device 1 includes a first feeding channel 11, the front end of the first feeding channel 11 is connected to the tail end of the conveying device 2; The second seat part on the feeding channel 1 is used to temporarily prevent the second desce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com