Forming method for solid electrolyte ceramic tube of sodium-sulfur cell

A solid electrolyte and sodium-sulfur battery technology, which is applied to ceramic molding machines, supply devices, unloading devices, etc., can solve the problems of difficult automatic operation and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] see Figure 1 to Figure 5 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

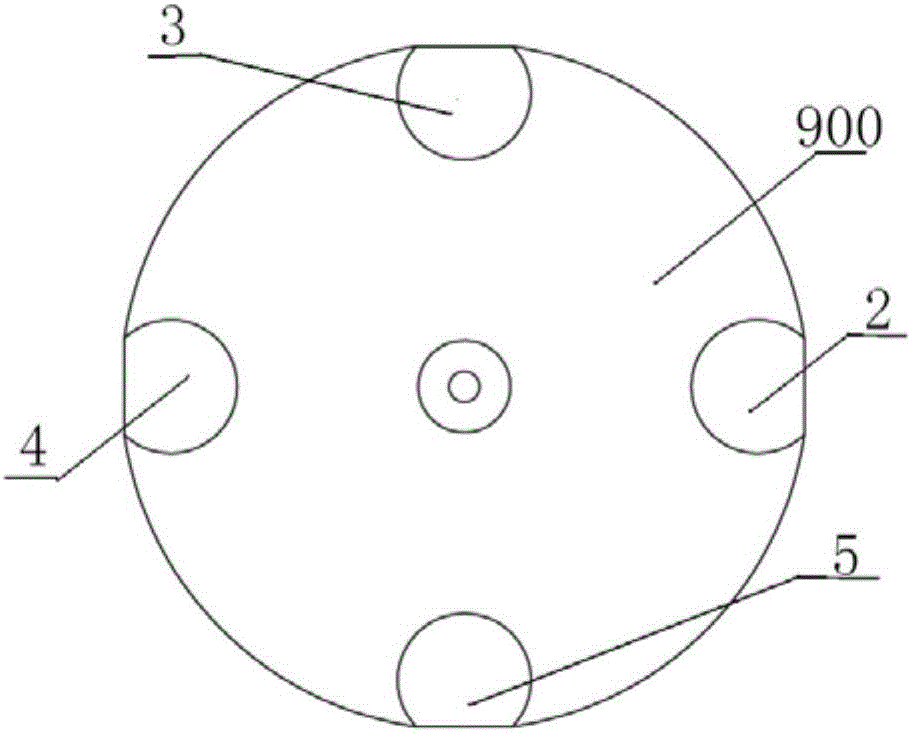

[0027] see figure 1 , Sodium-sulfur battery solid electrolyte ceramic tube molding device, including a horizontal turntable 900, the top surface of the turntable 900 is evenly distributed with four stations, followed by feeding station 2, pressing station 3, demoulding station 4 and waiting station 5. Each of the stations is provided with a forming mold 1 for forming solid electrolyte ceramic tubes for sodium-sulfur batteries.

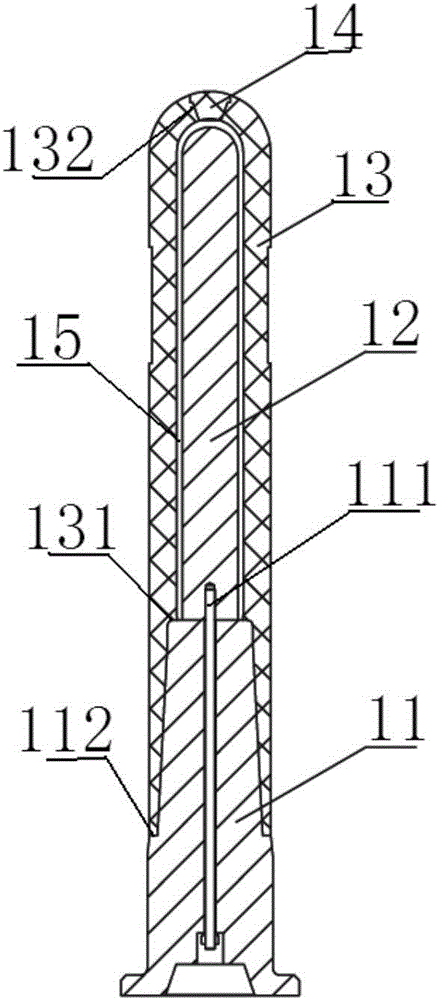

[0028] figure 2 The forming mold 1 includes a base 11 , a mandrel 12 , a rubber hose 13 and a rubber hose plug 14 . The bottom surface of the base 11 is fixed to the top surface of the turntable 900 . The mandrel 12 is coaxially fixed on the top surface of the base 11 , and the mandrel 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com