3D printer continuous printing system with automatic discharging and replacing functions

A 3D printer and automatic unloading technology, applied in the field of 3D printing, can solve the problems of low degree of automation and lower printer usage efficiency, and achieve the effect of improving enterprise efficiency, increasing individual production capacity, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

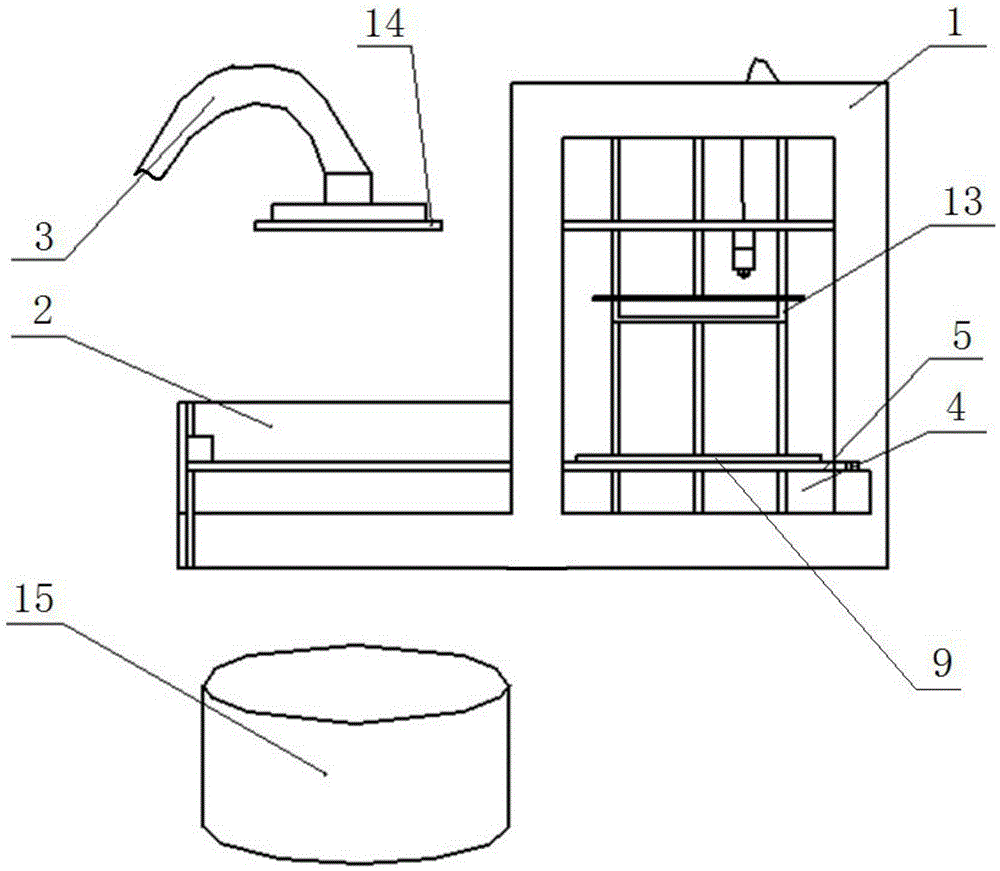

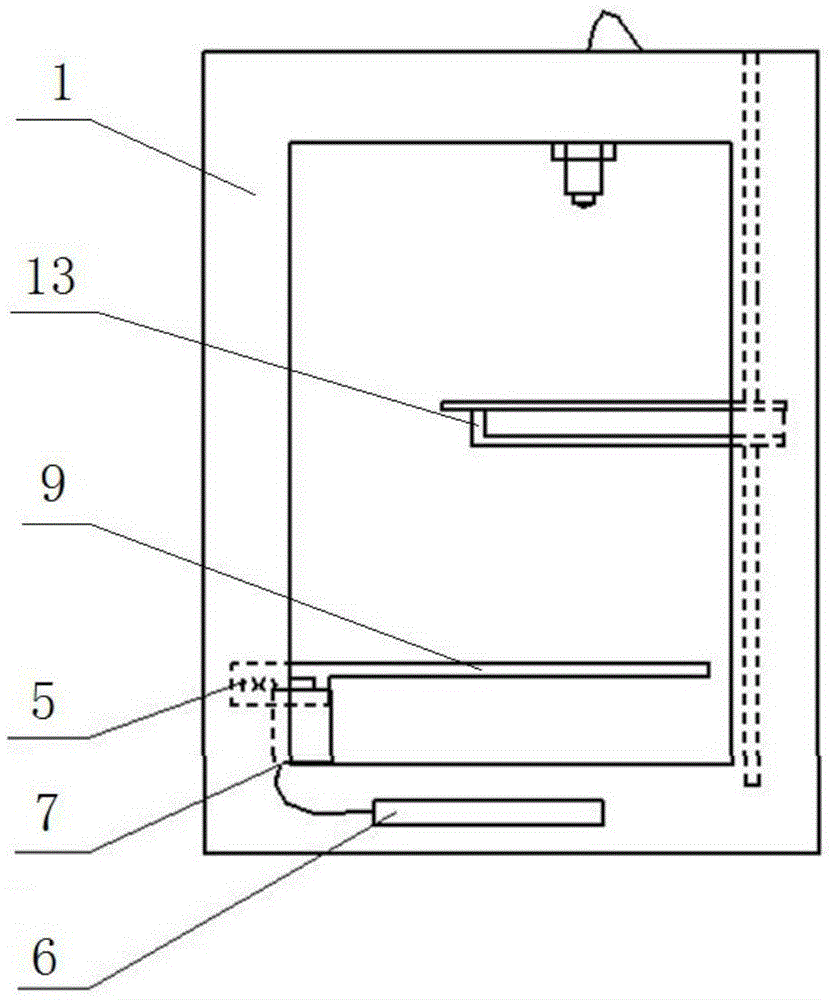

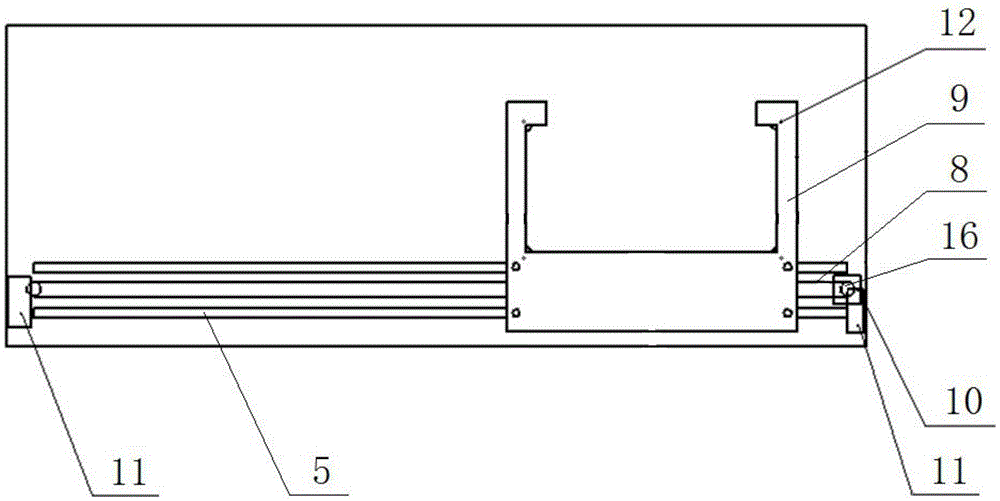

[0020] see Figure 1-5 , a continuous printing system for a 3D printer that automatically unloads and refuels, comprising a printer 1, a refueling platform 2 disposed on the left side of the printer 1, a mechanical arm 3 disposed above the refueling platform 2, and a mechanical arm 3 disposed below the printer 1 Automatic unloading and refueling device 4; the automatic unloading and refueling device 4 includes a horizontal optical axis 5, a controller 6, a driver 7 and a refueling plate 9, the refilling plate 9 is used to accept the printing platform 14, and the printer 1 Located on the same level as the refueling platform 2, one end of the horizontal optical axis 5 is connected to the printer 1, and the other end is connected to the refueling platform 2. Preferably, there are two horizontal optical axes 5, and the two horizontal optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com