Preparation process method of N-methyl-1, 3-propane diamine

A preparation process and technology of propylene diamine are applied in the preparation of amino compounds, the preparation of organic compounds, the preparation of carboxylic acid nitrile, etc., and can solve the problems of complicated rectification and purification operations, low production efficiency, and low product yield, etc. Achieve the effect of reducing the probability of deterioration, improving hydrogenation efficiency, and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

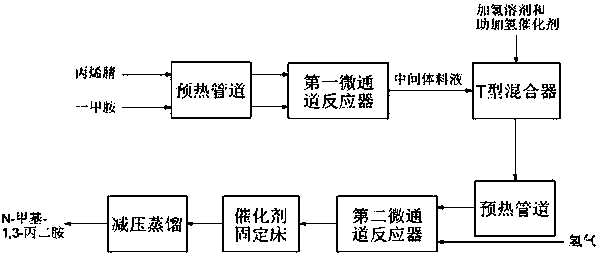

[0030] Through the metering pump, acrylonitrile and 40% monomethylamine aqueous solution are passed into the preheating pipeline at a molar ratio of 1:1, and the acrylonitrile and monomethylamine aqueous solution are preheated to 40°C respectively, and then the raw material liquid enters the first A microchannel reactor carries out addition reaction, reaction temperature 40 ℃, reaction time 90s, reaction pressure 0.5MPa, the reaction feed liquid containing intermediate 3-methylaminopropionitrile and water obtained after the completion of the reaction; the reaction feed liquid is directly Mix evenly with water containing sodium hydroxide through a T-type mixer, then heat the feed liquid to 100°C through a preheating pipeline, and pass it into the second microchannel reactor with a mixing ratio of 1:150 (v / v) with hydrogen Mix, then enter the fixed bed filled with Ranny-Ni for hydrogenation reaction, the content of 3-methylaminopropionitrile in the hydrogenation raw material liqu...

Embodiment 2

[0032] Using the production method of Example 1, the difference is to use a monomethylamine-methanol solution with a concentration of 80%, the molar ratio of acrylonitrile and monomethylamine is 1:2, the reaction temperature is 100°C, the reaction time is 50s, and the reaction pressure is 1.5MPa The hydrogenation solvent is methanol, the hydrogenation aid catalyst is monomethylamine, the content of 3-methylaminopropionitrile in the hydrogenation raw material liquid is 20%, the content of monomethylamine is 2%, the reaction temperature is 70°C, the reaction time is 5min, and the final product The yield is 93.5%.

Embodiment 3

[0034] Using the production method of Example 1, the difference is that the concentration of 95% monomethylamine aqueous solution is used, the molar ratio of acrylonitrile and monomethylamine is 1:1.3, the reaction temperature is 120°C, the reaction time is 30s, and the reaction pressure is 2.2MPa; The hydrogen solvent is water, and the hydrogenation-promoting catalyst is sodium carbonate and monomethylamine. The 3-methylaminopropionitrile content is 40% in the hydrogenation raw material liquid, and the co-catalyst content is 2%. The fixed bed is filled with Pd-C, and the hydrogenation reaction temperature is 90°C, the reaction time is 10min, and the yield of the final product is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com