Method for preparing alumina carrier with large pore volume

A technology of alumina carrier and large pore volume, which is applied to catalyst carriers, chemical instruments and methods, ceramic products, etc., can solve the problems of large consumption of acid and alkali, large loss of powder pore volume, and small pore volume of alumina carrier, etc. Achieve low wear, simple process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

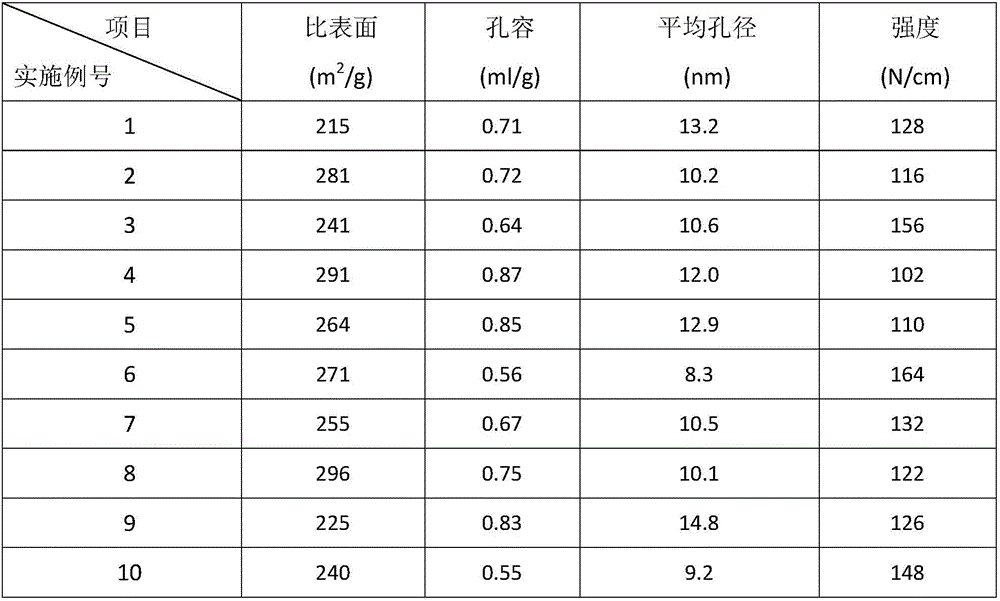

Embodiment 1

[0023] Fully mix 300g of amorphous alumina with a particle size of 12μm, 120g of urea and 150g of water, then put the mixed material into a ball mill and grind it for 12 hours, then take out the ground material, add 5g of Selina powder, add 150g of water, knead Kneading in the machine to obtain a plastic body, extruded through an orifice plate to make a 3mm cylinder, dried at 120°C for 8 hours, and calcined at 550°C for 5 hours to obtain a cylindrical alumina carrier, its specific surface, pore volume, pore size, particle size, The strength index is shown in Table 1.

Embodiment 2

[0025] Fully mix 300g of amorphous alumina with a particle size of 12μm, 90g of urea and 100g of water, then put the mixed material into a ball mill and grind it for 12 hours, then take out the ground material, add 5g of scallop powder, add 220g of water, knead Kneading in the machine to obtain a plastic body, extruded through an orifice plate to make a 3mm cylinder, dried at 120°C for 8 hours, and calcined at 550°C for 5 hours to obtain a cylindrical alumina carrier, its specific surface, pore volume, pore size, particle size, The strength index is shown in Table 1.

Embodiment 3

[0027] Fully mix 300g of amorphous alumina with a particle size of 20μm, 60g of urea and 60g of water, then put the mixed material into a ball mill and grind it for 24 hours, then take out the ground material, add 2g of sodium carboxymethylcellulose, and add 180g of water , kneaded in a kneader to obtain a plastic body, extruded through an orifice plate to make a 3mm cylinder, dried at 120°C for 8 hours, and calcined at 600°C for 5 hours to obtain a cylindrical alumina carrier. Its specific surface, pore volume, pore diameter, The particle size and strength index are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com