Magnetic inorganic nano corpuscle/zeolite nucleocapsid type composite microsphere and preparation method thereof

A technology of inorganic nanoparticles and magnetic nanoparticles, which is applied in the fields of magnetism of inorganic materials, treatment of inorganic pigments, chemical instruments and methods, etc., can solve the problems of no reports of inorganic magnetic nanoparticles/zeolite core-shell composite microspheres, etc., and the method is simple Rapid, high degree of crystallization, easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

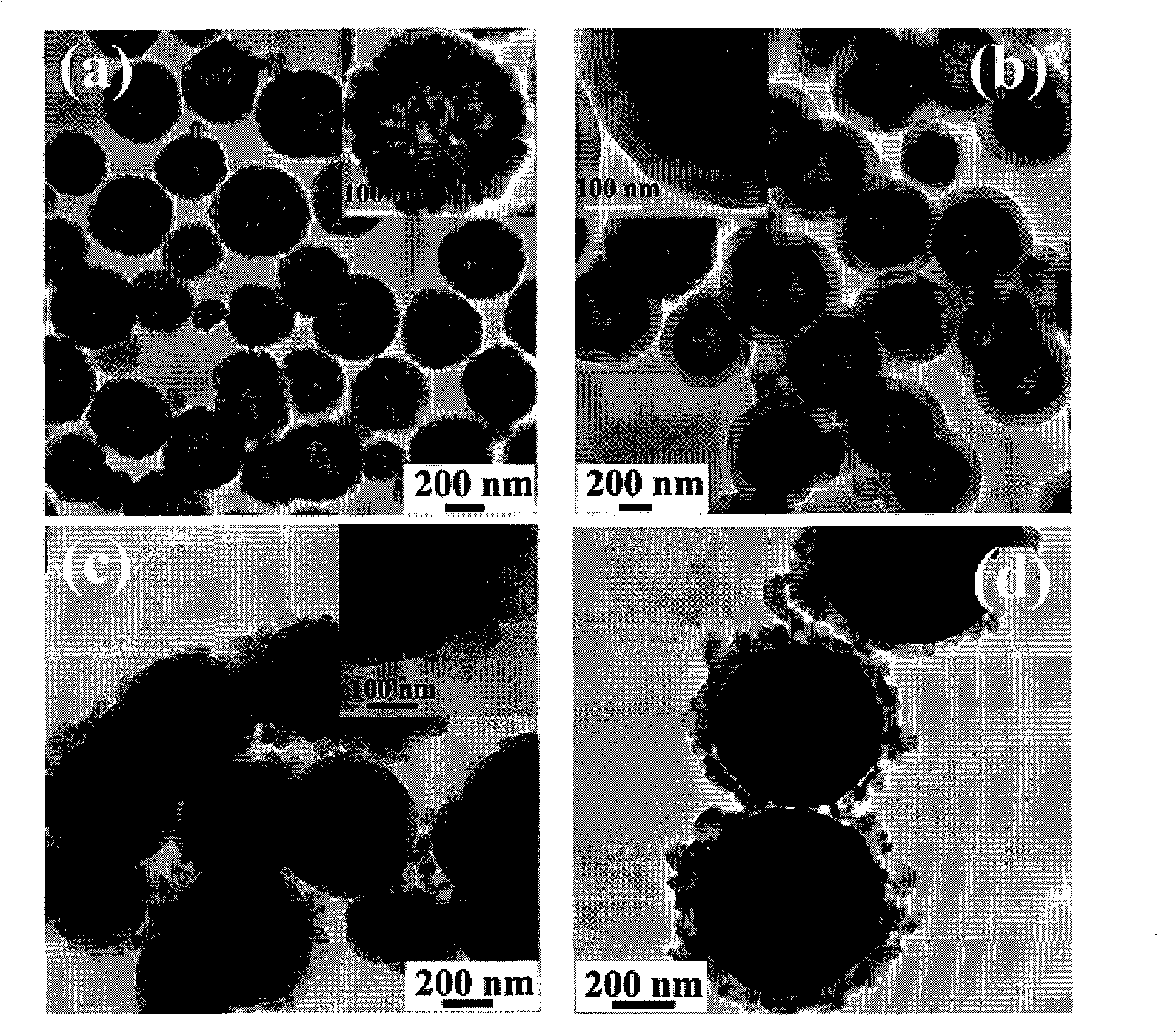

Embodiment 1

[0016] (1) 0.03g of superparamagnetic 500nm NiFe 2 o 4 The nano-microspheres were ultrasonically dispersed into 5ml 1M HCl solution for pretreatment, the magnetic particles were fully washed with deionized water, and then ultrasonically dispersed into a mixture of 100g ethanol, 30g deionized water and 1g concentrated ammonia water. Subsequently, 1.0 g TEOS was added and stirred for 12 h, and finally the product was separated by a magnet, washed with water and ethanol and dispersed into deionized water to obtain a stable dispersion (4.0 wt%) for later use.

[0017] (2) 5.0g of NiFe prepared above 2 o 4 @SiO 2 Microsphere dispersion and 1.0g polydimethyldiallylammonium chloride (PDDA) (Mw=20000g / mol) 1% aqueous solution are mixed, and PDDA is adsorbed on NiFe 2 o 4 @SiO 2 surface. Washing PDDA-adsorbed NiFe with 2.0% ammonia solution 2 o 4 @SiO 2 The microspheres were separated by a magnet, and after repeated 4 times, the NiFe adsorbed PDDA 2 o 4 @SiO 2 The microsph...

Embodiment 2

[0019] (1) 400nm 0.03g superparamagnetic γ-Fe 2 o 3 The nano-microspheres were ultrasonically dispersed into 5ml 2M HCl solution for pretreatment, the magnetic particles were fully washed with deionized water, and then ultrasonically dispersed into a mixture of 100g ethanol, 30g deionized water and 1g concentrated ammonia water. Subsequently, 2.0 g TEOS was added and stirred for 12 h, and finally the product was separated by a magnet, washed with water and ethanol and dispersed in deionized water to obtain a stable dispersion (5.0 wt%) for later use.

[0020] (2) 5.0g of γ-Fe prepared above 2 o 3 @SiO 2Microsphere dispersion and 2.0g polydimethyldiallylammonium chloride (PDDA) (Mw=20000g / mol) 1% aqueous solution are mixed, and PDDA is adsorbed to Fe 3 o 4 @SiO 2 surface. Wash the PDDA-adsorbed γ-Fe with 2.0% ammonia solution 2 o 3 @SiO 2 The microspheres were separated by a magnet, and after repeated 4 times, the γ-Fe adsorbed by PDDA 2 o 3 @SiO 2 The microspheres...

Embodiment 3

[0022] (1) 0.02g superparamagnetic Fe 3 o 4 The nano-microspheres were ultrasonically dispersed into 5ml 2M HCl solution for pretreatment, the magnetic particles were fully washed with deionized water, and then ultrasonically dispersed into a mixture of 100g ethanol, 30g deionized water and 1g concentrated ammonia water. Subsequently, 1.0 g TEOS was added and stirred for 12 h, and finally the product was separated by a magnet, washed with water and ethanol and dispersed into deionized water to obtain a stable dispersion (4.0 wt%) for later use.

[0023] (2) the 5.0g of Fe obtained above 3 o 4 @SiO 2 Microsphere dispersion and 2.0g polydimethyldiallylammonium chloride (PDDA) (Mw=20000g / mol) 1% aqueous solution are mixed, and PDDA is adsorbed to Fe 3 o 4 @SiO 2 surface. Wash the PDDA-adsorbed Fe with 2.0% ammonia solution 3 o 4 @SiO 2 The microspheres were separated by a magnet, and after repeated 4 times, the Fe adsorbed on PDDA 3 o 4 @SiO 2 The microspheres were d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com