Alpha-type semi-hydrated gypsum autoclave and production method thereof

A technology of hemihydrate gypsum and autoclave, applied in the field of autoclave, can solve the problems of high safety requirements, low product stability, poor toughness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

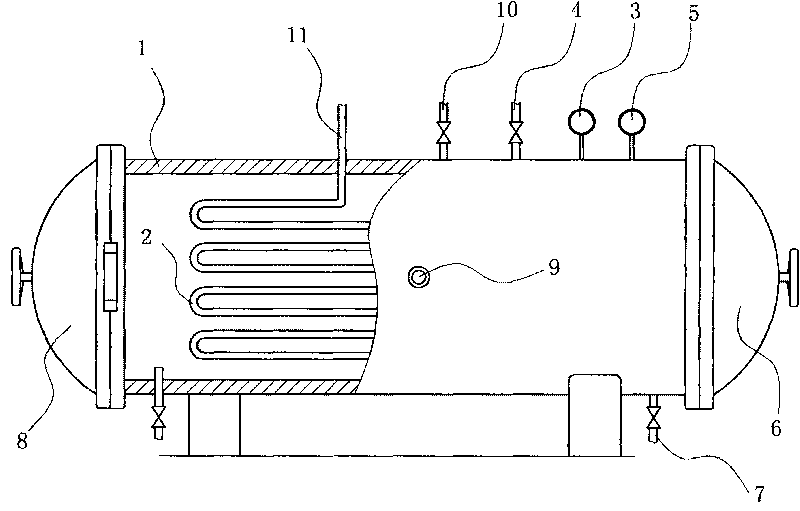

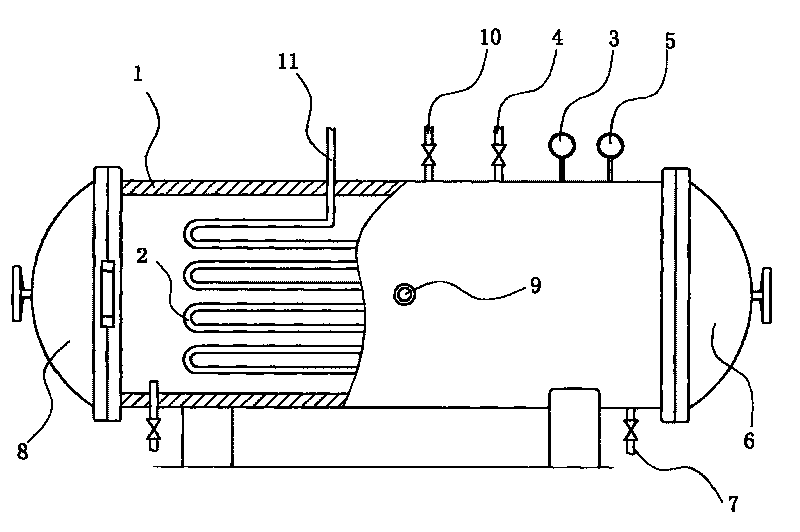

[0011] As shown in the accompanying drawings, the α-type hemihydrate gypsum autoclave includes a horizontal autoclave body 1, and the autoclave body 1 is provided with a feed end cover 6 and a discharge end cover 8. The autoclave A hot oil heating device 2 is installed on the inner cavity wall of the kettle body 1, and the hot oil heating device 2 is connected to the outside of the autoclave body 1 through a heat conduction oil pipe 11, and the autoclave body 1 is also equipped with Steam inlet 9, the autoclave body 1 is also provided with a steam outlet 4, and the bottom of the autoclave body 1 is provided with a water outlet 7. A pressure gauge 3 and a temperature gauge 5 are installed on the autoclave body 1 , and a safety valve 10 is installed on the autoclave body 1 .

[0012] The production method of α-type hemihydrate gypsum uses the α-type hemihydrate gypsum autoclave, adopts heat conduction oil and steam dual heat sources to heat, and dehydrates; puts gypsum ore into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com