Method for preparing mesoporous titanium dioxide

A technology of titanium source and alkoxy, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as pore collapse, specific surface area reduction, and mesoporous structure destruction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The said method of preparing mesoporous titanium dioxide of the present invention, it comprises the steps:

[0022] (1) Titanium source (preferably tetraethyl titanate, isopropyl titanate or n-butyl titanate), templating agent (compound shown in formula I) and C 2 ~C 6 Monohydric alcohol (preferably ethanol, isopropanol or n-butanol) is placed in a reactor with a stirring device, and under stirring conditions at 15°C to 25°C, add hydrochloric acid with a molar concentration of 4M dropwise to the reactor Until the pH value of the system is less than 2, after the hydrochloric acid is added, the resulting mixture is left to stand at 50°C for at least 24 hours to obtain a xerogel;

[0023] Wherein: the molar ratio of template agent to titanium should be controlled at (0.05-1):1, and the best molar ratio of template agent (compound shown in formula I) to titanium is 0.2:1.

[0024] (2) After calcining the dry gel obtained in step (1) at 400°C to 600°C for 1 hour to 5 hours...

Embodiment 1

[0029] Dissolve 3.2g of triethoxysilylpropyldimethyloctadecylammonium chloride in 60mL of isopropanol, then add 10mL of isopropyl titanate, stir for 1 hour, then add 10.6mL of molar Aqueous hydrochloric acid solution with a concentration of 4M is acidified until the pH value of the system is less than 2. After the dropwise addition was completed, stirring was continued for 1 h. The obtained sol was poured into a petri dish and aged at 50°C for 1 day to obtain a xerogel.

[0030] 4g of the obtained xerogel was heated in an air stream at a temperature of 1°C / min, and the temperature was raised to 400°C for 2 hours. Then it was cooled to room temperature at a rate of 10°C / min to obtain 1.45 g of white powder.

[0031] Take 1g of the above powder, put it into 10M aqueous sodium hydroxide solution, wash at 50°C for 2h, then wash with 10mL of water and ethanol three times, and dry in infrared at 60°C for 10h to obtain 0.86g of white powder (target).

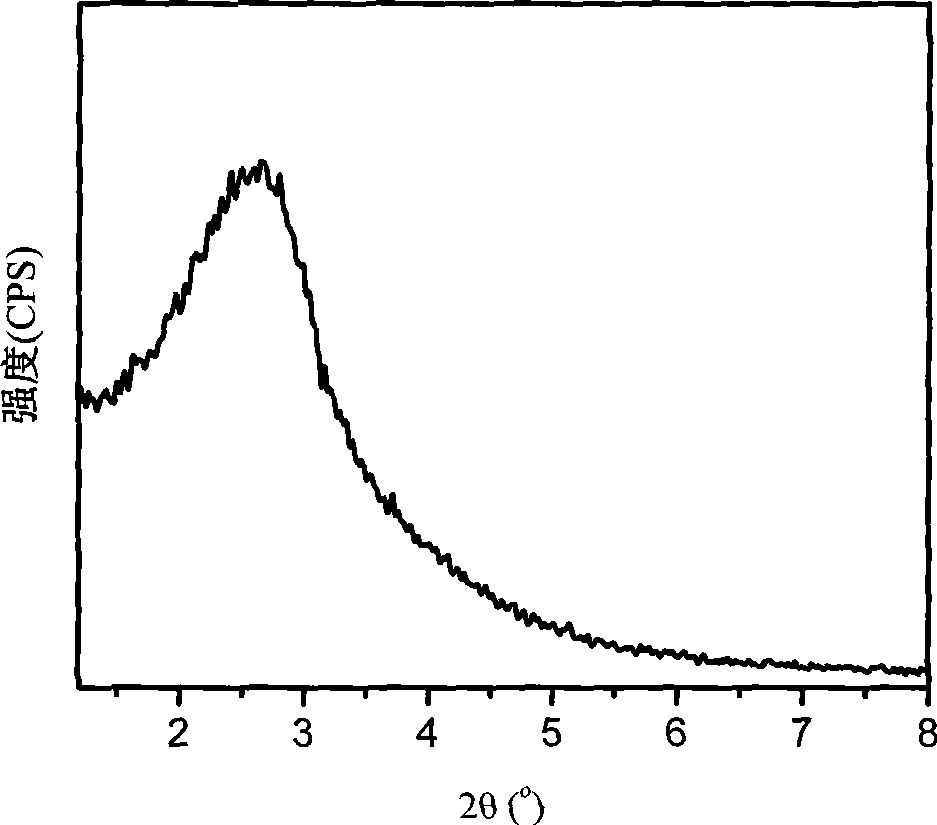

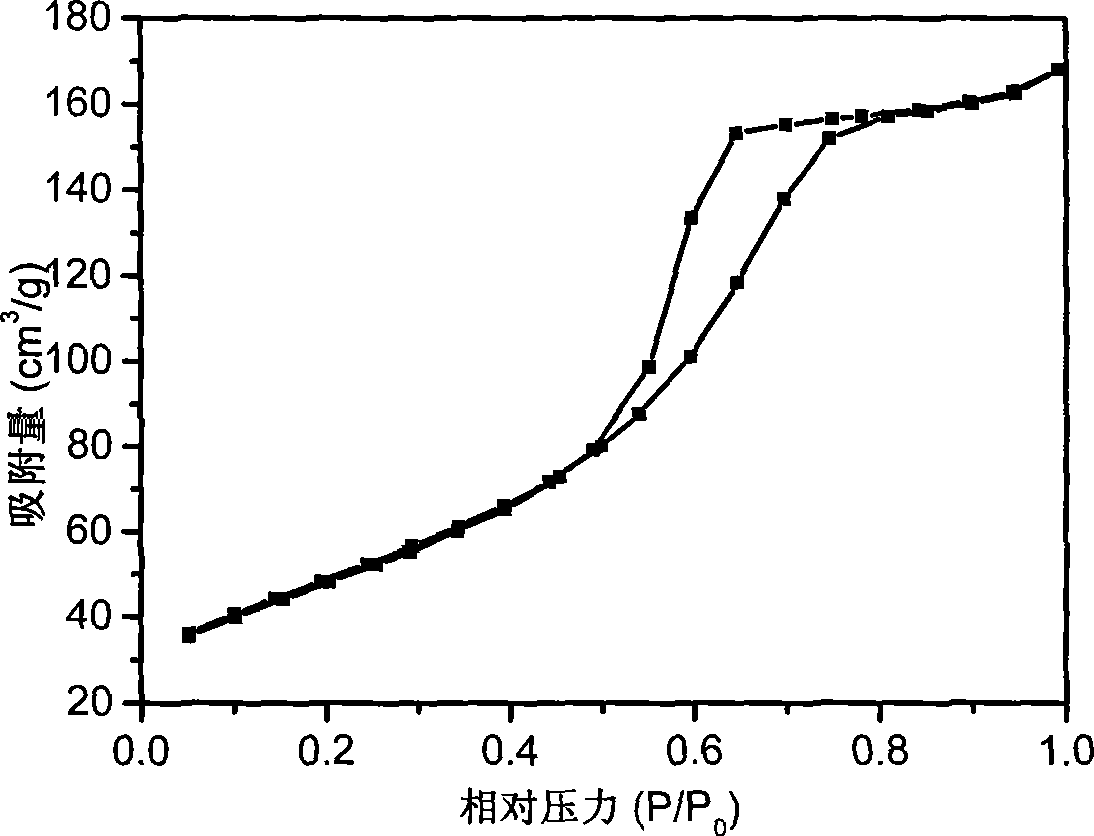

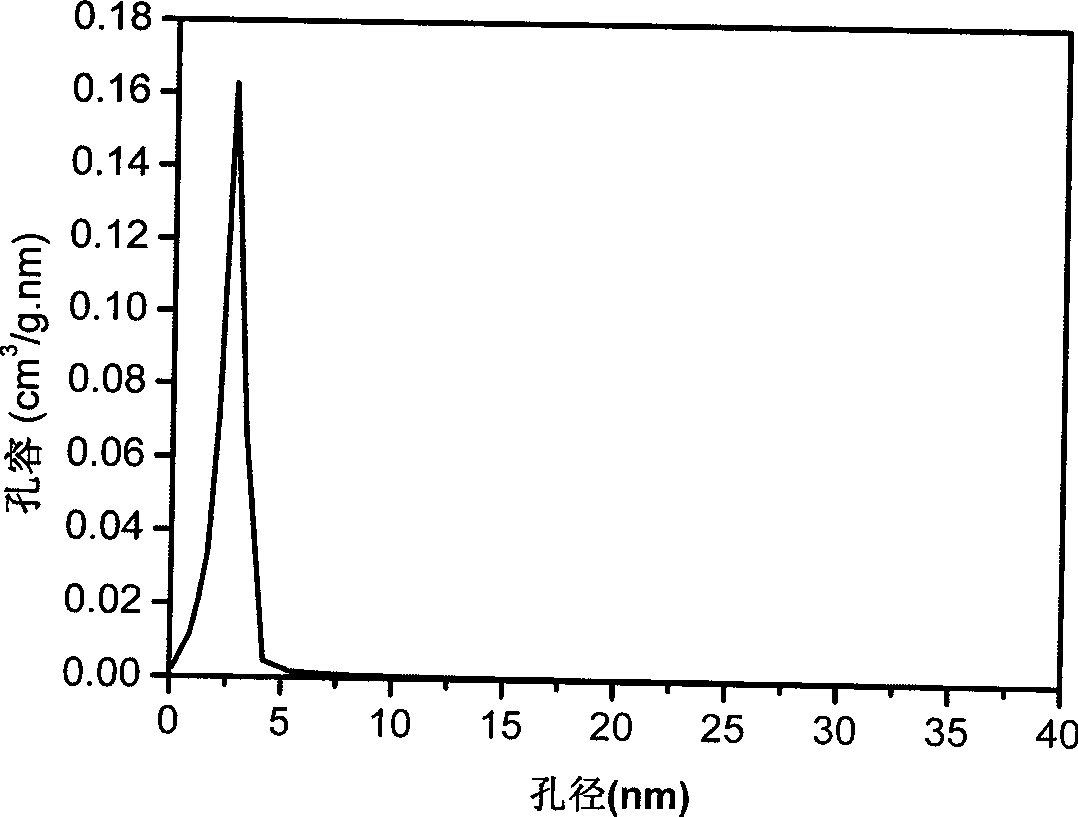

[0032] The small-angle X-ray...

Embodiment 2

[0037] Dissolve 7.3g of trimethoxysilylpropyl dimethyl octadecyl ammonium chloride in 88mL of n-butanol, then add 10mL of n-butyl titanate, stir for 1h, then add dropwise 10.6mL of molar concentration under vigorous stirring 4M aqueous hydrochloric acid acid until the pH of the system is less than 2. After the dropwise addition was completed, stirring was continued for 1 h. The obtained sol was poured into a petri dish and aged at 50°C for 1 day to obtain a xerogel.

[0038] 4 g of the obtained xerogel was heated in an air stream at a temperature of 1° C. / min, and the temperature was raised to 500° C. for 2 hours. Then it was cooled to room temperature at a rate of 10°C / min to obtain 1.16 g of white powder.

[0039] Take 1g of the above powder, put it into 5M aqueous sodium hydroxide solution, wash at 50°C for 24h, wash with 10mL of water and ethanol three times each, and dry in infrared at 60°C for 10h to obtain 0.74g of white powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com