Aluminum matrix-mesoporous alumina composite material and preparation method and application of aluminum matrix-mesoporous alumina composite material

A technology of mesoporous alumina and composite materials, applied in chemical instruments and methods, from carbon oxides to hydrocarbons, metal/metal oxides/metal hydroxide catalysts, etc., can solve problems such as mass transfer limitations, and achieve penetration The effect of high yield, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

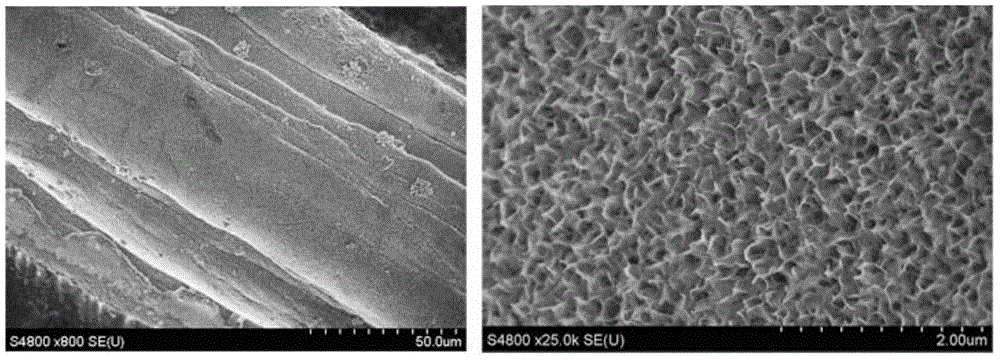

[0047] a) Weigh 5 grams of aluminum fiber (the fiber diameter is 80 microns, and the length is 5-10 mm), soak it with a sodium hydroxide aqueous solution with a concentration of 2.0 wt% at room temperature, wash it with distilled water, and dry it for later use;

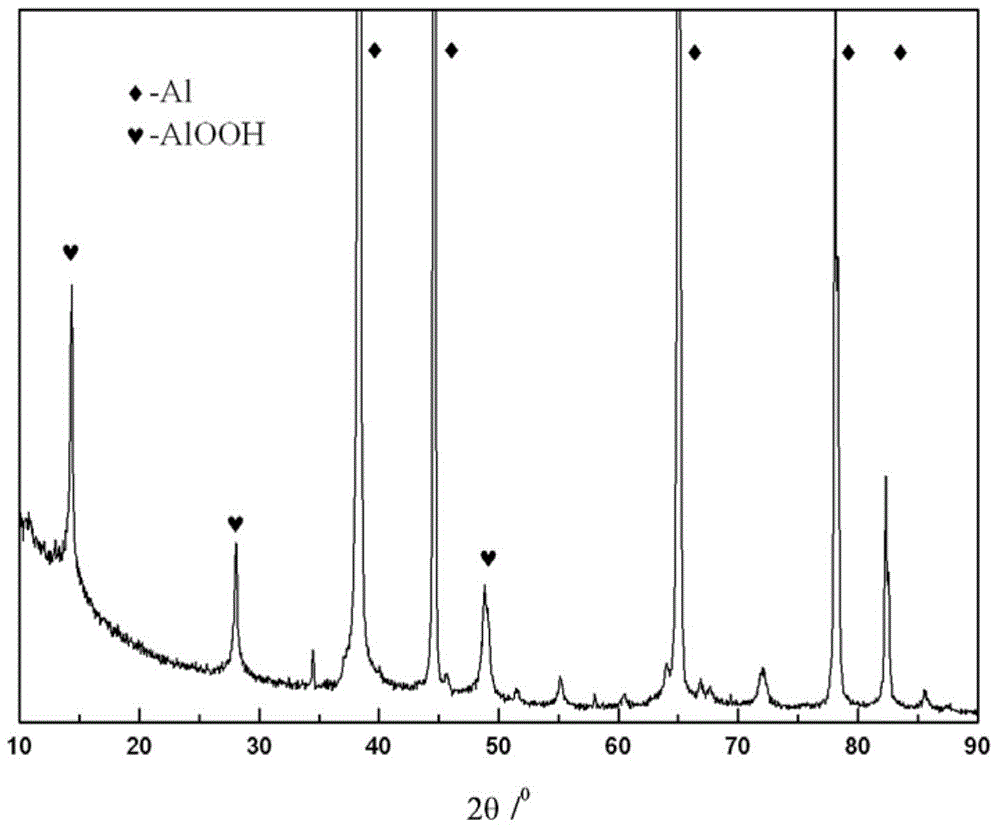

[0048] b) Put the aluminum fiber obtained in step a) into a 100 ml reaction kettle lined with polytetrafluoroethylene, add distilled water to completely submerge the aluminum fiber, seal the kettle and place it in an oven at 150°C for static hydrothermal treatment for 24 Hours, after washing with distilled water and drying, the aluminum matrix-mesoporous pseudo-boehmite composite material is obtained, which is recorded as: Al80-fiberAlOOH;

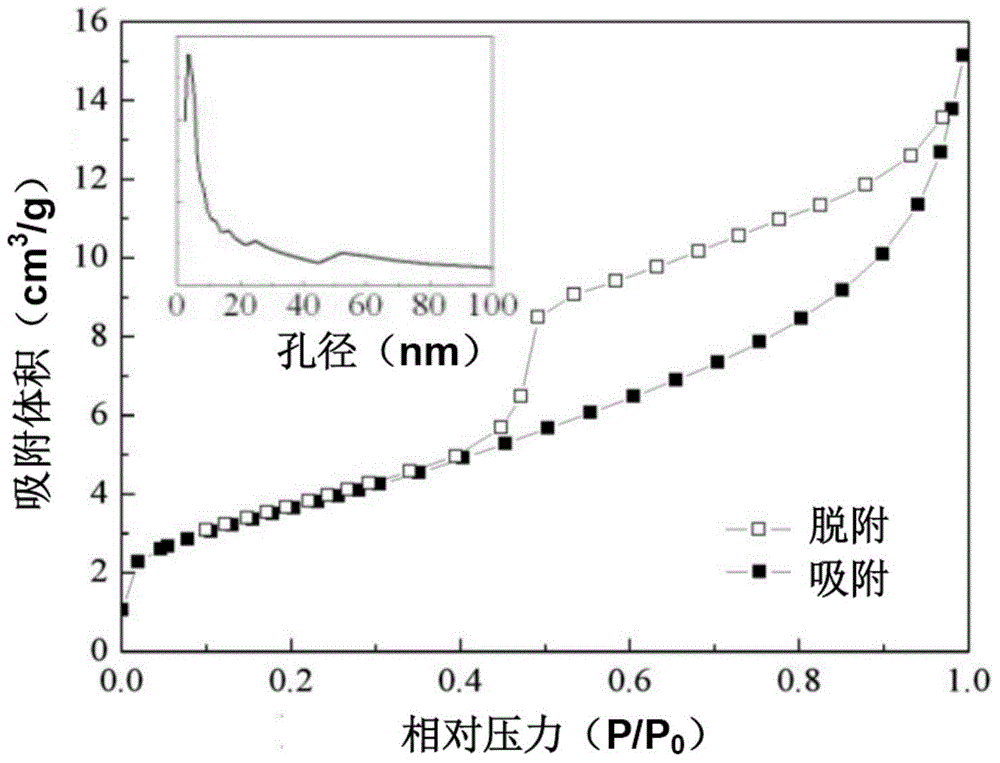

[0049] c) Calcining the Al80-fiberAlOOH obtained in step b) at 650°C in air for 0.5 hours to obtain the aluminum matrix-mesoporous alumina composite material, and the mesoporous alumina generated by weighing accounts for 4.6wt% of the total weight of the material , and the rest a...

Embodiment 2

[0056] a) Weigh 5 grams of aluminum fibers (the diameter of the fibers is 40 microns, and the length is 5 to 10 mm), soak them in an aqueous hydrochloric acid solution with a concentration of 1.0 wt % at room temperature, wash them with distilled water, and dry them for later use;

[0057] b) Put the aluminum fiber obtained in step a) into a 100 ml reaction kettle lined with polytetrafluoroethylene, add distilled water to completely submerge the aluminum fiber, seal the kettle and place it in an oven for static hydrothermal treatment at 180°C for 12 Hours, after washing with distilled water and drying, the aluminum matrix-mesoporous pseudo-boehmite composite material is obtained, which is recorded as: Al40-fiberAlOOH;

[0058] c) Calcining the Al40-fiberAlOOH obtained in step b) at 500°C in air for 8 hours to obtain the aluminum matrix-mesoporous alumina composite material, and the mesoporous alumina generated by weighing accounts for 15.3wt% of the total weight of the material...

Embodiment 3

[0063] a) Weigh 10 grams of aluminum wire (1.2 mm in diameter), soak it with a hydrochloric acid aqueous solution with a concentration of 1.0 wt% at room temperature, wash it with distilled water, and dry it for later use;

[0064] b) Put the aluminum wire obtained in step a) into a 100 ml reaction kettle lined with polytetrafluoroethylene, add distilled water to completely submerge the aluminum wire, seal the kettle and place it in an oven at 110°C for static hydrothermal treatment 72 Hours, after washing with distilled water and drying, the aluminum matrix-mesoporous pseudo-boehmite composite material is obtained, which is recorded as: Al-wireAlOOH;

[0065] c) Calcining the Al-wireAlOOH obtained in step b) at 600°C for 5 hours in the air to obtain the aluminum matrix-mesoporous alumina composite material, and the mesoporous alumina generated by weighing accounts for 5.6wt% of the total weight of the material , and the rest are aluminum matrix, so the obtained composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com