Method for preparing large-particle picromerite

A technology of magnesite and large particles, applied in the field of salt chemical industry, can solve the problems of easy agglomeration in drying, difficult separation of fine-grain magnesite, etc., and achieves the effects of high yield, low energy consumption and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

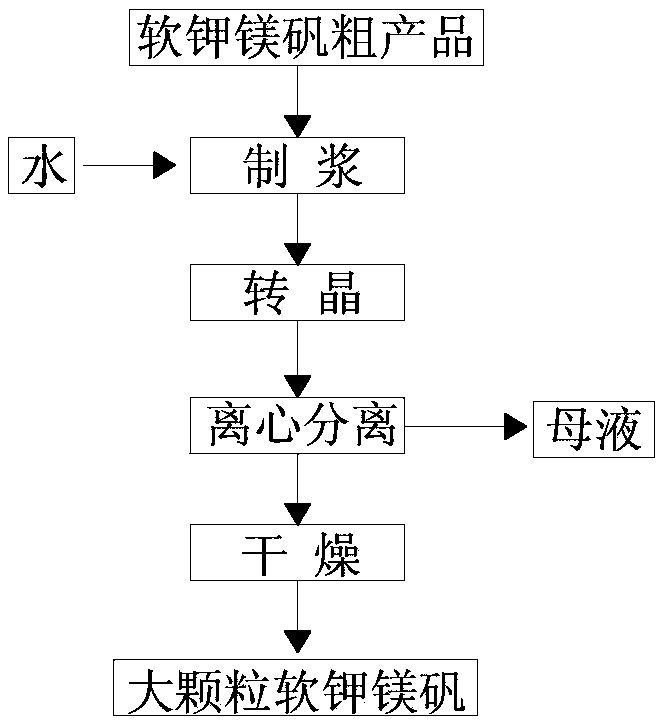

Method used

Image

Examples

Embodiment 1

[0024] The first step, pulping

[0025] Set the composition (mass percent) as: K + 19.00%, Mg 2+ 7.00%, Na + 0.80%, SO 4 2- 47.00%, Cl - 1.50% of the crude product of magnesite (the remaining components are water, and 1 to 2% of solid insoluble matter; the crude product is powder, with a particle size of less than 200 μm) and water in a mass ratio of 1:0.30 to prepare a slurry. The material temperature is controlled at 50℃;

[0026] The second step is to crystallize

[0027] The slurry obtained in the first step is continuously put into the mother liquor under the condition of 20°C in the continuous crystallizer, the temperature in the crystallizer is controlled to be kept at 20°C, and the mass ratio of Magnesite to the mother liquor in the crystallizer is controlled at 1:3 , and ensure that the injected slurry can have a residence time of 0.5 hours in the crystallizer, and the mass percentage concentration of ions contained in the composition of the mother liquor is: K...

Embodiment 2

[0035] The first step, pulping

[0036] Set the composition (mass percent) as: K + 17.08%, Mg 2+ 5.72%, Na + 1.67%, SO 4 2- 41.97%, Cl - 3.36% of the crude product of magnesite and water are prepared into a slurry in a mass ratio of 1:0.35, and the temperature of the slurry is controlled at 60°C;

[0037] The second step is to crystallize

[0038] The slurry obtained in the first step is continuously put into the mother liquor under the condition of 25°C in the continuous crystallizer, the temperature in the crystallizer is controlled to be kept at 25°C, and the mass ratio of Magnesite to the mother liquor in the crystallizer is controlled at 1:4.5 , and ensure that the injected slurry can have a residence time of 2.5 hours in the crystallizer, and the mass percentage concentration of ions contained in the composition of the mother liquor is: K + =4.59%, Mg 2+ =2.30%, Na + =1.60%, Cl - =4.75% and SO 4 2- =11.77%;

[0039] The third step, centrifugal separation

...

Embodiment 3

[0045] first step,

[0046] The composition (mass percentage) is: K + 16.00%, Mg 2+ 5.00%, Na + 2.00%, SO 4 2- 39.00%, Cl - 4.00% crude langbeinite and water are configured into a slurry at a mass ratio of 1:0.50, and the temperature of the slurry is controlled at 70°C;

[0047] The second step, cooling and crystallization

[0048] The slurry prepared in the first step is continuously put into the mother liquor at 30°C in the continuous crystallizer, the temperature in the crystallizer is kept at 30°C, and the mass ratio of kolinite and mother liquor in the crystallizer is controlled at 1:6 , and ensure that the slurry dropped into can have a residence time of 5 hours in the crystallizer, and the mass percent concentration of ions contained in the composition of the mother liquor is: K + =4.00%, Mg 2+ =2.00%, Na + =2.50%, Cl - =6.00% and SO 4 2- =11.00%;

[0049] The third step, centrifugation

[0050] The large-grain langbeinite obtained in the second step of crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com