Farm livestock waste and domestic waste co-utilization and heavy-metal control process

A technology for domestic waste and heavy metals, applied in the field of ecological environmental protection, can solve the problems of high energy consumption, poor incineration economy, heavy metal pollution, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

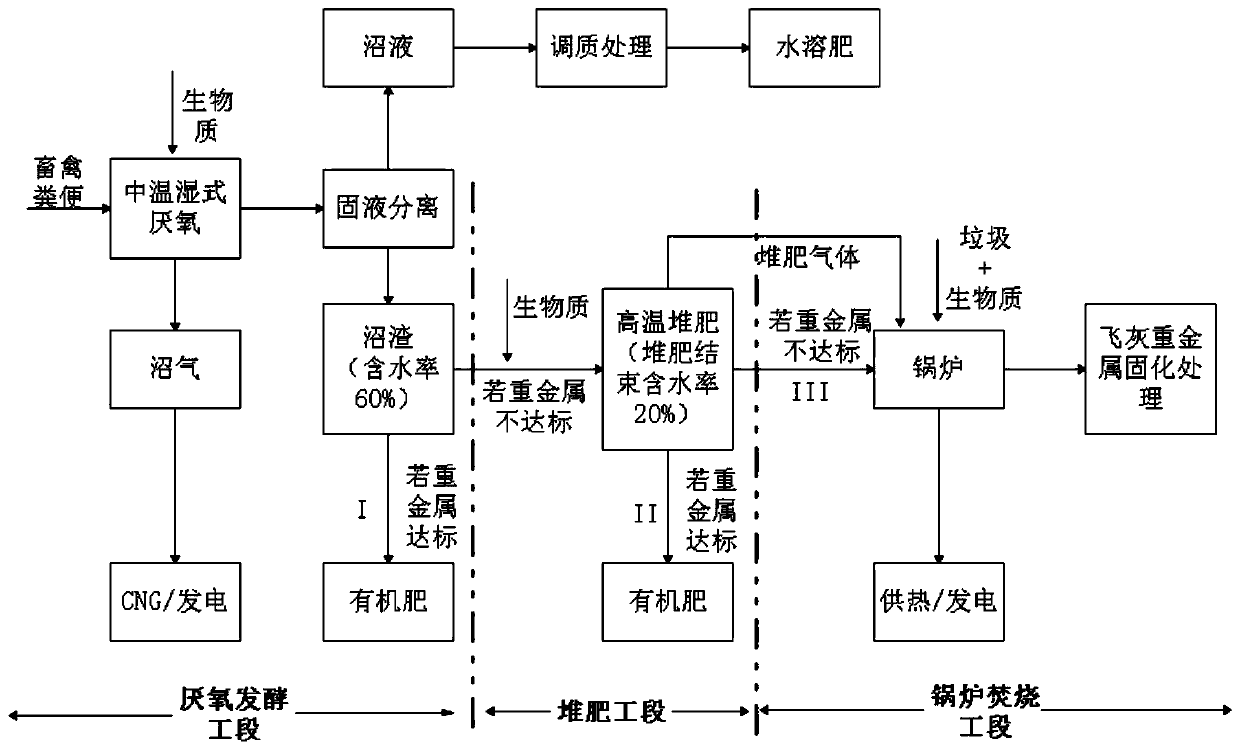

[0032] A process for synergistic utilization of agricultural and livestock waste and domestic waste and heavy metal control, such as figure 1 As shown, it consists of the following three parts: anaerobic fermentation section, composting section and boiler incineration section.

[0033] The concrete steps of described anaerobic fermentation workshop section are as follows:

[0034] Crush the corn stalks to 2.0mm. According to the TS content and element analysis results of pig manure and straw, mix corn stalks and fresh pig manure in proportion to adjust the C / N ratio to 27:1, add 20% inoculum, and add water as appropriate Adjust the water content to 90%, mix well and send it into the CSTR fermentation tank for 20 days of medium temperature and humidity anaerobic fermentation, and the fermentation will produce methane and residue.

[0035] The temperature of the mesophilic anaerobic fermentation is 33° C., and the pH is equal to 7.2.

[0036] The residue enters the filter pres...

Embodiment 2

[0046] A process for synergistic utilization of agricultural and livestock waste and domestic waste and heavy metal control, such as figure 1 As shown, it consists of the following three parts: anaerobic fermentation section, composting section and boiler incineration section.

[0047] The concrete steps of described anaerobic fermentation workshop section are as follows:

[0048] Crush the corn stalks to 2.5mm, mix the corn stalks and fresh cow manure in proportion to adjust the C / N ratio to 30:1 according to the TS content and elemental analysis results of cow dung and straw, add 20% inoculum, and add water as appropriate Adjust the water content to 92%, mix well and send it into the CSTR fermentation tank for 20 days of medium temperature and humidity anaerobic fermentation, and the fermentation will produce methane and residue.

[0049] The temperature of the mesophilic anaerobic fermentation is 35° C., and the pH is equal to 8.0.

[0050] The residue enters the filter p...

Embodiment 3

[0060] A process for synergistic utilization of agricultural and livestock waste and domestic waste and heavy metal control, such as figure 1 As shown, it consists of the following three parts: anaerobic fermentation section, composting section and boiler incineration section.

[0061] The concrete steps of described anaerobic fermentation workshop section are as follows:

[0062] Crush the wheat straw to 1.5mm, according to the TS content and elemental analysis results of the pig manure and straw, mix the wheat straw and fresh pig manure in proportion to adjust the C / N ratio to 25:1, add 20% inoculum, and add water as appropriate Adjust the water content to 88%, mix well and send it into the CSTR fermenter for 20 days of medium temperature and humidity anaerobic fermentation, and ferment to produce methane and residue.

[0063] The temperature of the mesophilic anaerobic fermentation is 35° C., and the pH is equal to 7.0.

[0064] The residue enters the filter press solid-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com