A kind of process method of producing solar grade polysilicon by sodium cycle method

A technology of solar energy level and process method, applied in the direction of polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve the problems of increasing production cost, environmental pollution, high energy consumption and high cost, and achieves wide and cheap raw material sources. , The effect of saving production costs and no toxic gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

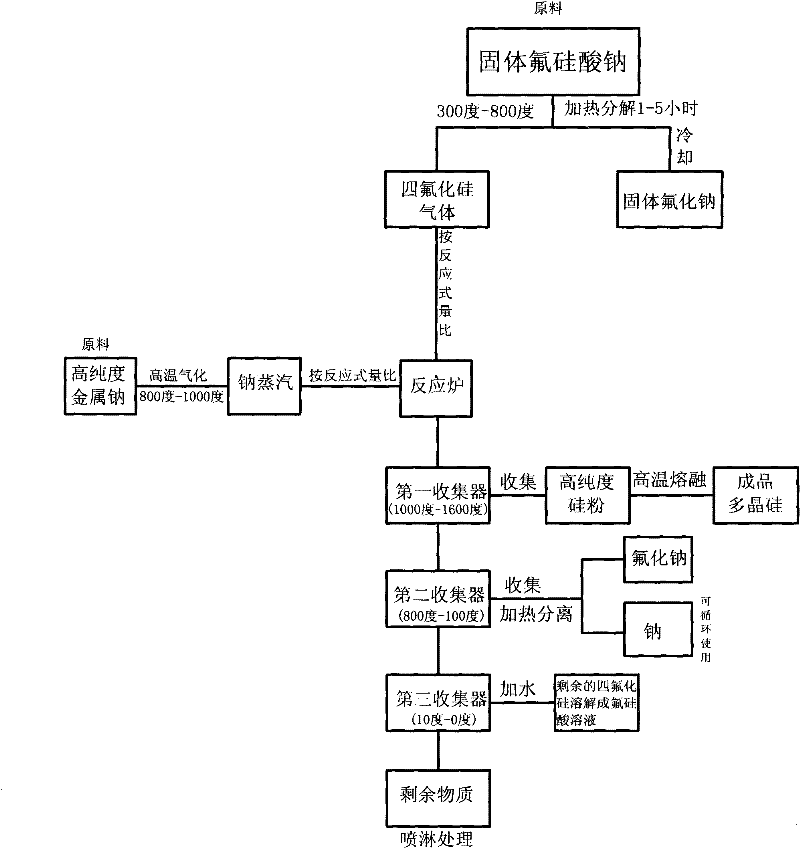

[0009] in the attached figure 1 Among them, the process of producing solar-grade polysilicon by the sodium circulation method is: put sodium fluorosilicate Na2SiF6 into the reactor, heat and decompose it at a temperature of 300°C-800°C for 1-5 hours, and generate silicon tetrafluoride SiF4 gas And the by-product sodium fluoride NaF, sodium fluoride NaF can be sold after cooling to become a solid; high-purity metal sodium Na is vaporized into sodium Na vapor at a high temperature of 800°C-1000°C in the reactor; at the same time, silicon tetrafluoride SiF4 The gas and high-purity sodium Na vapor enter the reaction furnace along the pipeline according to the ratio of 1:4 reaction formula to generate high-purity silicon powder; the high-purity silicon powder enters the first collector, and the temperature is controlled between 1000 ° C and 1600 ° C, and the powder The high-purity silicon Si is melted into blocks at high temperature to make polycrystalline silicon products; other m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com