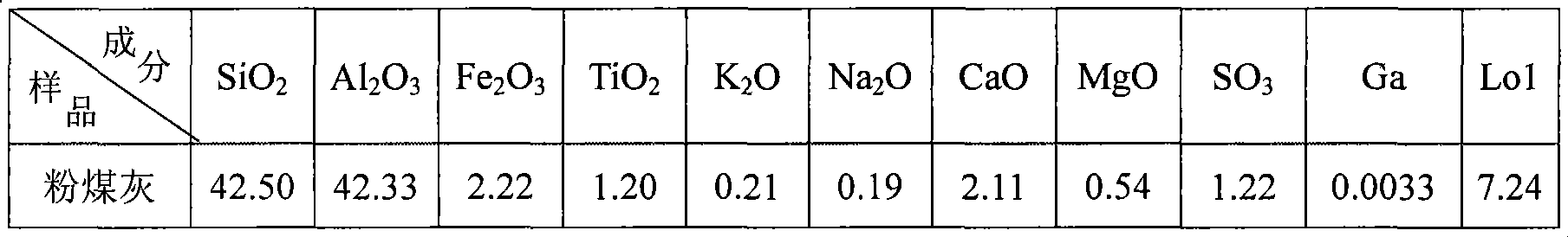

Method for extracting metal gallium from coal ash

A technology for extracting metals and fly ash, applied in the direction of improving process efficiency, etc., can solve problems such as complex process and loss of calcium and gallium aluminate, and achieve the effect of low cost and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

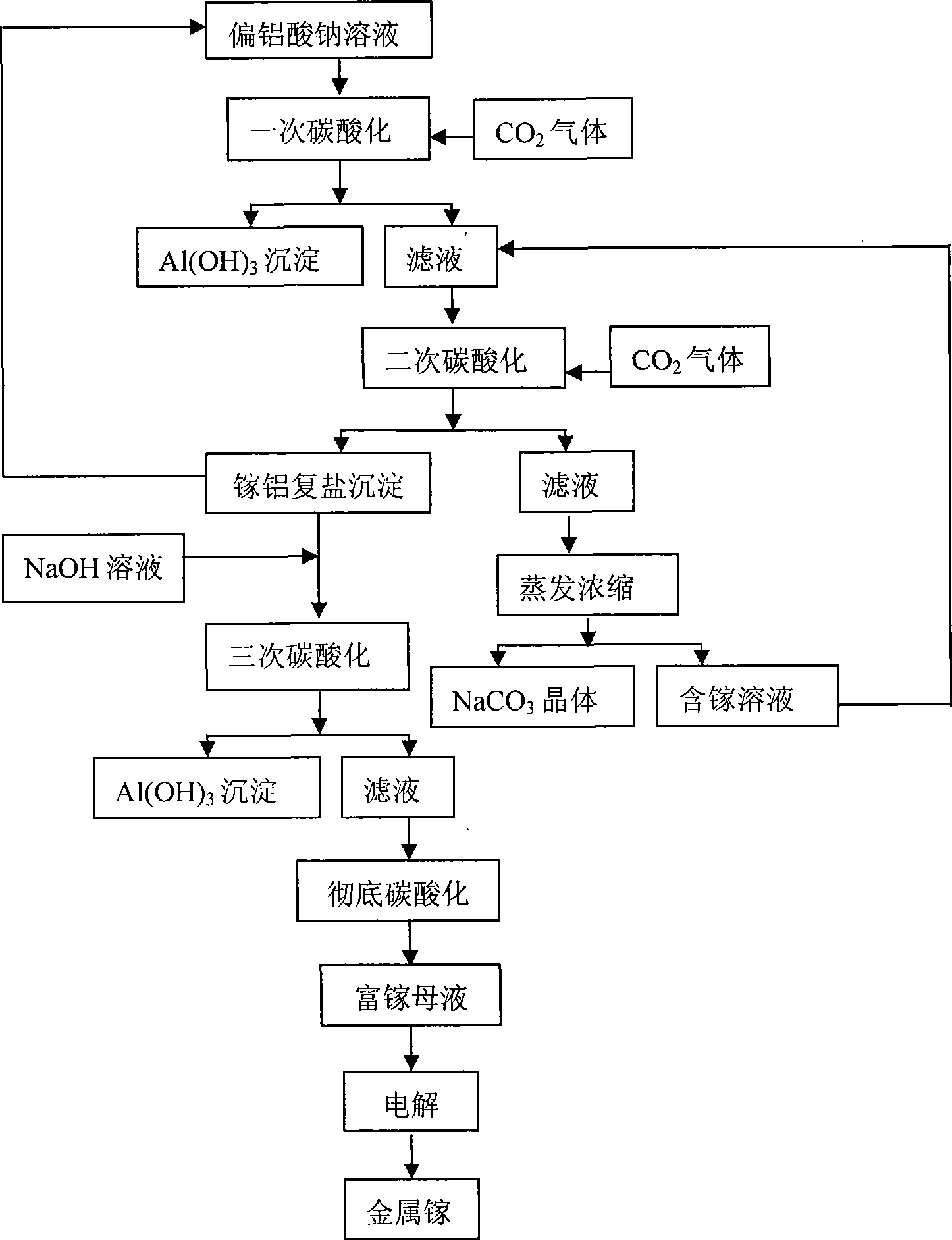

Method used

Image

Examples

Embodiment 1

[0020] At 60°C, feed CO into 100ml of sodium metaaluminate mother liquor at a rate of 90ml / min 2 Gas, carbonized for 5 hours, controlled pH = 10.6, filtered to complete a carbonation; after a carbonation to separate Al(OH) 3 The solution after precipitation is subjected to secondary carbonation. At 40°C, continue to feed CO at a rate of 120ml / min 2 gas, carbonization for 3h, control pH=9.0, and make Al(OH) 3 All precipitation, most of gallium precipitation, filtration to get aluminum gallium double salt precipitation, the filtrate is evaporated, concentrated, separated out sodium carbonate crystals, the solution after removing sodium carbonate is carbonized, and the aluminum gallium double salt obtained by secondary carbonation is dissolved in partial In the mother liquor of sodium aluminate, repeat the carbonization process once to realize the second separation of gallium and aluminum; after repeating the carbonation process once, separate Al(OH) 3 For the solution after p...

Embodiment 2

[0022] At 30°C, feed CO into 100ml of sodium metaaluminate mother liquor at a rate of 120ml / min 2 Gas, carbonized for 8 hours, controlled pH = 10, filtered to complete a carbonation; after a carbonation to separate Al(OH) 3 The solution after precipitation is subjected to secondary carbonation. At 50°C, continue to feed CO at a rate of 140ml / min 2 gas, carbonization for 4h, control pH=9.5, and make Al(OH) 3 All precipitation, most of gallium precipitation, filtration to get aluminum gallium double salt precipitation, the filtrate is evaporated, concentrated, separated out sodium carbonate crystals, the solution after removing sodium carbonate is carbonized, and the aluminum gallium double salt obtained by secondary carbonation is dissolved in partial In the mother liquor of sodium aluminate, repeat the carbonization process once to realize the second separation of gallium and aluminum; after repeating the carbonation process once, separate Al(OH) 3 For the solution after pr...

Embodiment 3

[0024] At 80°C, feed CO into 100ml of sodium metaaluminate mother liquor at a rate of 110ml / min 2 Gas, carbonized for 6 hours, controlled pH = 9.7, filtered to complete a carbonation; after a carbonation to separate Al(OH) 3 The solution after precipitation is subjected to secondary carbonation. At 60°C, continue to feed CO at a rate of 100ml / min 2 gas, carbonization for 3h, control pH=9.7, and make Al(OH) 3All precipitation, most of gallium precipitation, filtered to get aluminum gallium double salt precipitation, the filtrate is evaporated, concentrated, separated out sodium carbonate crystals, the solution after removing sodium carbonate is carbonized, the aluminum gallium double salt obtained by secondary carbonation is dissolved in partial In the mother liquor of sodium aluminate, repeat the process of carbonization once to realize the second separation of gallium and aluminum; repeat the process of carbonation to separate Al(OH) 3 For the solution after precipitation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com