Method for preparing heavy metal adsorbent by using modified bagasse

A technology of bagasse and heavy metals, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as soil fertility failure and destruction of ecological balance, and achieve reduction of secondary pollution, Low cost, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

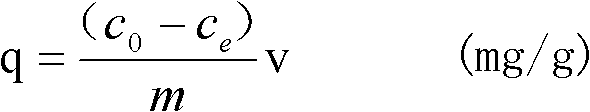

Method used

Image

Examples

Embodiment 1

[0023] After the bagasse is dried, it is crushed and passed through a 20-40 mesh sieve to obtain the bagasse powder. The bagasse powder is immersed in a potassium permanganate solution with a concentration of 1.0 g / L, stirred evenly, and nitrogen and oxygen are removed. React for 60 minutes, add acrylonitrile and N,N,-methylenebisacrylamide, pass nitrogen to remove oxygen again, react at 55°C for 57 minutes, add hydroquinone solution with a concentration of 10mg / L, and continue to react for 3 minutes , to obtain a reactant, the reactant was first washed with deionized water for 3 times, and then washed with 95% ethanol for 3 times, and then dried, filtered and dried to obtain the crude product of the heavy metal adsorbent. Among the above, the addition amounts of acrylonitrile, N, N,-methylenebisacrylamide and hydroquinone solution are respectively 0.2%; 2%; 0.075% of the weight of bagasse powder.

Embodiment 2

[0024] Example 2: The crude product of the heavy metal adsorbent was obtained according to the method of Example 1, and the crude product of the heavy metal adsorbent was extracted with N,N,-dimethylformamide at 140°C for 36 hours, and then used to remove Washing with deionized water for 3 times, and then washing with 95% ethanol for 3 times, draining and drying to obtain the fine product of the heavy metal adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com