Process technique for discharged doctor solution of HPF desulfurization system of coke-oven plant

A desulfurization system and treatment process technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of inability to meet the requirements of industrial products, difficult to achieve continuous regeneration, and unsuitable for the treatment of desulfurization liquid. Good economic and social benefits, novel research ideas, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

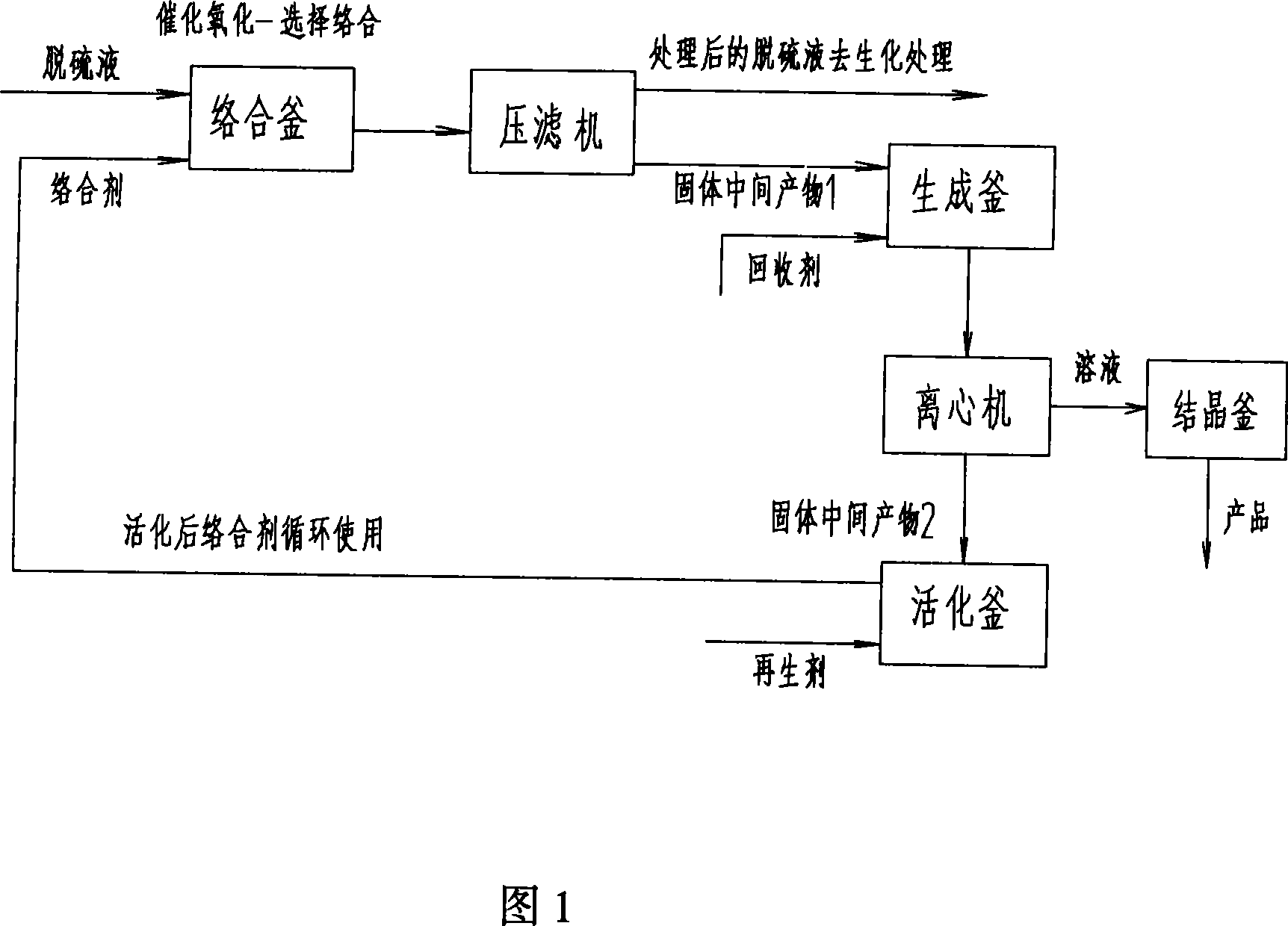

[0028] As shown in Figure 1, the complexing agent CuSO 4 . 5H 2 O was added to the complexing kettle, the temperature was adjusted to 20°C, the pH value was adjusted to -1 with sulfuric acid, and the desulfurization liquid was added at a ratio of 1:2.5, and the reaction pressure was set at 1 atm. The reaction that takes place in the complexing kettle is: (NH 4 ) 2 S 2 o 3 and (NH 4 ) 2 SO 3 is oxidized to (NH 4 ) 2 SO 4 , and the complexing agent is reduced at the same time, the complexing agent in the reduced state selects the SCN in the desulfurization solution -1 Ions generate a solid intermediate product—CuSCN. After the reaction is completed, the treated desulfurization liquid and solid intermediate product - CuSCN are separated by filter press. The desulfurization liquid enters the biochemical system for further treatment after ammonia distillation, and the solid intermediate product - CuSCN enters the product generation step.

[0029] The solid intermediate...

Embodiment 2

[0032] As shown in Figure 1, the complexing agent CuSO 4 . 5H 2 O was added to the complexing kettle, the temperature was adjusted to 30°C, the pH value was adjusted to 2 with sulfuric acid, and the desulfurization liquid was added at a ratio of 1:3.5, and the reaction pressure was set at 2atm. The reaction that takes place in the complexing kettle is: (NH 4 ) 2 S 2 o 3 and (NH 4 ) 2 SO 3 is oxidized to (NH 4 ) 2 SO 4 , and the complexing agent is reduced at the same time, the complexing agent in the reduced state selects the SCN in the desulfurization solution -1 Ions generate a solid intermediate product—CuSCN. After the reaction is completed, the treated desulfurization liquid and solid intermediate product - CuSCN are separated by filter press. The desulfurization liquid enters the biochemical system for further treatment after ammonia distillation, and the solid intermediate product - CuSCN enters the product generation step.

[0033] The solid intermediate p...

Embodiment 3

[0036] As shown in Figure 1, the complexing agent CuSO 4 . 5H 2 O was added to the complexing kettle, the temperature was adjusted to 50°C, the pH value was adjusted to 3 with sulfuric acid, and the desulfurization liquid was added in a ratio of 1:4.5, and the reaction pressure was set at 5atm. The reaction that takes place in the complexing kettle is: (NH 4 ) 2 S 2 o 3 and (NH 4 ) 2 SO 3 is oxidized to (NH 4 ) 2 SO 4 , and the complexing agent is reduced at the same time, the complexing agent in the reduced state selects the SCN in the desulfurization solution -1 Ions generate a solid intermediate product—CuSCN. After the reaction is completed, the treated desulfurization liquid and solid intermediate product - CuSCN are separated by filter press. The desulfurization liquid enters the biochemical system for further treatment after being distilled with ammonia, and the solid intermediate product - CuSCN enters the product generation step.

[0037] The solid interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com