High-activity kalium group solid absorbing agent for removing CO2 in flue gas and preparation method thereof

An absorbent and high-activity technology, applied in the field of flue gas purification, can solve the problems of adverse effects of active components, poor mechanical properties of diatomite, and poor regeneration performance of absorbents, and achieve easy automation, low price, and stable performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of absorbent is completed through five steps:

[0039] The first step, the preparation of potassium bicarbonate solution. Weighing potassium bicarbonate with a content of 20-50% of the total mass of the absorbent, and dissolving it with excess water;

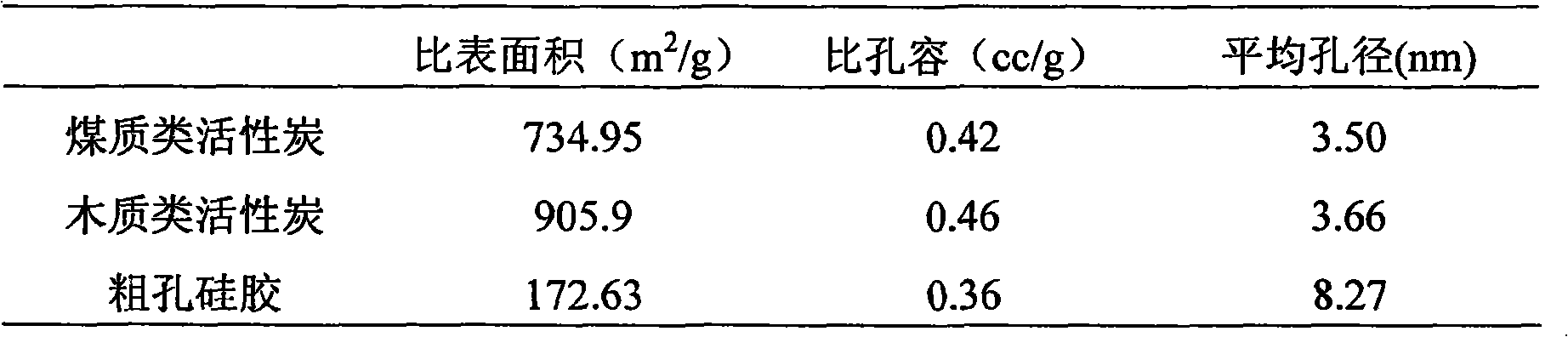

[0040] In the second step, the active ingredient is mixed with the carrier. Weigh granular coal-based activated carbon, wood activated carbon, or coarse-pore silica gel with a content of 50-80% of the total mass of the absorbent and a diameter of 0.3-0.8 mm, put it into a potassium bicarbonate solution, and stir on a stirrer for 8- 12h;

[0041] The third step is drying. Let the absorbent after stirring and mixing stand for 10-30 minutes. After the solid particles settle, remove excess liquid and dry at a temperature of 70-110°C;

[0042] The fourth step is roasting. Keep the dried absorbent at a temperature of 300-400°C for 2-3 hours;

Embodiment 1

[0046] Weigh 500kg of potassium bicarbonate and pour it into the mixer container, pour water into the container, and stir at the same time to completely dissolve the potassium bicarbonate; weigh 1000kg of granular woody activated carbon with a diameter of 0.35-0.45mm and pour it into the potassium bicarbonate solution and stir 10h, make it fully mixed; let the absorbent after stirring and mixing stand for 30min, after the solid particles settle, remove the excess liquid, pour the solid mixture into the heating furnace, set the temperature in the furnace to 90-105°C, and dry for 1h; Then raise the furnace temperature to 300°C-400°C, keep the temperature for 2 hours for roasting; sieve the roasted samples, and keep the samples between 0.35-0.45mm.

Embodiment 2

[0048] Weigh 500kg of potassium bicarbonate and pour it into the mixer container, pour water into the container, and stir at the same time to completely dissolve the potassium bicarbonate; weigh 1000kg of granular coal-based activated carbon with a diameter of 0.3-0.4mm and pour it into the potassium bicarbonate solution Stir for 10 hours to make it fully mixed; let the absorbent after stirring and mixing stand for 30 minutes, after the solid particles settle, remove excess liquid, pour the solid mixture into the heating furnace, set the temperature in the furnace to 90-105°C, and dry for 1 hour ; Then raise the furnace temperature to 300°C-400°C, keep the temperature for 2 hours for roasting; sieve the roasted samples, and keep the samples between 0.3-0.4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com