Device and method for producing hydrogen through coal gasification

A hydrogen production device and coal gasification technology, applied in the direction of granular/powdered fuel gasification, production of combustible gas, selection of absorbent solid gas purification, etc., can solve the problem of quality degradation, unsatisfactory effect, and optimal reaction temperature limitation and other issues to achieve the effect of reducing sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below with reference to the accompanying drawings.

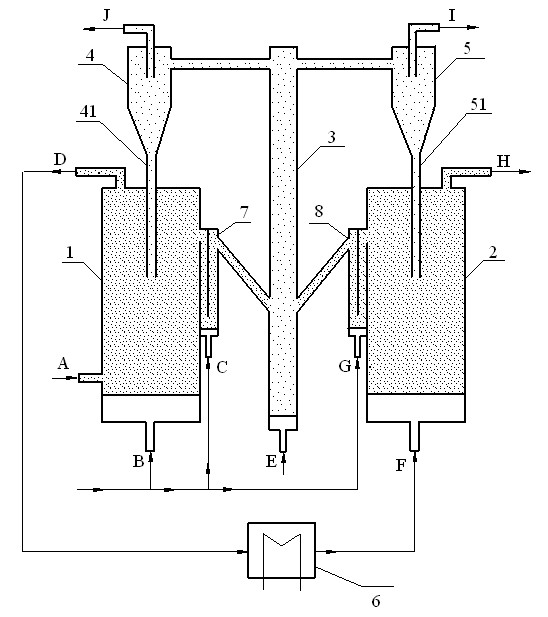

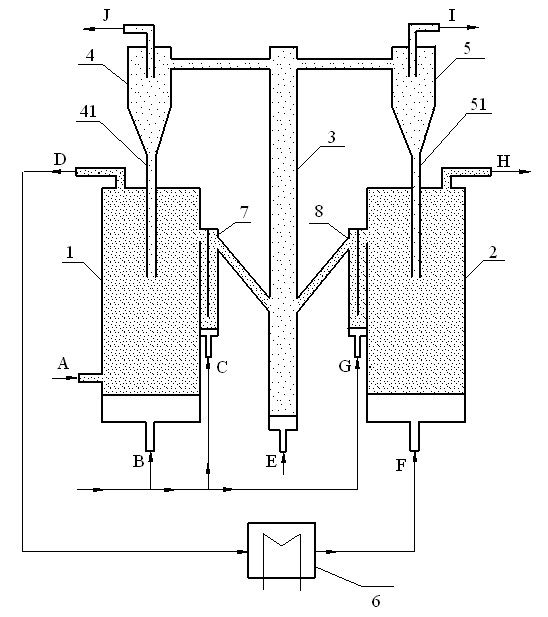

[0021] see figure 1 , the coal gasification hydrogen production device provided by the present invention includes a gasification reactor 1, an adsorption reactor 2 arranged opposite the gasification reactor 1, and a calcination reactor arranged between the gasification reactor 1 and the adsorption reactor 2 3. Gasification cyclone separator 4, adsorption cyclone separator 5, external heat exchanger 6, gasification isolator 7 and adsorption isolator 8.

[0022] The lower part of the gasification reactor 1 is provided with an inlet A for coal particles and a first inlet B for steam; the lower part of the gasification separator 7 is provided with a second inlet C for water vapor, and the upper part of the gasification reactor 1 is provided with There is an exhaust port D for high temperature synthesis gas, the lower part of adsorption reactor 2 is provided with an air inlet F for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com