Preparation method of carbon dioxide composite calcium-base absorbent

A composite calcium-based, carbon dioxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of decreased carbonation conversion rate of absorbent, aggravated heating surface wear, and increased fresh absorbent, etc. Excellent pore distribution characteristics, improving the recycling rate, and enhancing the effect of carbonation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

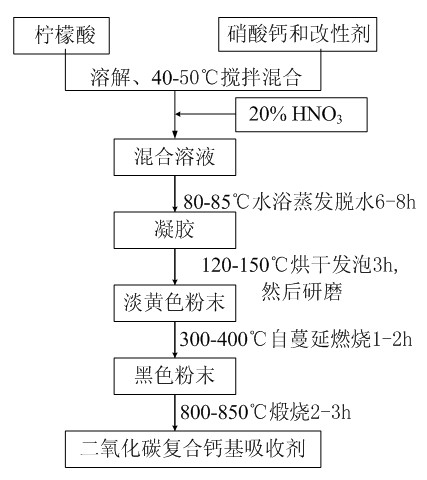

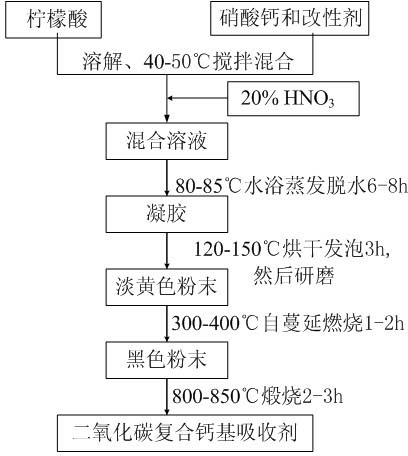

[0018] According to the molar ratio of calcium and magnesium as n (Ca) :n (Mg) =10:0.75-10:1.5, n (金属离子) :n (柠檬酸) = 1:1 Weigh appropriate amount of calcium nitrate, magnesium nitrate and citric acid, add to H 2 O-C 2 h 5 OH mixed solvent, stir in a magnetic stirrer at 40-50°C until the drug is completely dissolved; then add an appropriate amount of HNO with a concentration of 20% 3 Solution, magnetically stirred for 5-10 minutes; put the stirred solution in a water bath at 80-85°C, evaporate and dehydrate for 6-8 hours to form a gel sample; put it in an oven at 140°C to dry and foam for 3 hours, and grind Finely obtain a light yellow powder; transfer it into a muffle furnace and burn at 300°C for 1-2 hours to obtain a black powder; after grinding, calcinate at 800-850°C for 3 hours to obtain a white powder and obtain a magnesium-modified carbon dioxide composite calcium-based absorbent .

Embodiment approach 2

[0020] According to the mass molar ratio of calcium and manganese as n (Ca) :n (Mn) =100:1-100:2.5, n (金属离子) :n (柠檬酸) = 1:1 Weigh appropriate amount of calcium nitrate, manganese nitrate and citric acid, add to H 2 O-C 2 h 5 OH mixed solvent, stir in a magnetic stirrer at 40-50°C until the drug is completely dissolved; then add an appropriate amount of HNO with a concentration of 20% 3 Solution, magnetically stirred for 5-10 minutes; put the stirred solution in a water bath at 80-85°C, evaporate and dehydrate for 6-8 hours to form a gel sample; put it in an oven at 130°C to dry and foam for 3 hours, and grind Finely obtain a light yellow powder; move it into a muffle furnace and burn at 300°C for 1-2 hours to obtain a black powder; after grinding, calcinate at 800-850°C for 3 hours to obtain a light pink powder that is manganese-modified carbon dioxide composite calcium-based absorption agent.

Embodiment approach 3

[0022] According to the mass molar ratio of calcium and titanium as n (Ca) :n (Ti) =10:0.5-10:1.25, n (Ca) :n (柠檬酸) = 1:1 Weigh an appropriate amount of citric acid, calcium nitrate and butyl titanate, add to H 2 O-C 2 h 5 OH mixed solvent, stir in a magnetic stirrer at 40-50°C until the drug is completely dissolved; then add an appropriate amount of HNO with a concentration of 20% 3 Solution, magnetically stirred for 5-10 minutes; put the stirred solution in a water bath at 80-85°C, evaporate and dehydrate for 6-8 hours to form a gel sample; put it in an oven at 150°C to dry and foam for 3 hours, and grind Finely obtain light yellow powder; transfer to a muffle furnace and burn at 300°C for 1-2 hours to obtain a black powder; after grinding, calcinate at 800-850°C for 3 hours to obtain a white powder and obtain titanium-modified carbon dioxide composite calcium-based absorbent .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com