Method for preparing lube oil detergent of calcium nitrate in high base number

A high-basic value calcium sulfonate and lubricating oil technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of difficult control of product quality, wide particle size distribution, long reaction time, etc., and achieve easy scale-up, raw material Low consumption, high yield and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

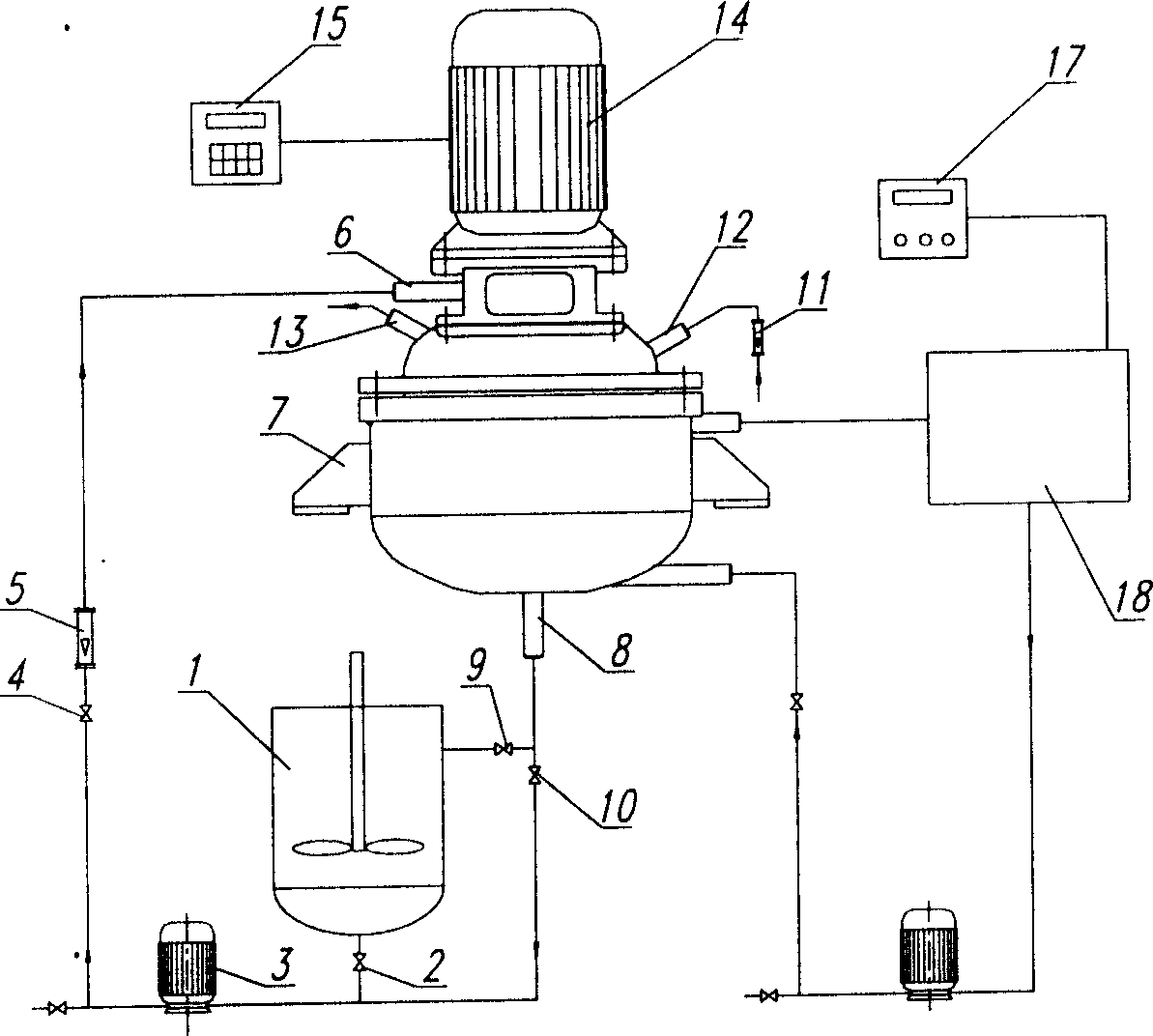

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: be 30-35% petroleum ammonium sulfonate, 995 gram calcium hydroxide, 4000 gram organic solvent, 600 gram methyl alcohol with 3000 gram content, after mixing, pour in circulation tank 1 and use pump 3 in liquid circulation Next, enter the rotating bed from the liquid inlet 6 of the rotating bed through the liquid flowmeter 5, close the valve 10, open the valve 9, and make the reaction material circulate in the rotating bed through the circulating tank, the liquid circulation flow rate is 2m / s, and start to heat up , when the temperature reaches 55°C, carbon dioxide gas is introduced according to the gas / liquid ratio of 0.05, the rotating speed of the rotating bed is 450rpm, and the reactants are released after 50 minutes of reaction, and the dealcoholized water is distilled under reduced pressure, diluted with solvent, centrifuged to remove slag, and reduced After a series of treatments such as pressure distillation and desolventization, the alkali value is 3...

Embodiment 2

[0022] Embodiment 2: be 30-35% petroleum ammonium sulfonate, 1330 gram calcium hydroxide, 4984 gram organic solvent, 1200 gram methyl alcohol with 4000 gram content, pour in the circulation tank after mixing, liquid circulation mode is with embodiment 1, The liquid circulation flow rate is 0.5m / s, and the temperature starts to rise. When the temperature reaches 50°C, carbon dioxide gas is introduced according to the gas / liquid ratio of 18, and the rotation speed of the rotating bed is 800rpm. After 30 minutes of reaction, the reactant is released, and it is distilled under reduced pressure. After a series of treatments such as dealcoholized water, centrifugal deslagging, vacuum distillation and desolventization, the alkali value is 310mgKOH / g, and the kinematic viscosity (100°C) is 50mm 2 / s, the effective component content is 54%, and the turbidity is 15JTU. The high-performance high-alkaline value calcium sulfonate lubricating oil detergent, the reaction time is at least 75% ...

Embodiment 3

[0023] Embodiment 3: be 35%-40% petroleum ammonium sulfonate, 1330 gram calcium hydroxide, 4984 gram organic solvent, 1200 gram methyl alcohol with 4000 gram content, pour in the circulation tank after mixing, in liquid circulation with pump 3 Under the action, enter the rotating bed from the liquid inlet 6 of the rotating bed through the liquid flowmeter 5, then close the valve 9, open the valve 10 to make the reaction material circulate directly in the rotating bed, the liquid circulation flow rate is 1m / s, and start to heat up, When the temperature reaches 40°C, carbon dioxide gas is introduced according to the gas / liquid ratio of 9, the rotation speed of the rotating bed is 900rpm, and the reactant is released after 45 minutes of reaction, and the dealcoholized water is distilled under reduced pressure, the slag is removed by centrifugation, and the solvent is removed by distillation under reduced pressure After a series of treatments, the alkali value is 290mgKOH / g, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com