Application of carbonatation steel scoria in wastewater treatment

A technology for carbonating steel slag and wastewater treatment, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic process treatment, etc., to achieve the effect of reducing emissions, saving equipment costs, and saving pharmaceutical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

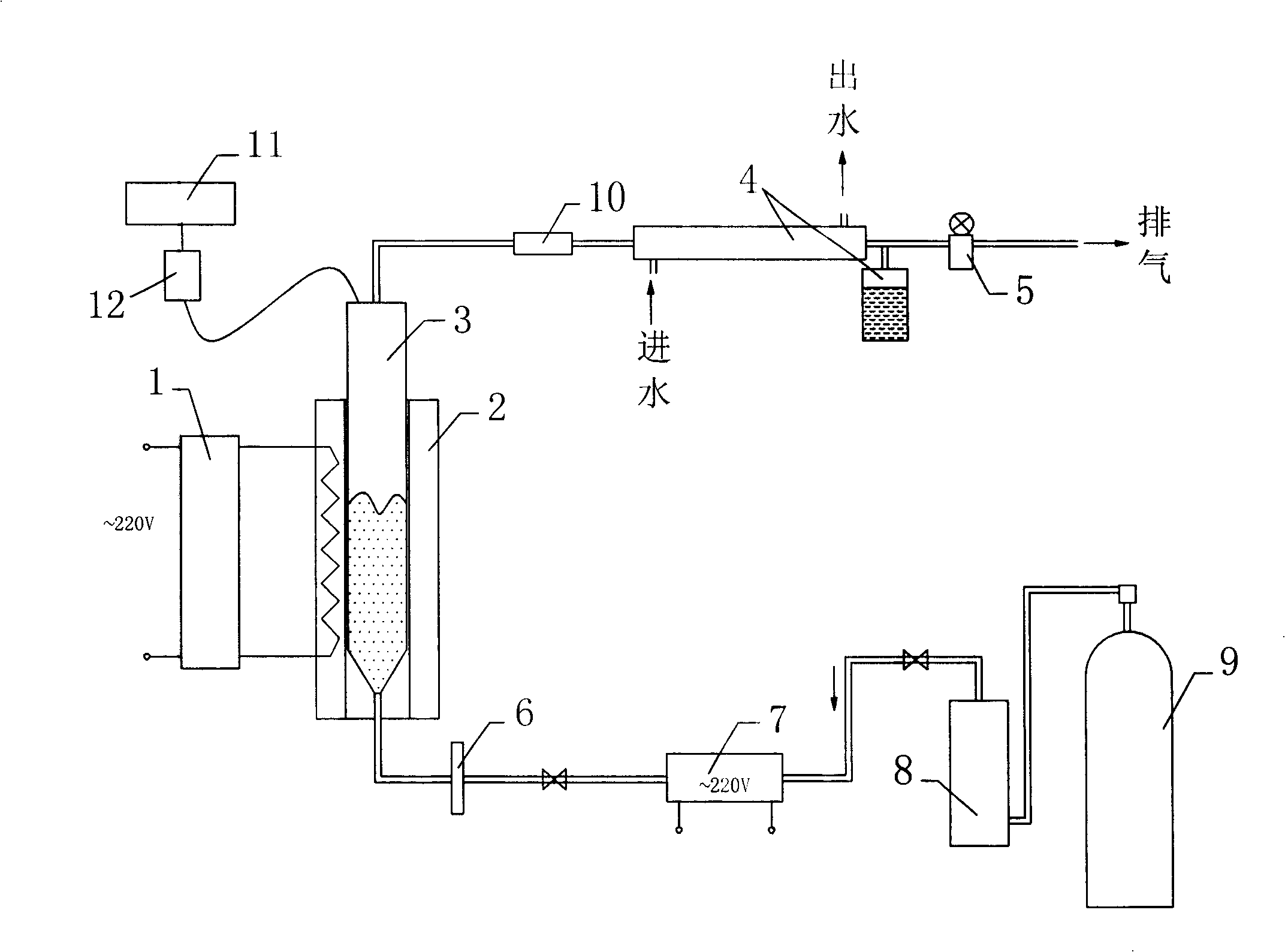

Method used

Image

Examples

Embodiment 1

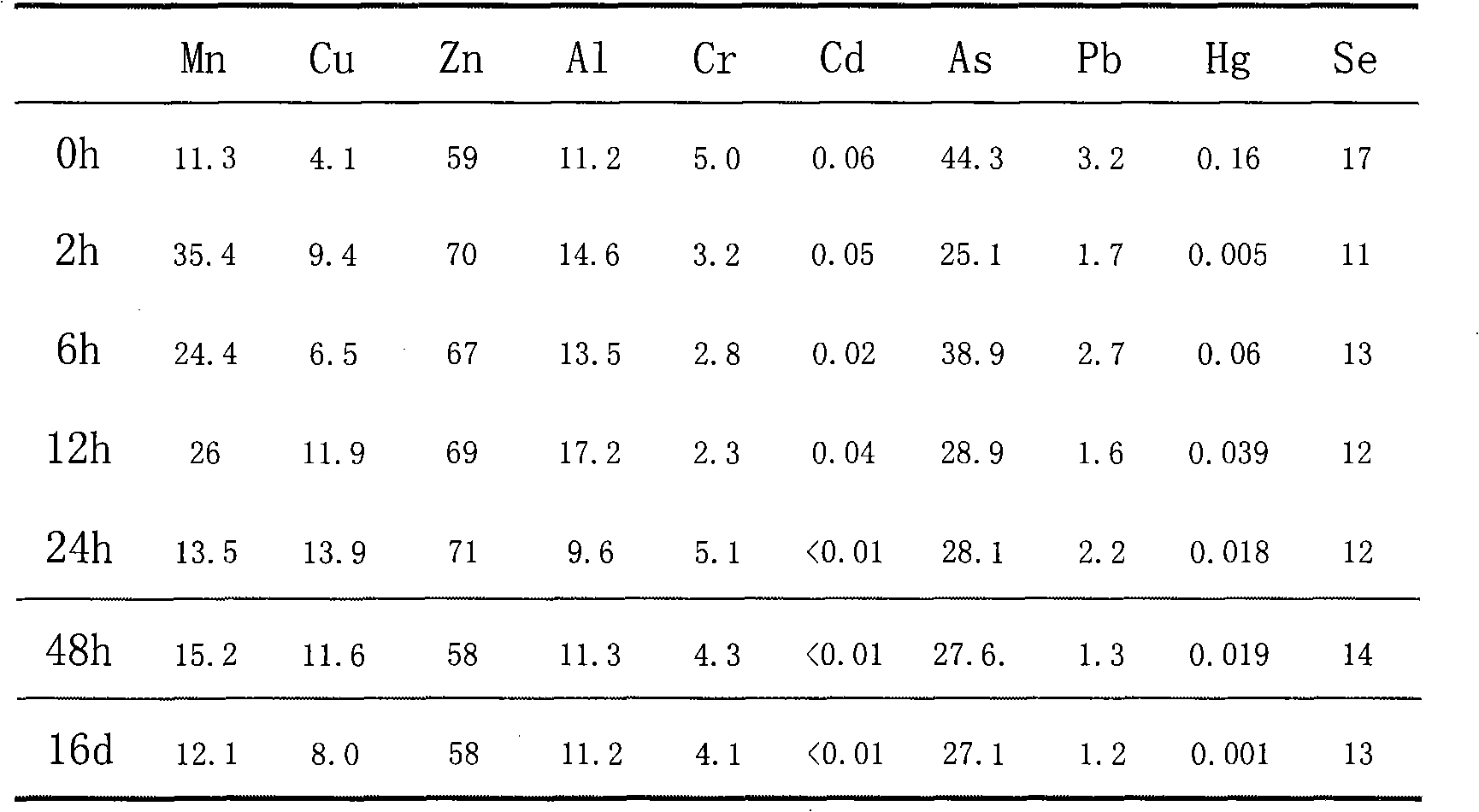

[0054] Table 1 lists the pH values of the water eluate before and after carbonation of converter steel slag.

[0055] Table 1 Comparison of pH value of water eluate before and after carbonation of converter steel slag

[0056] pH value

Embodiment 2

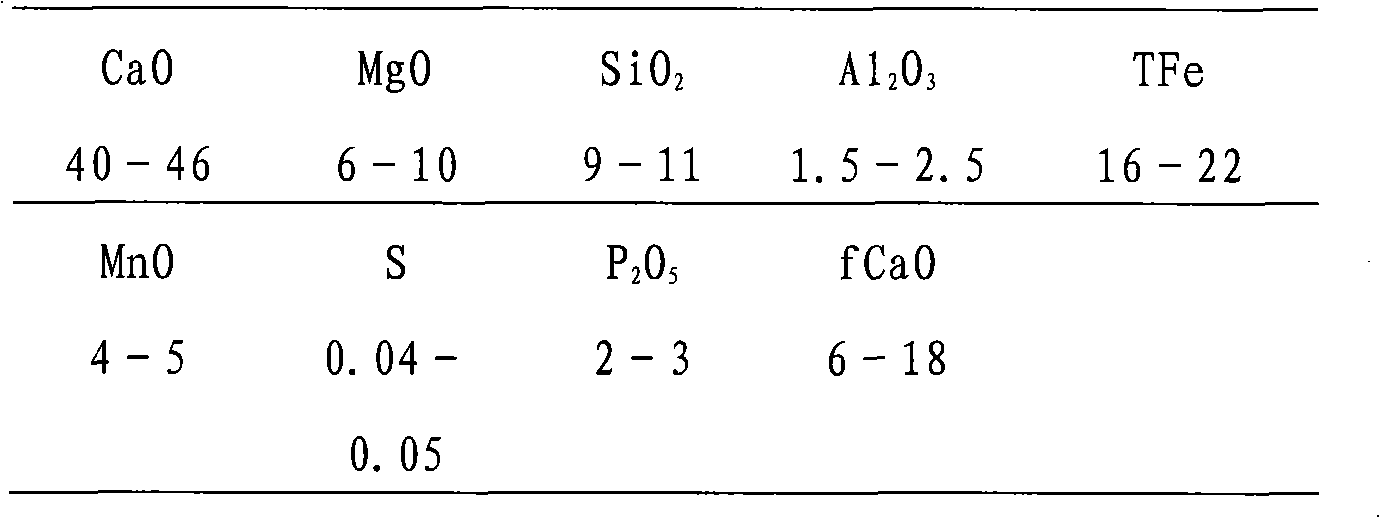

[0058] Metal element determination was carried out on the carbonation converter steel slag aqueous solution, and the results are shown in Table 2.

[0059] Table 2 Dissolution test results of converter steel slag in water after carbonation Unit: μg / L

[0060]

[0061] It can be seen from the data in the table that the concentration of environmentally sensitive metal elements dissolved in the water after carbonation of steel slag is far lower than the first-level discharge standard in the "Comprehensive Wastewater Discharge Standard GB8978-1996", which proves that carbonated steel slag is non-toxic and harmless. It can be used safely in water treatment to achieve resource utilization.

Embodiment 3

[0063] The dissolution law of iron in carbonated steel slag has been studied (see Table 3 for details). The research results show that iron ions in carbonated steel slag have a certain degree of dissolution in water, which is roughly 3-7 mg / L, which can basically meet the microbial growth process. demand for iron.

[0064] Table 3 Dissolution test results of iron in water in carbonated steel slag

[0065] time (d)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com