Cold steel scoria processing method

A technology of slag treatment and cold steel, applied in grain treatment, chemical instruments and methods, magnetic separation, etc., can solve the problems of waste, incomplete separation of metal materials, low degree of automation, etc., achieve high efficiency, improve labor intensity and The effect of working environment and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

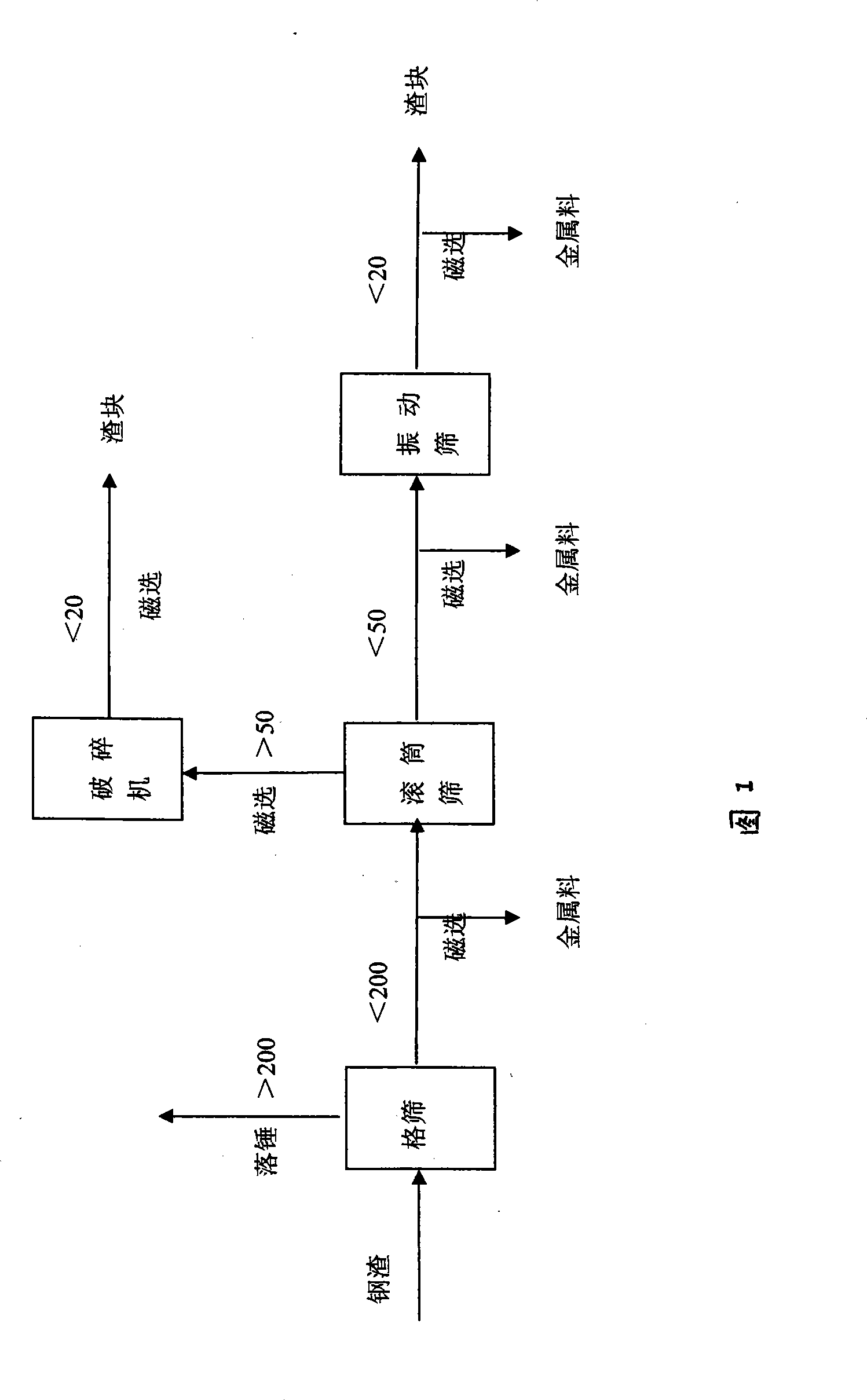

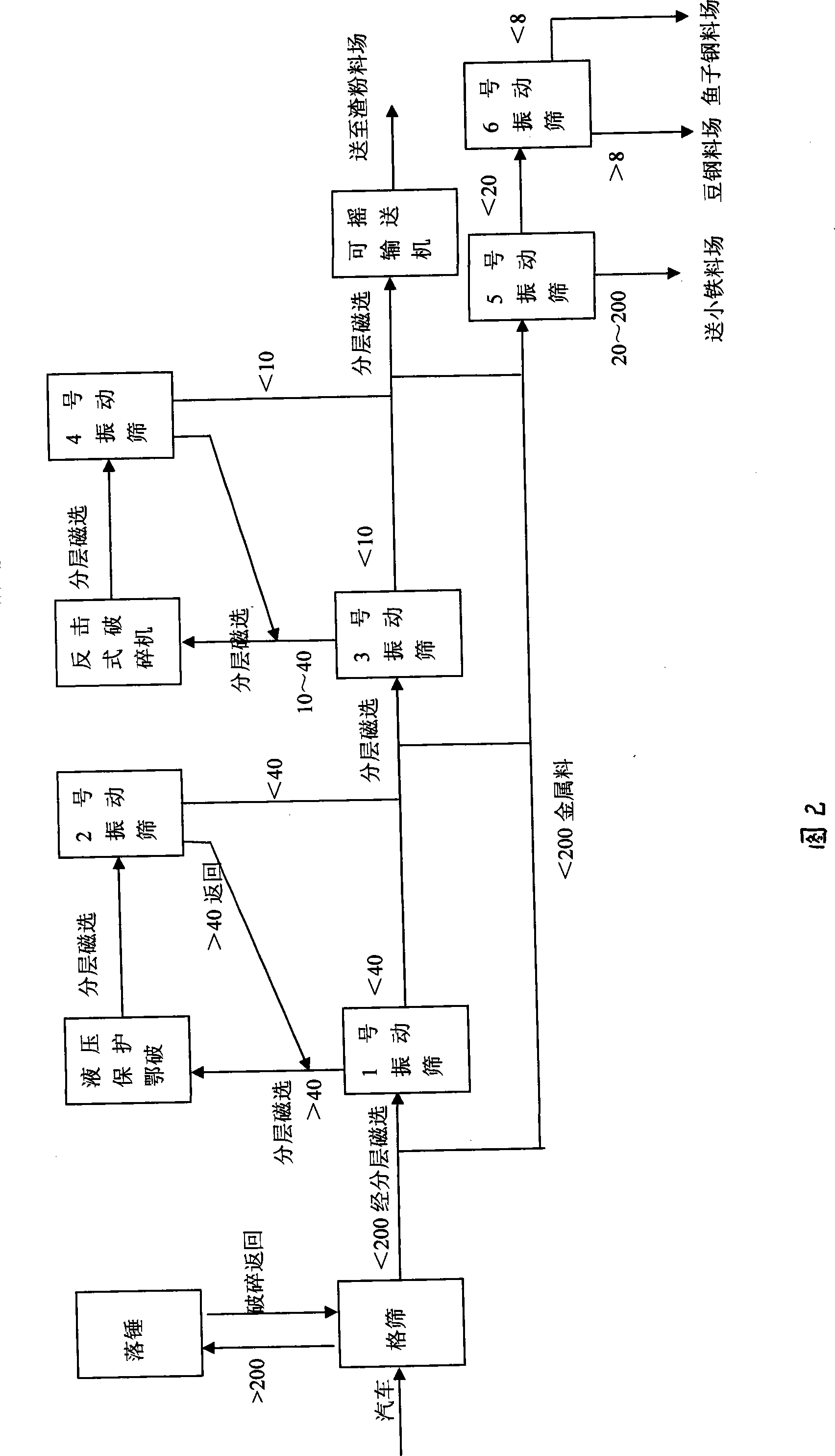

[0021] The steel slag is solidified by hot splashing at the large converter site, and the water content of the steel slag is relatively high, about 8-10%. Post-transport to adopt the present invention for secondary treatment. A method for treating hot-splash solidified steel slag of the present invention comprises the following steps:

[0022] 1. The solidified wet cold steel slag treated by hot splashing is directly poured into the tiltable grid sieve by a dump truck for sieving, and the slag larger than 200mm is recycled back to the grid sieve after being screened and dropped. A hydraulic push rod is installed on the grid sieve bin to automatically control the material door to control the falling speed of the material and make it evenly discharged.

[0023] 2. The slag blocks less than 200mm fall on the conveyor, and the iron content of 260~300mm on the surface is removed by the belt type iron remover, and then the iron content in the lower layer is magnetically separated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com