Application of carbonatation revolving furnace steel scoria in accelerating carbonic anhydride absorption of ocean

A converter steel slag and carbon dioxide technology, applied in the field of environmental protection and resource utilization, can solve problems such as the application of converter steel slag that has not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

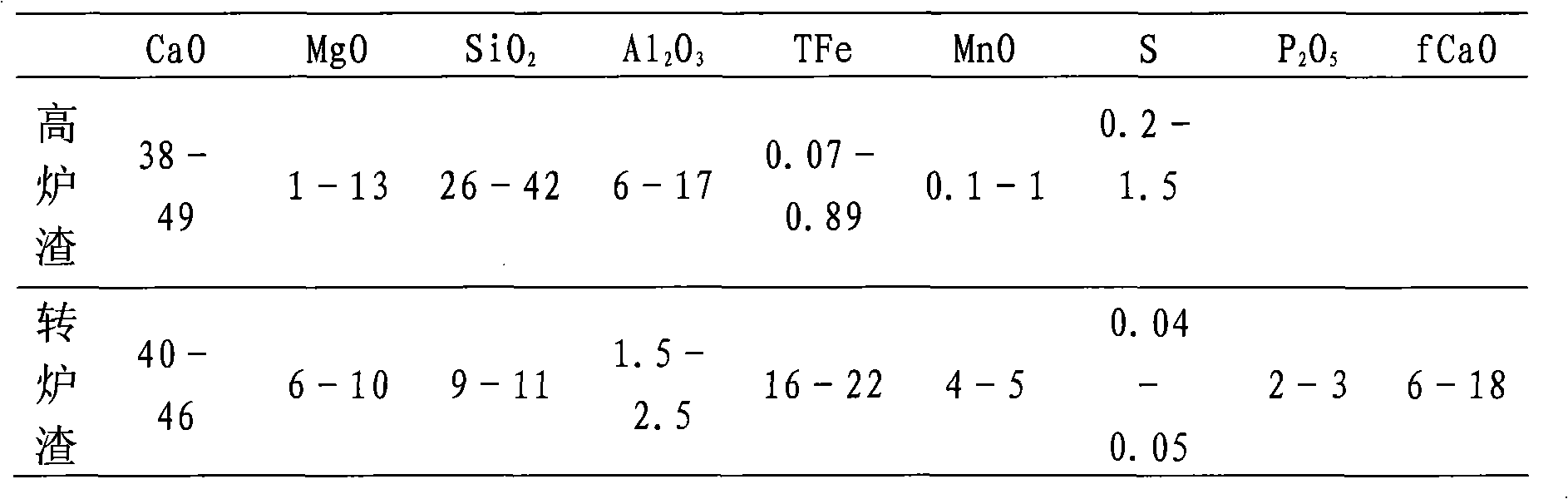

[0039] Chemical composition analysis of blast furnace slag and converter slag of embodiment 1

[0040] The chemical compositions of blast furnace slag and converter slag were compared, and the results are shown in Table 1.

[0041] Table 1 Chemical composition of blast furnace slag and converter steel slag (%)

[0042]

[0043] It can be seen from Table 1 that the main components of blast furnace slag and converter slag are CaO, MgO, Al 2 o 3 , SiO 2 Four kinds, they account for more than 80% of the total weight of slag. The difference is that the iron content in the converter slag is higher, the TFe content reaches 16-22%, and there is more calcium oxide (fCaO) in the free state, and the P 2 o 5 The content of about 2-3%. Iron and phosphorus are essential nutrients for the growth of marine phytoplankton. A large amount of iron can provide a more sufficient nutrient source for marine phytoplankton, and the presence of a large amount of free calcium oxide will increase...

Embodiment 2

[0044] Carbonation treatment of embodiment 2 converter steel slag

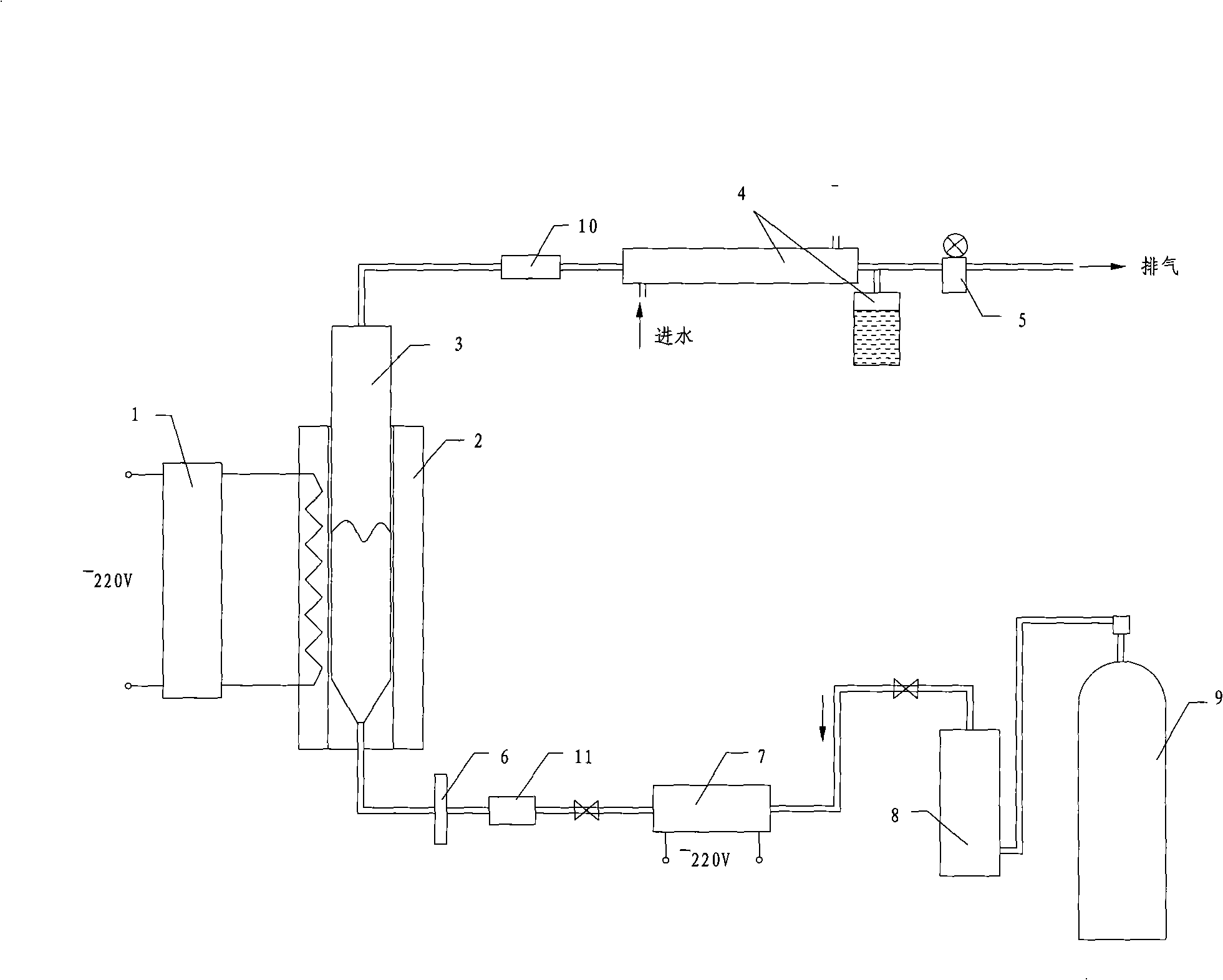

[0045] For carbonation treatment of converter steel slag, see figure 1 . figure 1 Among them, the heating furnace control system 1 and the heating furnace 2 complete the setting and control of the carbonation reaction temperature of the converter steel slag through automatic control; the ebullated bed reactor 3 makes the gas and the converter steel slag mix evenly; the steam condensing device 4 is used for tail gas after reaction Cooling before venting; digital pressure regulator 5 is used for pressure control of tail gas before venting and display and reminder of system pressure safety; flow meter 6 is used for intake flow control; gas heating and supply device 7 pairs enter the ebullated bed reactor The gas is preheated; the regulator 8 is used to control the gas pressure entering the reactor; the gas source 9 is collected industrial waste gas or flue gas, and the laboratory can also use carbon dioxide gas ...

Embodiment 3

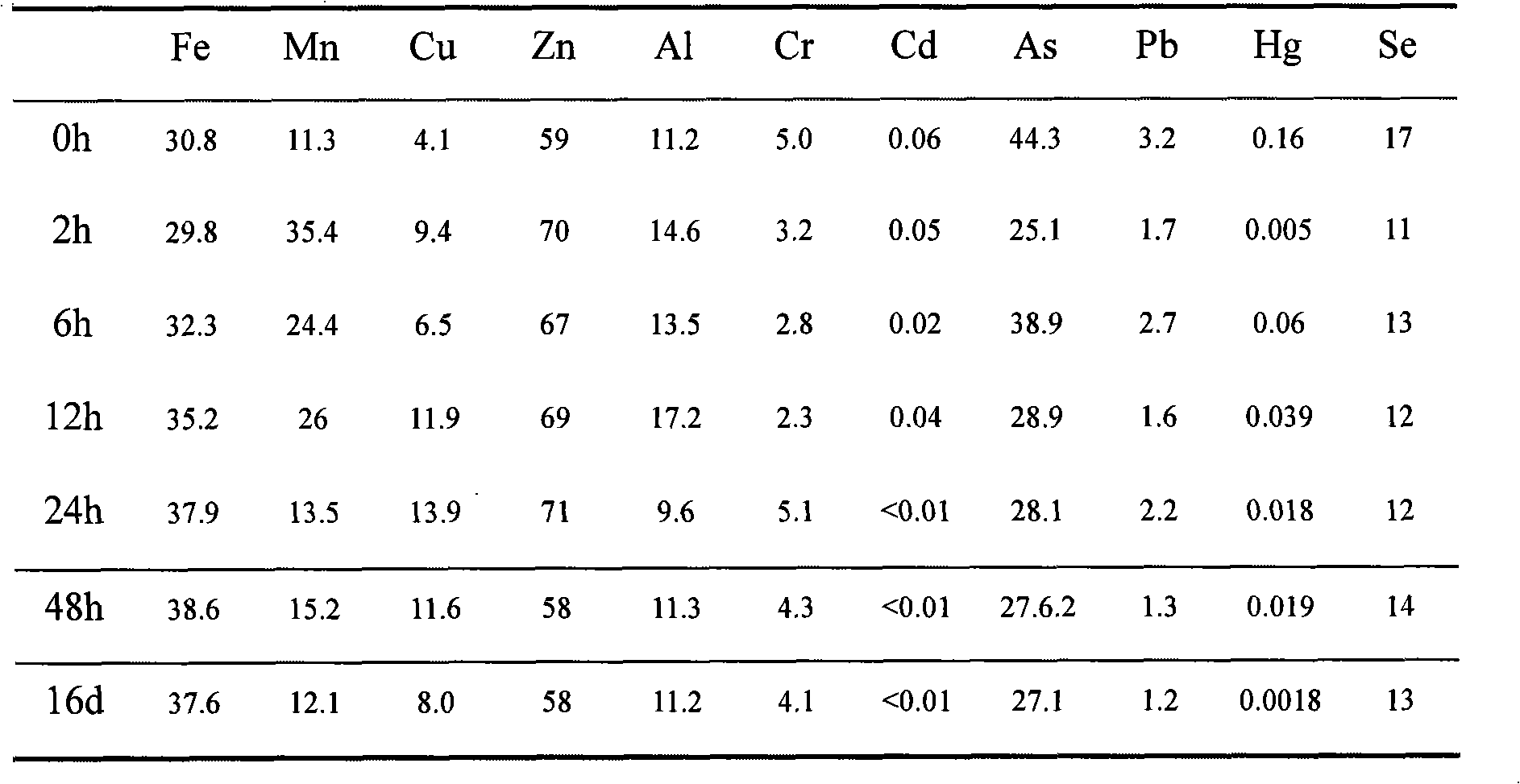

[0047] Example 3 pH value test of converter steel slag seawater eluate

[0048] Place 2 g of untreated converter steel slag and carbonation-treated converter steel slag with a particle size of 75-150 mesh in 0.3 L of seawater taken from the sea, vibrate in a shaker at room temperature, and measure the The pH value of the eluate after the results are shown in Table 2.

[0049] Table 2 Comparison of pH values of seawater eluate between converter steel slag and carbonated converter steel slag

[0050] pH value

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com