Steel scoria mastic detritus asphaltum concrete and method for preparing the same

A kind of asphalt concrete, tellurium resin technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

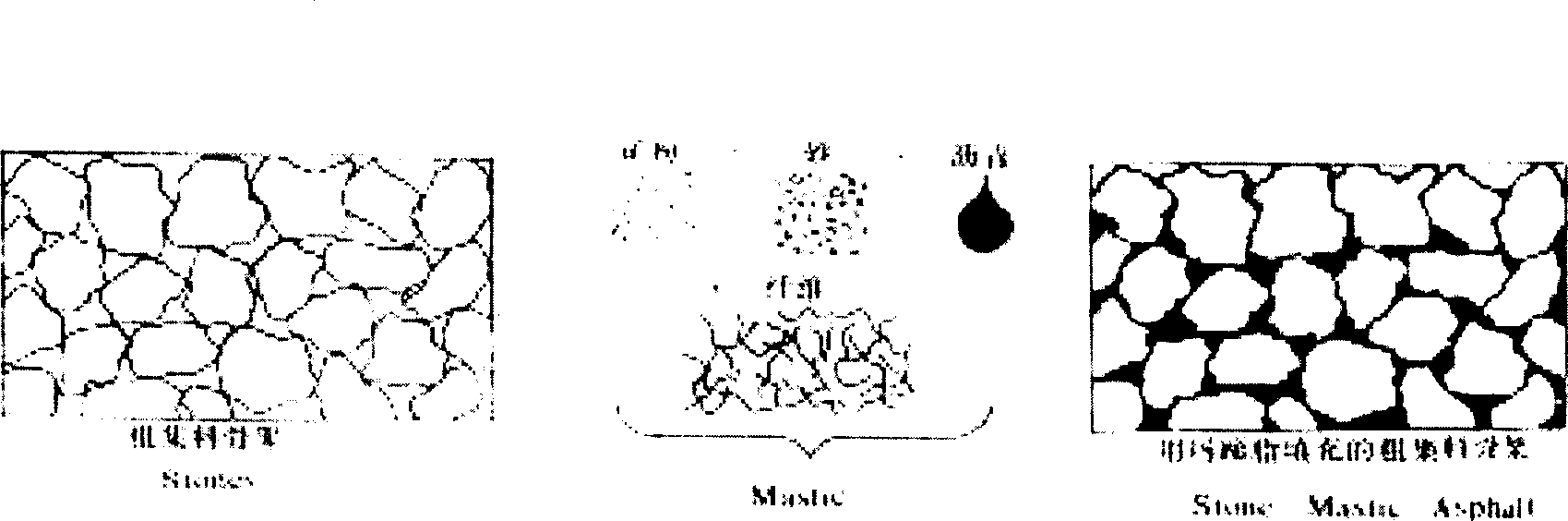

Method used

Image

Examples

Embodiment 1

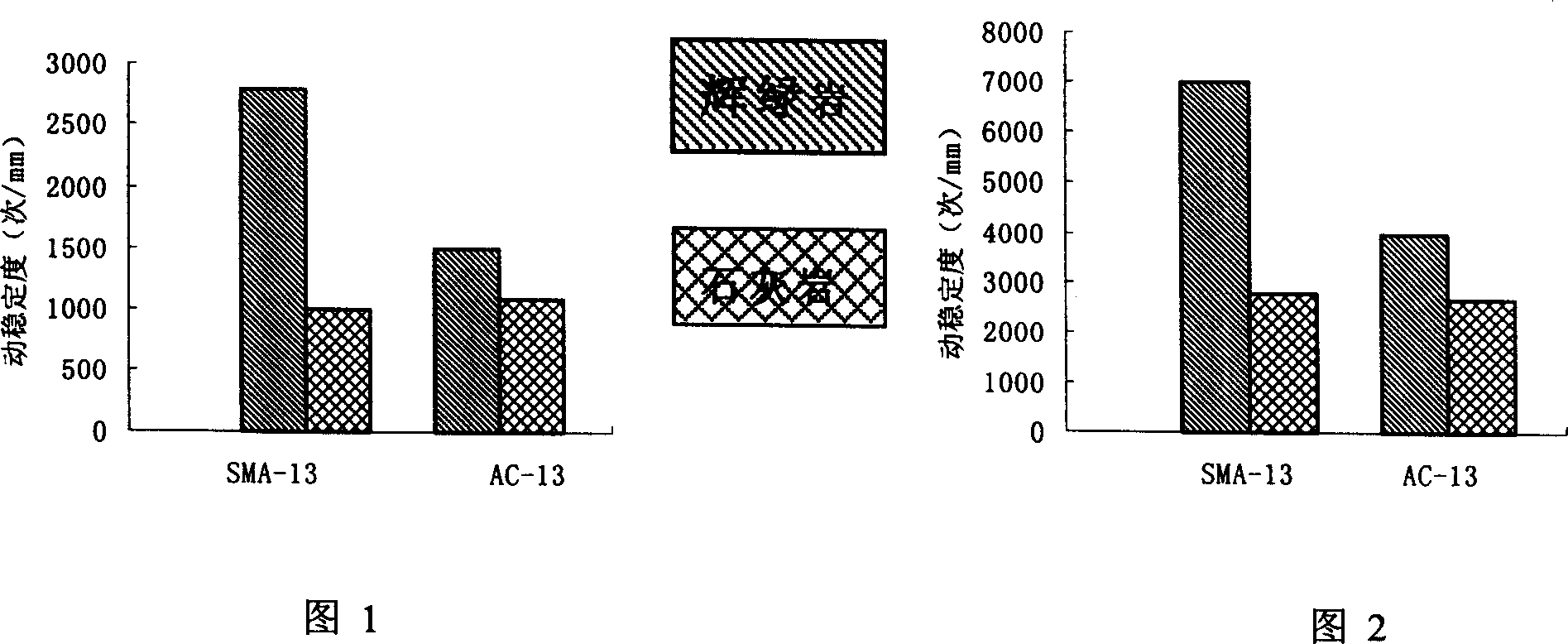

[0031] Steel slag SMA asphalt pavement test. The total length of the test section is 230 meters, and the designed paving width is 6.50 meters. It is divided into middle and upper surface layers. Among them, the upper layer adopts the SMA-13 asphalt mixture proportion.

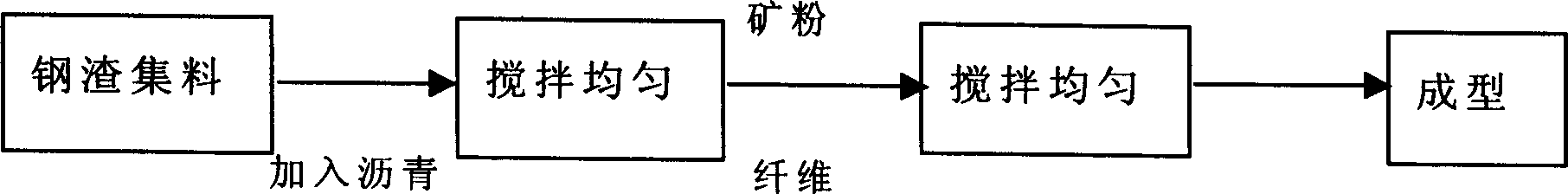

[0032] Raw materials used in SMA-13 asphalt mixture: 1. Aggregate: steel slag 2. Asphalt: SBS modified asphalt 3. Mineral powder: hydrophilic coefficient 0.94, fiber stabilizer: Haichuan Dolanit polyester fiber

[0033] Not SMA-13 steel slag asphalt concrete: 1. Synthetic grading

[0034] Table 1 Synthesis gradation pore size of SMA-13 steel slag asphalt mixture (mm)

[0035] 16 13.2 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.075 synthetic gradation

[0036] 100 95.7 63.3 28.0 20.1 17.0 14.4 12.9 12.1 10.9 (%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com