Extraction and desiccation method in preparing process of polyvinyl fibre with super high molecular weight

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon, fiber processing, rayon cleaning/drying, etc., can solve the problems of easy volatility, equipment corrosion, volatile loss, etc. The effect of low rate, simple process and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

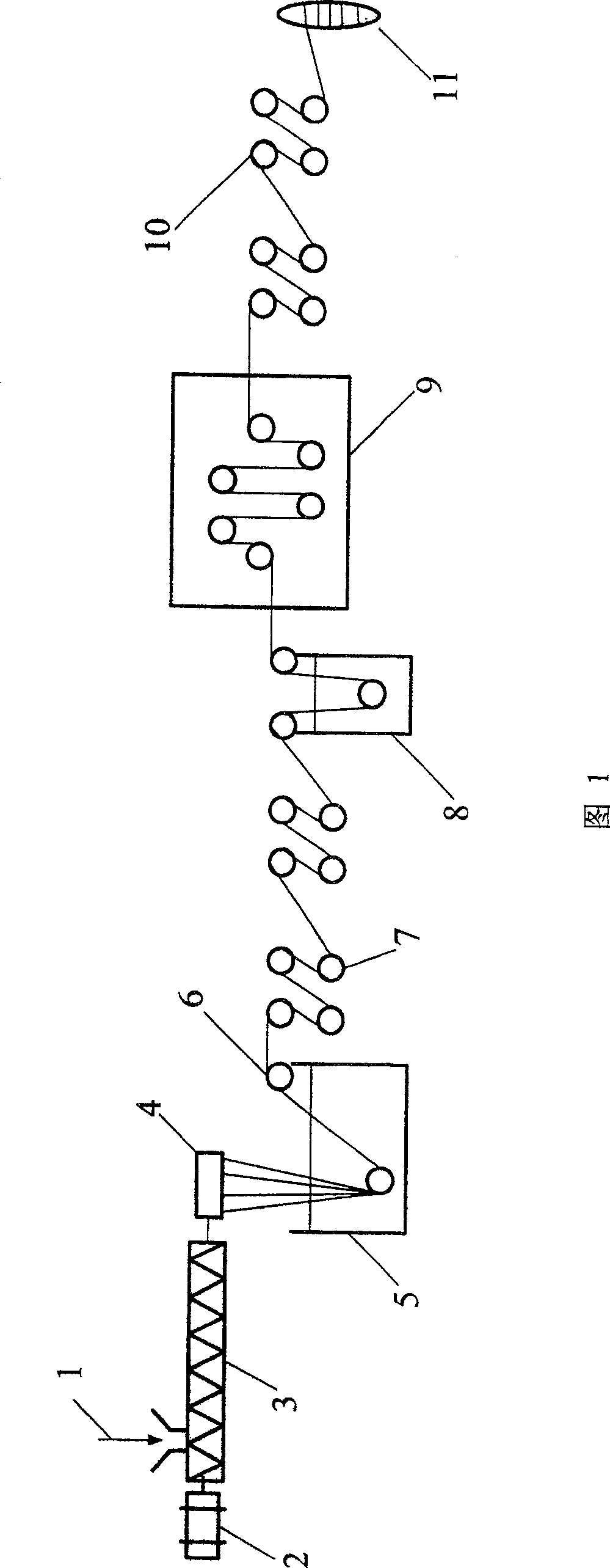

Embodiment 1

[0044] The polyethylene powder with a relative molecular weight of 5 million, additives, and solvent paraffin oil are thoroughly mixed and uniformly dissolved before entering the screw extruder. Then it enters the spinning box, passes through the spinneret, and is extruded into filaments. After cooling in a coagulation water tank, gel fibers are formed and extracted with dichloromethane. The extraction equipment is an extraction tank made of stainless steel. The extraction adopts three-stage countercurrent extraction, and the extraction temperature is 20°C. Water is added to the extraction equipment to form a water seal with a thickness of 5 cm.

[0045] Then enter the drying box for drying treatment, the drying temperature is 35 ℃. The dry gas is air. The dried fibers are hot drawn and then wound into finished products.

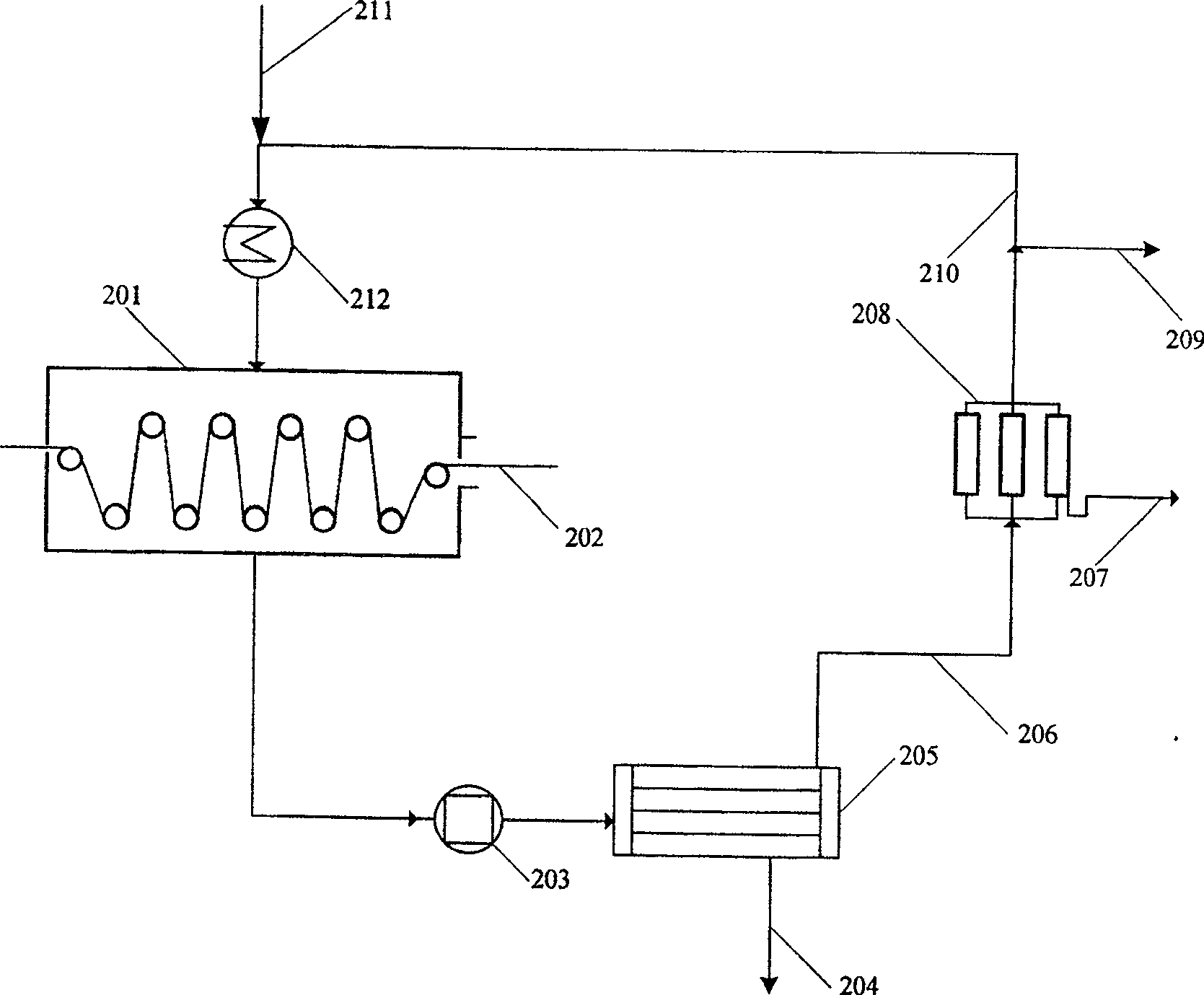

[0046] The dry waste gas is condensed, separated and purified by adsorption for recycling.

[0047] Finally, high-strength and high-modulus ultra-high...

Embodiment 2

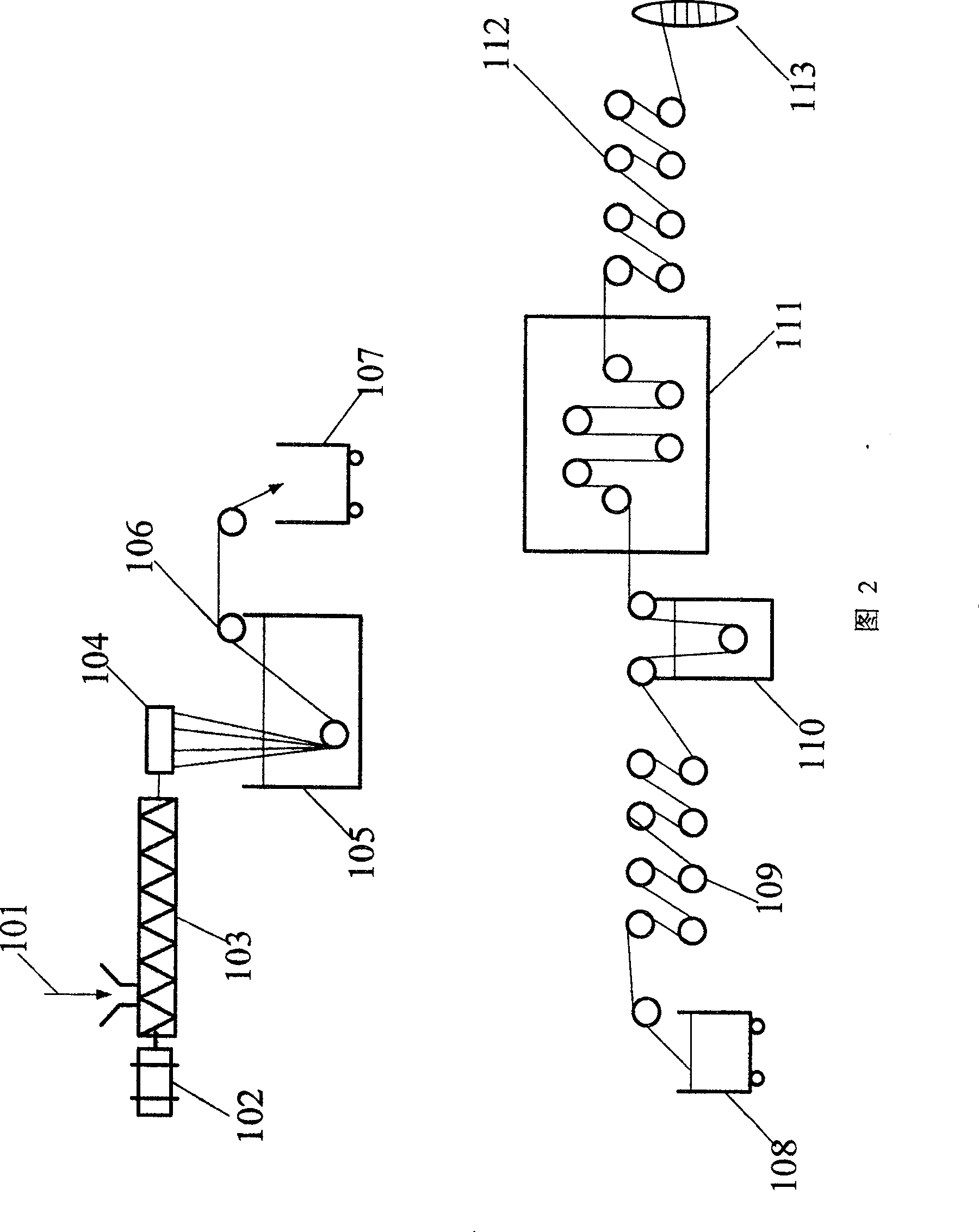

[0049] The polyethylene powder with a relative molecular weight of 5 million, additives, and solvent paraffin oil are thoroughly mixed and uniformly dissolved, and then extruded into filaments by a screw extruder through a spinneret. After cooling in a coagulation water tank, gel fibers are formed and extracted with dichloromethane. The extraction equipment is a ceramic extraction box, which adopts one-stage countercurrent extraction, and the extraction temperature is 5°C. Then enter the drying oven for drying treatment at a drying temperature of 10°C. The dry gas is air. The dried fibers are hot drawn and then wound into finished products.

[0050] Add water to the extraction tank to form a water seal with a thickness of 1 cm.

[0051] The dry exhaust gas is separated and purified by adsorption, and some fresh air is supplemented and then enters the drying box for recycling.

[0052] Finally, high-strength and high-modulus ultra-high molecular weight polyethylene fibers a...

Embodiment 3

[0054] The polyethylene powder with a relative molecular weight of 5 million, additives, and solvent paraffin oil are thoroughly mixed and uniformly dissolved, and then extruded into filaments by a screw extruder through a spinneret. After cooling in a coagulation water tank, gel fibers are formed and extracted with dichloromethane. The extraction equipment is an extraction tank made of polytetrafluoroethylene, which adopts countercurrent secondary extraction, and the extraction temperature is 10°C. Then enter the drying box for drying treatment, the drying temperature is 25 ℃. The drying gas was nitrogen. The dried fibers are hot drawn and then wound into finished products.

[0055] Add water to the extraction tank to form a water seal with a thickness of at least 5 cm.

[0056] After the dry waste gas is purified by membrane separation, some fresh air is supplemented and then enters the drying box for recycling.

[0057] Finally, high-strength and high-modulus ultra-high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com