Liquid blast furnace slag granulation device and granulation method thereof

A blast furnace slag, liquid technology, applied in the field of blast furnace slag utilization, can solve the problems of high power consumption, increased maintenance costs, high investment and operating costs, and achieve energy and water resource conservation, enhanced crushing effects, and low water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific structure, working principle and implementation of the device will be described in detail below in conjunction with the accompanying drawings.

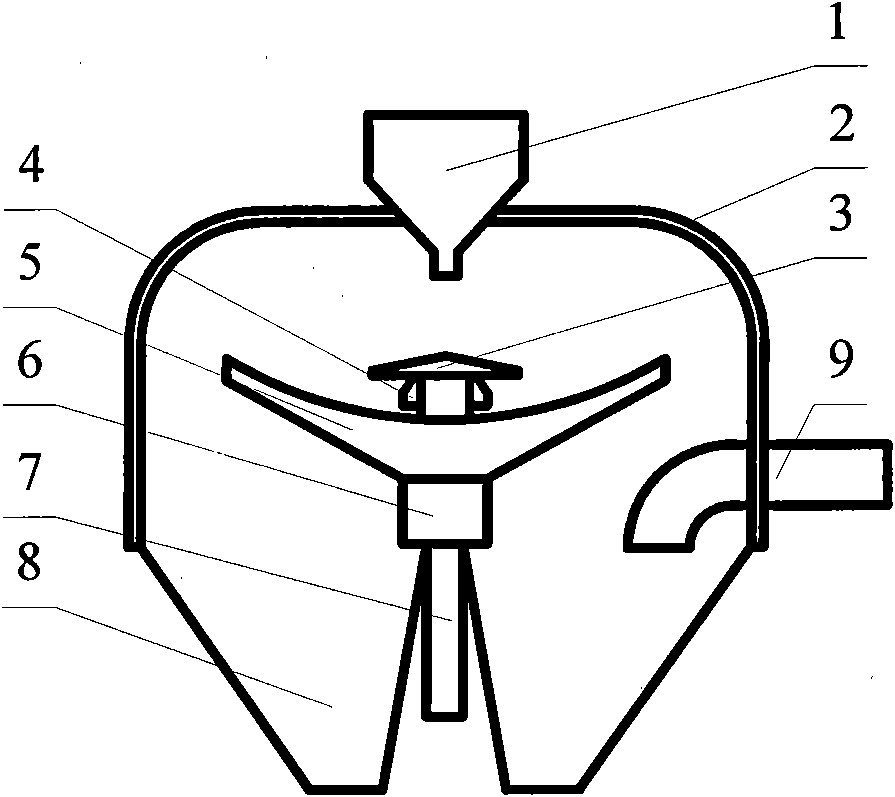

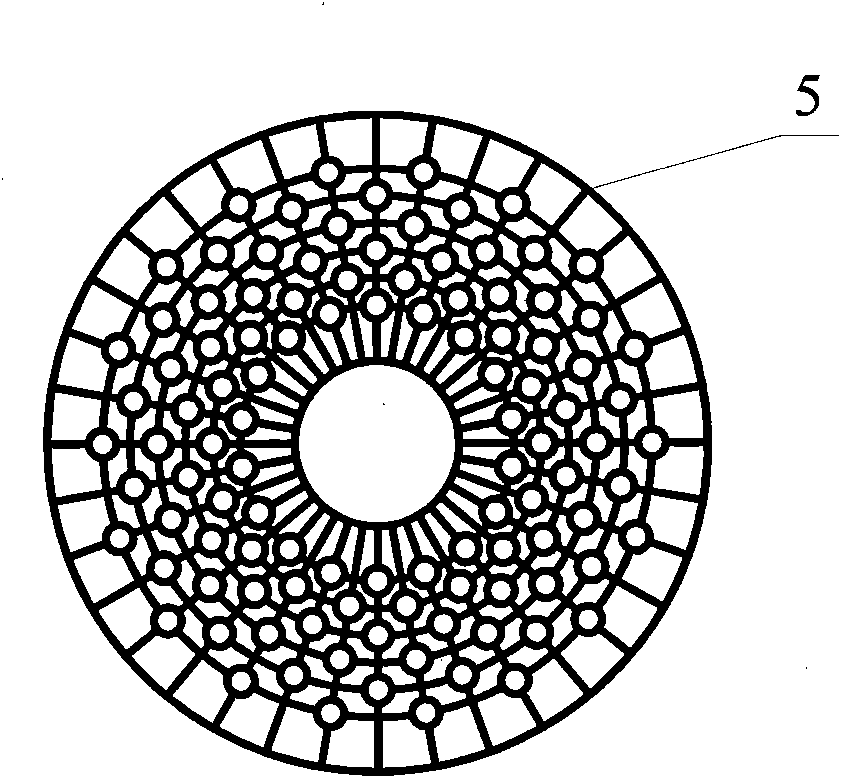

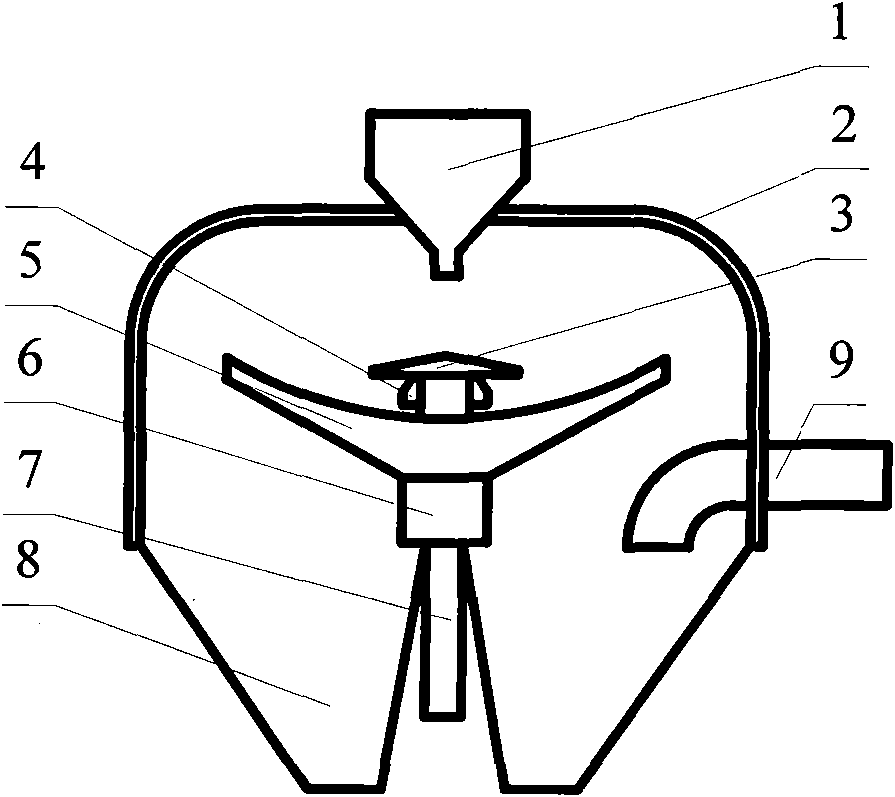

[0022] Such as figure 1 As shown, the liquid blast furnace slag granulation device includes a gate 1, a granulator 2, a primary turntable 3, a water nozzle 4, a secondary turntable 5, a driving device 6, a central water delivery pipe 7, a slag hopper 8, and an exhaust pipe 9 .

[0023] The gate 1 is arranged in the middle part of the upper end of the granulator 2, with the centerline of the granulator 2 as the center line, and the lower end of the gate 1 passes through the upper part of the granulator 2 and is inserted into the granulator 2 . The granulator 2 is the main body of the entire liquid blast furnace slag granulation device, the upper half of which adopts a water-cooled wall structure, and the lower half shrinks to form a slag hopper 8 . The primary turntable 3, water nozzle 4, secondary turntable 5, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com