Full-width vacuum water suctioning device for knitting

A vacuum water absorption and open width technology, which is applied in the direction of liquid/gas/vapor removal by suction method, can solve the problems of increasing the dimensional instability of the fabric, reducing the process speed, affecting the effect of alkali removal, etc., to shorten the water absorption time, The effect of increasing the contact area and improving the water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

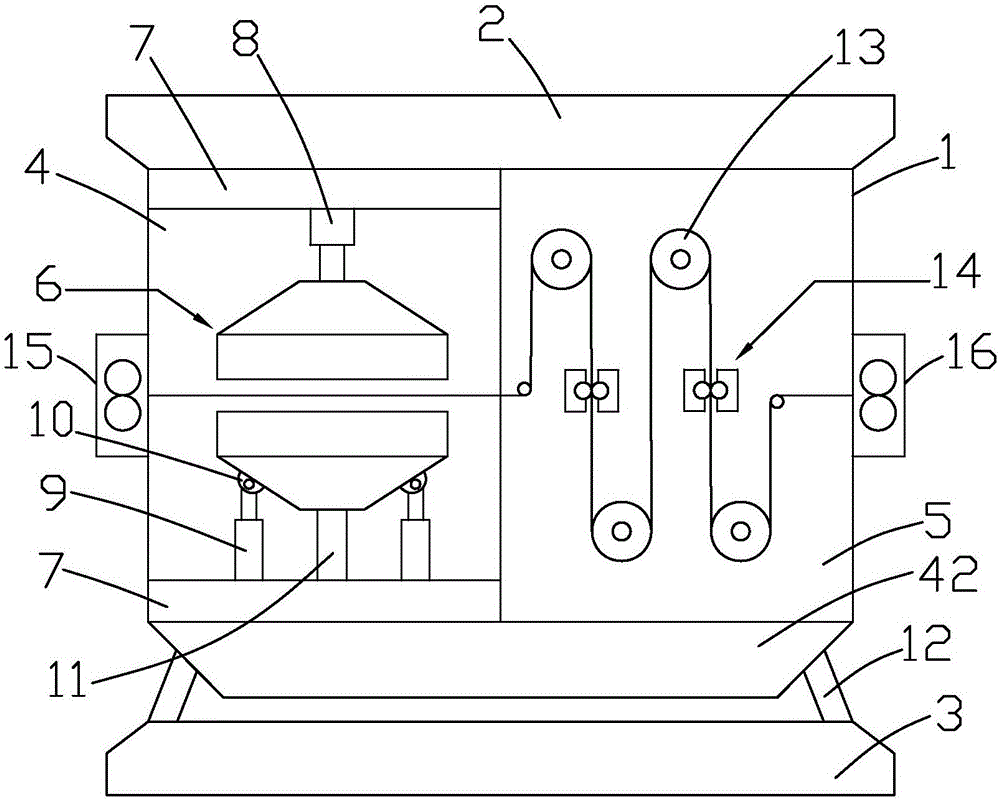

[0030] Such as Figure 1 to Figure 6As shown, it is a vacuum suction device for knitted open width of the present invention, comprising a box body 1, the left and right sides of the box body 1 are respectively provided with a feed port 15 and a discharge port 16, and the upper and lower sides of the box body 1 are respectively provided with The upper mounting plate 2 and the lower mounting plate 3, the lower mounting plate 3 is fixedly connected on the supporting plate 42 through the support rod 12, the feeding port 15 and the feeding port 16 are convenient for the fabric to enter and exit, improve the water absorption effect, shorten the water absorption time, and the upper installation The plate 2 and the lower mounting plate 3 are used to fixedly connect the vacuum water absorbing device to the open width knitting machine, which is convenient for disassembly and installation. The support rod 12 improves the stability of the vacuum water absorbing device during installation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com