Yarn washing and drying machine

A dryer and yarn technology, applied in textile and papermaking, liquid/gas/vapor textile processing, liquid/gas/vapor removal by suction, etc., can solve the problem of low work efficiency, slow yarn drying speed, etc. problems, to achieve the effect of improving work efficiency, staff relaxation, and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

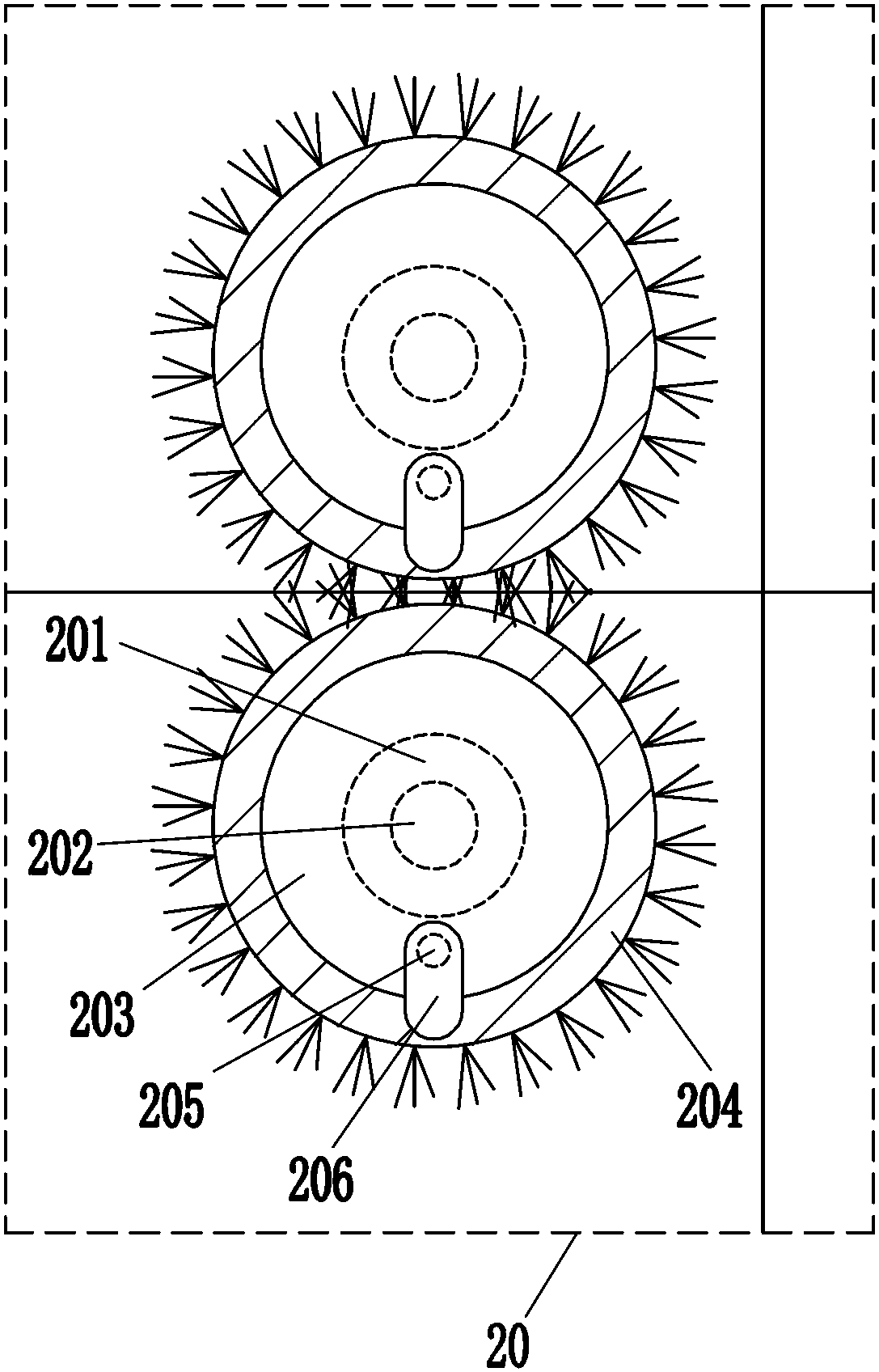

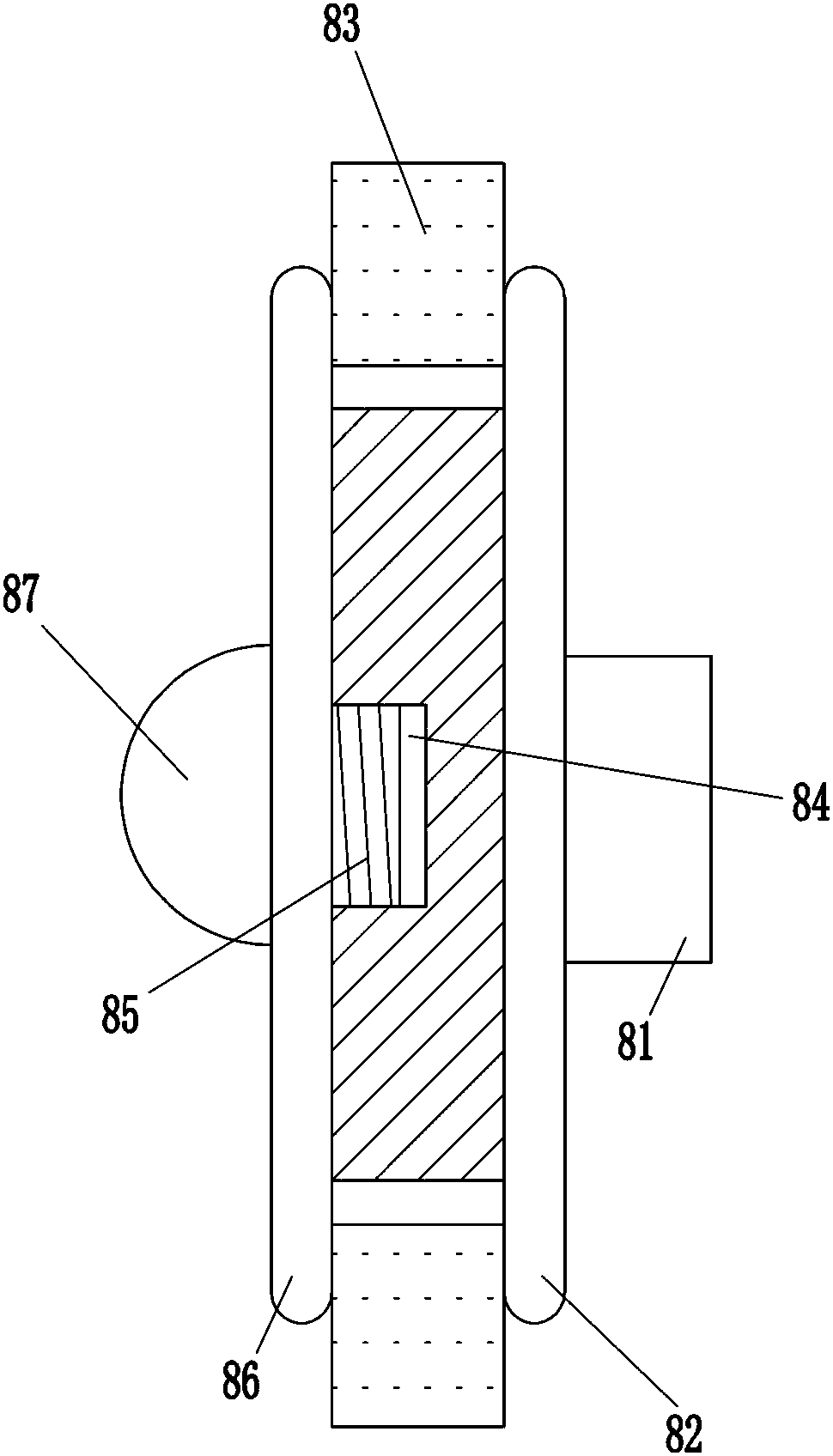

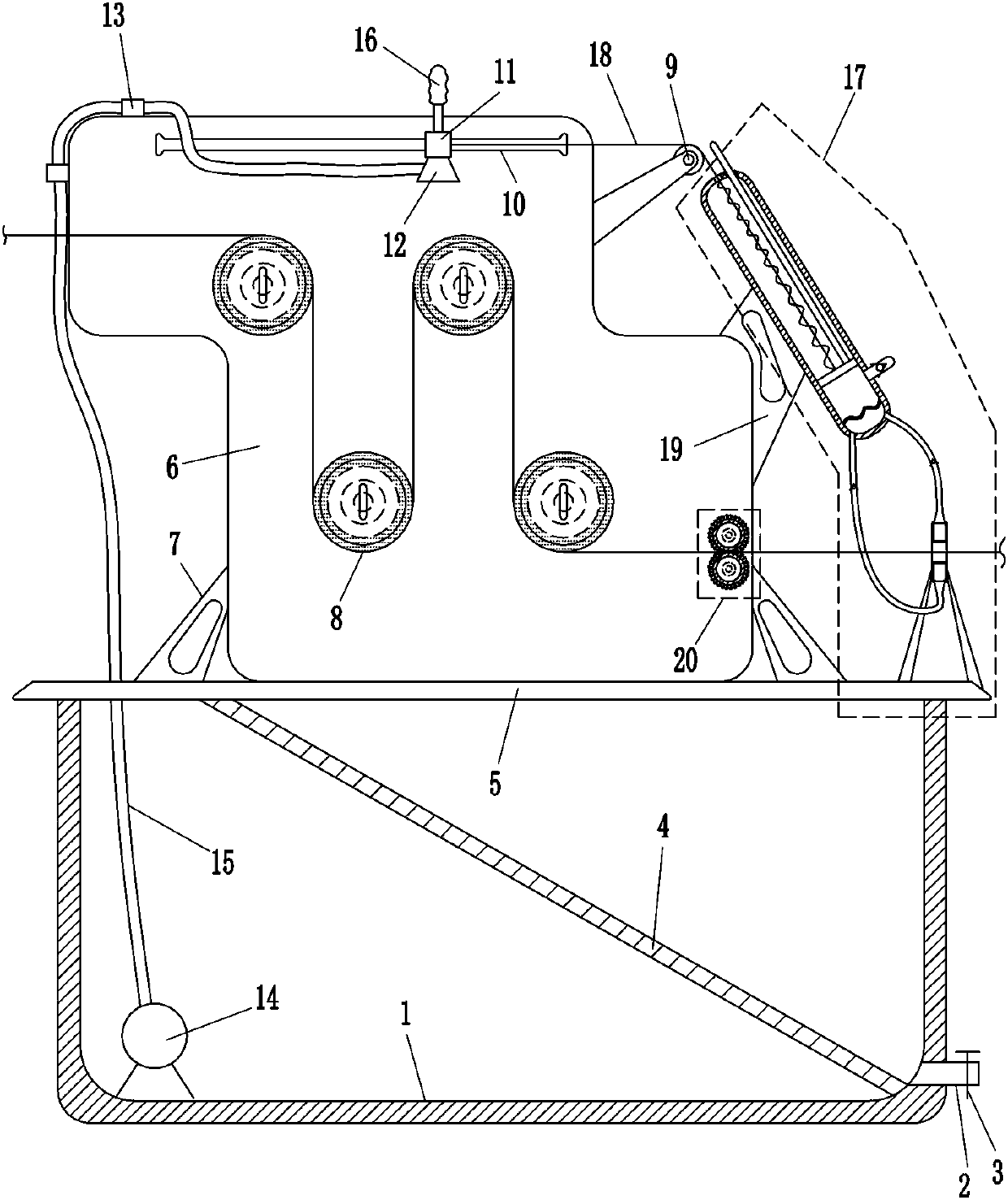

[0018] A yarn washing and drying machine such as Figure 1-3 As shown, it includes a water frame 1, an outlet pipe 2, a valve 3, a partition plate 4, a mounting plate 5, a vertical plate 6, a support plate 7, a cleaning device 8, a first pulley 9, a slide rail 10, a slider 11, Nozzle 12, guide sleeve 13, water pump 14, hose 15, push handle 16, drying device 17, first pull wire 18 and support plate 19, the water outlet pipe 2 that is used to discharge dirty water is connected with the lower part of the right side of water frame 1, outlet The water pipe 2 is provided with a valve 3, and the right side of the inner bottom of the water frame 1 is connected with a partition plate 4 obliquely. The mounting plate 5 is connected with the water frame 1 by means of bolt connection, the bottom of the mounting plate 5 is connected with the top of the partition plate 4, and the middle of the top of the mounting plate 5 is bolted with a supporting vertical plate 6, and there are two support...

Embodiment 2

[0020] A yarn washing and drying machine such as Figure 1-3 As shown, it includes a water frame 1, an outlet pipe 2, a valve 3, a partition plate 4, a mounting plate 5, a vertical plate 6, a support plate 7, a cleaning device 8, a first pulley 9, a slide rail 10, a slider 11, Nozzle 12, guide sleeve 13, water pump 14, hose 15, push handle 16, drying device 17, first pull wire 18 and support plate 19, the water outlet pipe 2 that is used to discharge dirty water is connected with the lower part of the right side of water frame 1, outlet The water pipe 2 is provided with a valve 3, and the right side of the inner bottom of the water frame 1 is connected with a partition plate 4 obliquely. The bottom of the mounting plate 5 is connected to the top of the partition plate 4, and the middle of the mounting plate 5 top is bolted with a supporting vertical plate 6. There are two support plates 7, which are respectively located on the left and right sides of the top of the mounting pl...

Embodiment 3

[0023] A yarn washing and drying machine such as Figure 1-3As shown, it includes a water frame 1, an outlet pipe 2, a valve 3, a partition plate 4, a mounting plate 5, a vertical plate 6, a support plate 7, a cleaning device 8, a first pulley 9, a slide rail 10, a slider 11, Nozzle 12, guide sleeve 13, water pump 14, hose 15, push handle 16, drying device 17, first pull wire 18 and support plate 19, the water outlet pipe 2 that is used to discharge dirty water is connected with the lower part of the right side of water frame 1, outlet The water pipe 2 is provided with a valve 3, and the right side of the inner bottom of the water frame 1 is connected with a partition plate 4 obliquely. The bottom of the mounting plate 5 is connected to the top of the partition plate 4, and the middle of the mounting plate 5 top is bolted with a supporting vertical plate 6. There are two support plates 7, which are respectively located on the left and right sides of the top of the mounting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com