Rapid cloth cleaning equipment for textile processing

A kind of cleaning equipment and fast technology, applied in the direction of textile processing machine accessories, textile material cleaning device, textile material treatment, etc., can solve the problems of high heat consumption, improper rubbing force, cloth damage, etc., and achieve good drying effect and clean Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

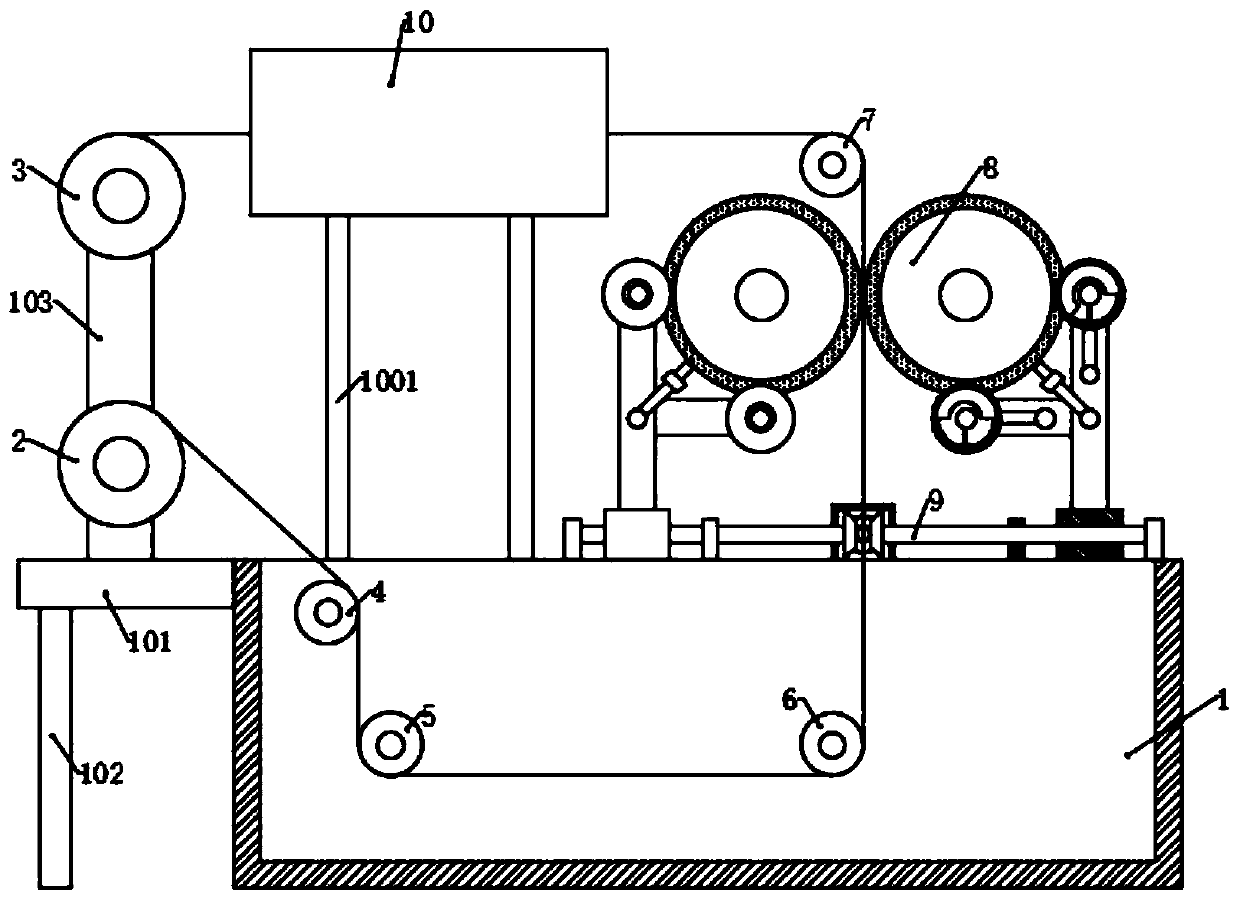

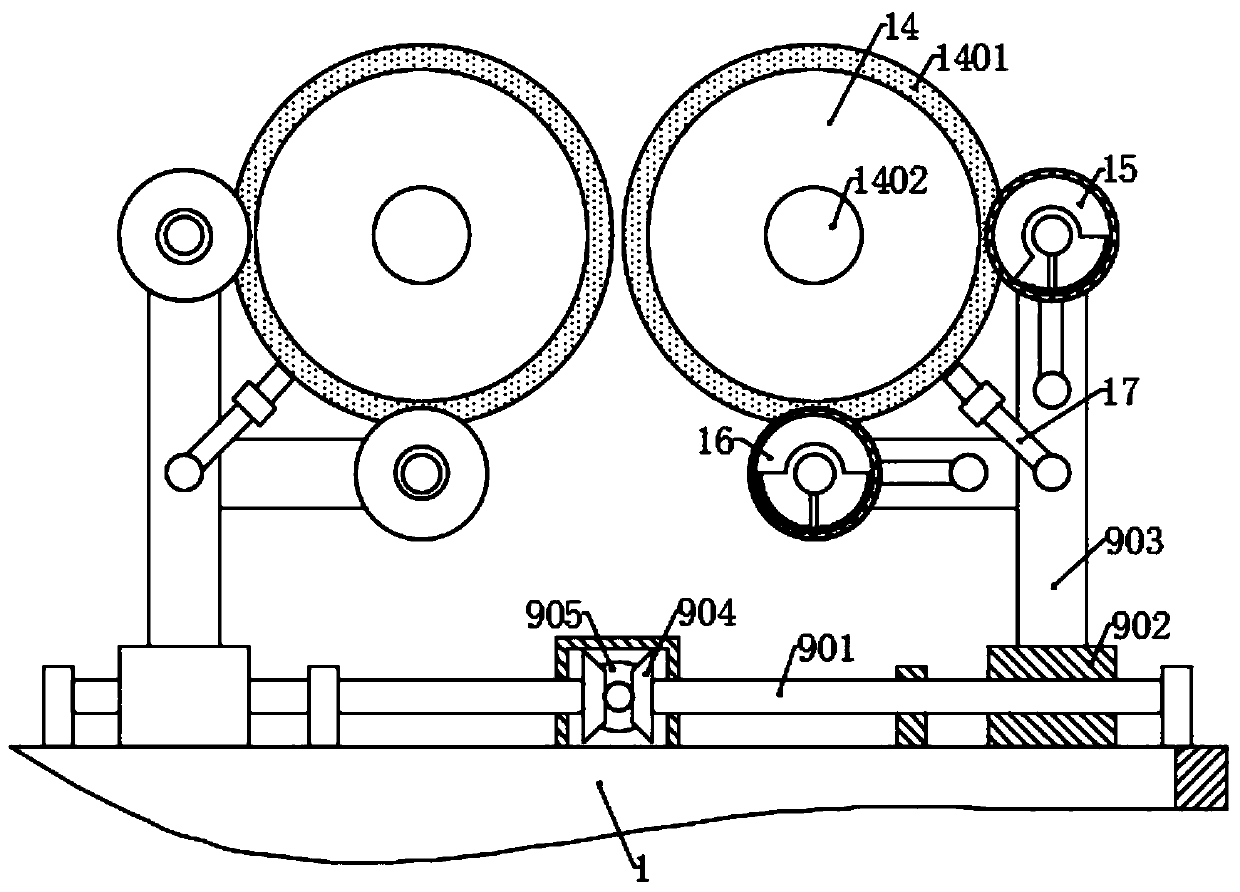

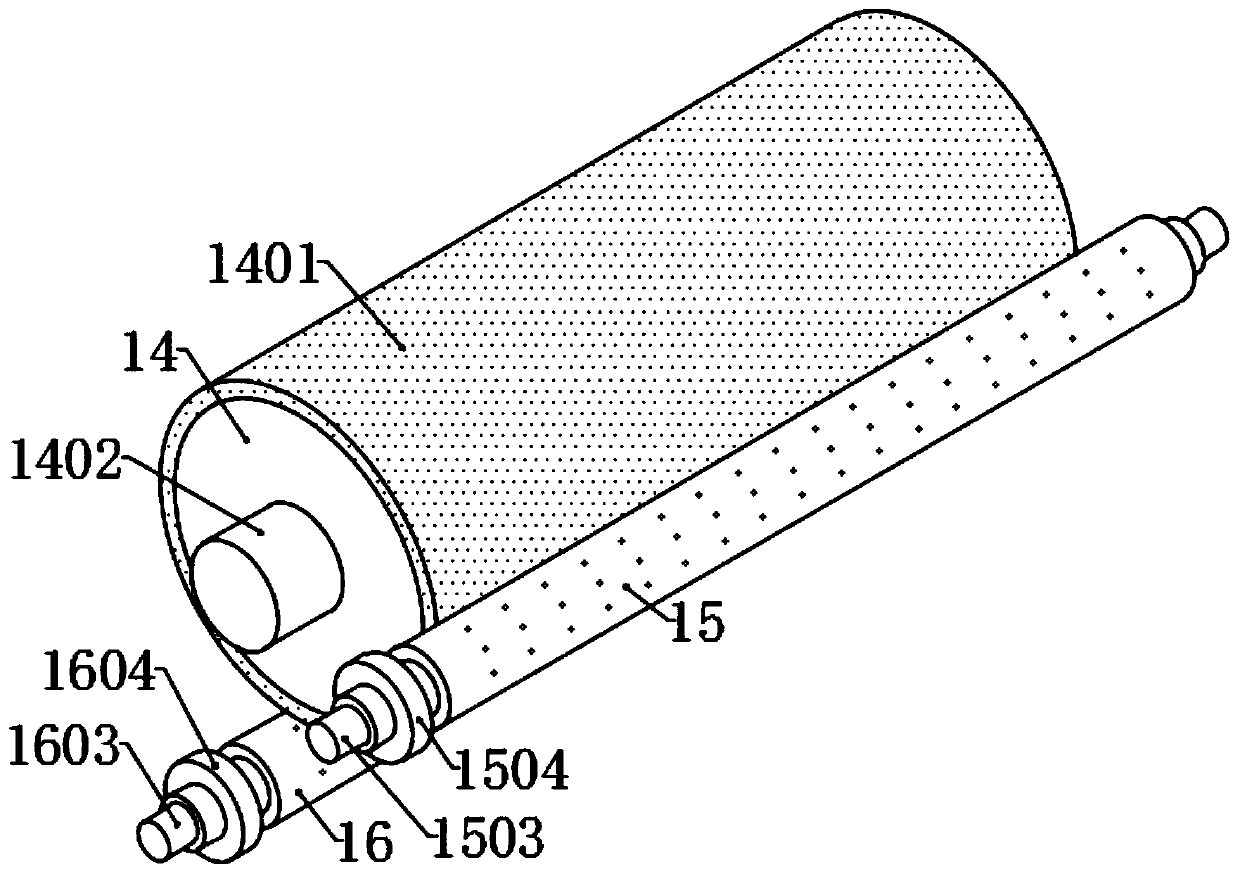

[0044] Please refer to the accompanying drawings, the present invention provides a technical solution: a rapid cleaning equipment for textile processing cloth, including a cleaning tank 1, a feeding cylinder 2, a material receiving cylinder 3, a drying mechanism 8, a drying mechanism 10 and an adjusting mechanism 9 , the left side of the cleaning tank 1 is fixed with a fixed plate 1305101, the bottom surface of the fixed plate 1305101 is fixed with a support leg 102, and the top surface is fixed with a fixed frame 103. The lower part and the upper part of the frame 103, and the material receiving cylinder 3 is connected with a material receiving motor, the upper left part of the cleaning tank 1 is rotatably connected with the first guide wheel 4, and the lower right side of the first guide wheel 4 is rotatably connected with a The second guide wheel 5 and the third guide wheel 6, the drying mechanism 8 is located above the third guide wheel 6, and the top of both side walls of ...

Embodiment 2

[0052] On the basis of Embodiment 1, a cleaning mechanism 11 is also included, and the cleaning mechanism 11 includes two connecting plates 1104 arranged symmetrically, and two parallel fixed cylinders 1101 are arranged between the bottoms of the two connecting plates 1104, A rotating shaft 1105 is fixed on the upper part of the connecting plate 1104 , and one end of the rotating shaft 1105 passes through the side wall of the cleaning tank 1 and is connected with the swing mechanism 13 .

[0053] The middle of the fixed cylinder 1101 is rotatably connected with a connecting shaft 1102, and the connecting shaft 1102 is fixedly connected with one of the connecting plates 1104. A plurality of rotating grooves are evenly arranged on the side of the fixing cylinder 1101 along the circumferential direction, and the rotating grooves A roller 1103 is arranged in the middle, and a part of the side of the roller 1103 is exposed in the rotating groove. Both ends of the fixed cylinder 1101...

Embodiment 3

[0057] On the basis of the second embodiment, it also includes two water spray pipes 12, the two water spray pipes 12 are symmetrically arranged above the third guide wheel 6, and the two water spray pipes 12 are connected with the same water pump, and the two water spray pipes 12 are connected with the same water pump. One side of the cleaning tank 1 is provided with a water tank, and the water pump is located in the water tank.

[0058] When the cloth moves vertically to the water surface of the cleaning tank 1 through the action of the third guide wheel 6 and the fourth guide wheel 7, the cloth is rinsed again through the water spray pipe 12 to avoid the floating dust on the surface of the water layer from adhering to Problems such as incomplete cleaning caused by the surface of the cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com