Drying process during viscose production

A technology of viscose fiber and technology, which is applied in the field of viscose fiber production technology, and can solve problems such as inability to improve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

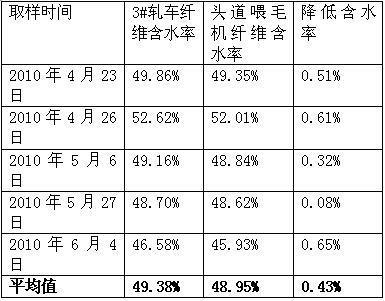

Examples

Embodiment 1

[0020] A. Feed the fibers refined by the refining machine into the wet opener for wet opening, and then enter the cotton collecting box of the wet opener;

[0021] B. Heat the waste hot air with a temperature of 40°C and a humidity of 45% of the rotary screen dryer through the heater to form hot and humid air with a temperature of 55°C and a humidity of 30%, and then enter the cotton collection box and the cotton collection box The fibers are sent to the separator through the fan; the heater is heated by the waste heat of the water drained from the drying trap;

[0022] C. During the above process, the hot air absorbs moisture, and the fiber is separated from the hot and humid air in the separator, and then it enters the first wool feeder and then is dried with a dryer, and the waste heat air of the dryer enters the heater in step B.

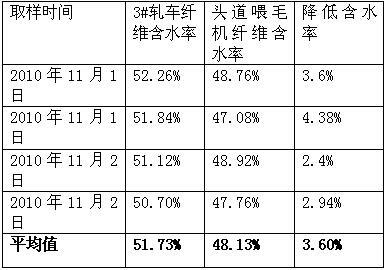

Embodiment 2

[0024] A. Feed the fibers refined by the refining machine into the wet opener for wet opening, and then enter the cotton collecting box of the wet opener;

[0025] B. Heat the waste hot air with a temperature of 50°C and a humidity of 50% of the rotary screen dryer through the heater to form hot and humid air with a temperature of 65°C and a humidity of 40%, and enter the cotton collection box and the cotton collection box The fibers are sent to the separator through the fan; the heater is heated by the waste heat of the water drained from the drying trap;

[0026] C. During the above process, the hot air absorbs moisture, and the fiber is separated from the hot and humid air in the separator, and then it enters the first wool feeder and then is dried with a dryer, and the waste heat air of the dryer enters the heater in step B.

Embodiment 3

[0028] A. Feed the fibers refined by the refining machine into the wet opener for wet opening, and then enter the cotton collecting box of the wet opener;

[0029] B. Heat the waste hot air with a temperature of 45°C and a humidity of 46% of the rotary screen dryer through the heater to form hot and humid air with a temperature of 60°C and a humidity of 35%, and enter the cotton collection box and the cotton collection box The fibers are sent to the separator through the fan; the heater is heated by the waste heat of the water drained from the drying trap;

[0030] C. During the above process, the hot air absorbs moisture, and the fiber is separated from the hot and humid air in the separator, and then it enters the first wool feeder and then is dried with a dryer, and the waste heat air of the dryer enters the heater in step B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com