Method for spraying wet steaming and dyeing cotton fabric by using reactive dye

A technology for reactive dyes and cotton fabrics, applied in the field of fabric dyeing process and fabric wet steam dyeing process, can solve the problems of difficult process control, difficult operation, high production cost, overcome the harsh requirements of dyeing equipment and processes, and accelerate the temperature rise. speed, maintain a stable and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

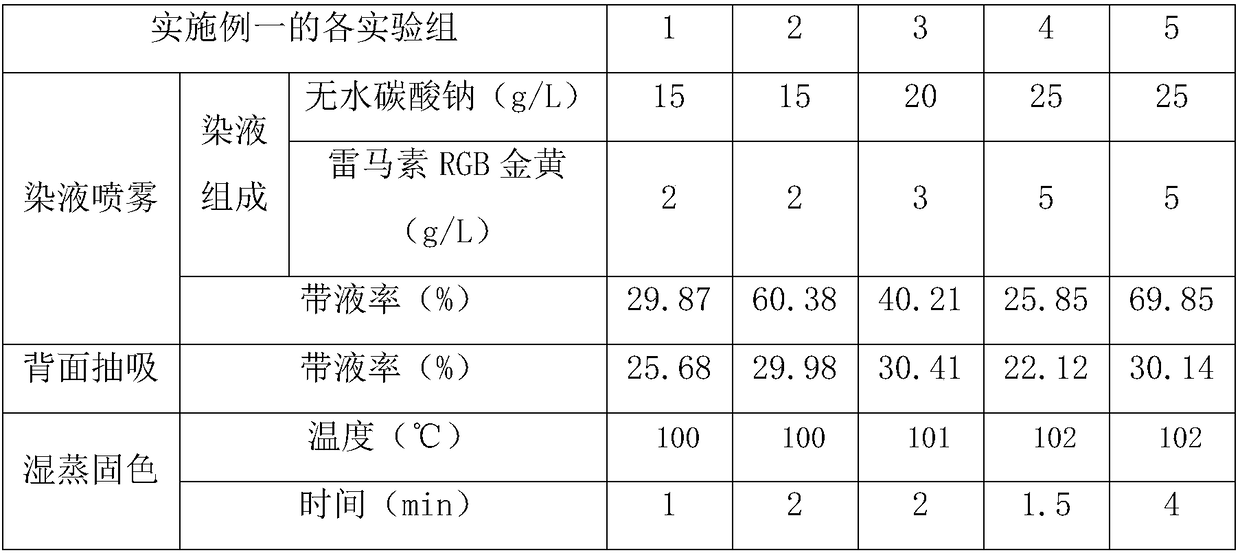

Embodiment 1

[0022] In this embodiment, the raw materials used in each experimental group, the reactive dyes are commercially available products from DyStar (Shanghai) Trading Co., Ltd., and the rest of the raw materials are all commercially available products.

[0023] A kind of reactive dye adopts the method for spraying wet steam dyeing to cotton fabric, and concrete operation steps are as follows:

[0024] (1) Dye liquor spray: prepare dye liquor containing color fixing agent, spray it into the atomization box through the atomization device at room temperature, transport the fabric to the atomization box to accept the color mist, and apply the color mist to the On the fabric cloth, the spray amount is controlled by adjusting the atomized liquid and the compressed air flow; in the process of spraying the dye liquor, according to the comparison between the sprayed atomized liquid quality and the fabric quality, the applied amount of the sprayed atomized liquid It is 25.85-69.85wt.% of th...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, especially in that:

[0043] In this embodiment, by adjusting any one of the process conditions or any combination of several process conditions in the formulation of the atomized liquid containing the fixing agent and the dye, the spray volume, the size of the droplets, and the strength of the suction wind, the fabric can be processed. Any one of three different dyeing processes in one-sided coloring, positive and negative yin-yang coloring, and positive and negative coloring of the same color. The method of this embodiment can obtain cotton fabrics with different dyeing effects by adjusting the dyeing process, and can obtain single-sided coloring and positive dyeing by adjusting the dye solution formula, spray volume, droplet size and suction wind intensity containing the fixing agent. There are three different dyeing effects of yin and yang colors on the reverse side and the same color on the front and back sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com