Patents

Literature

72results about How to "Low moisture regain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

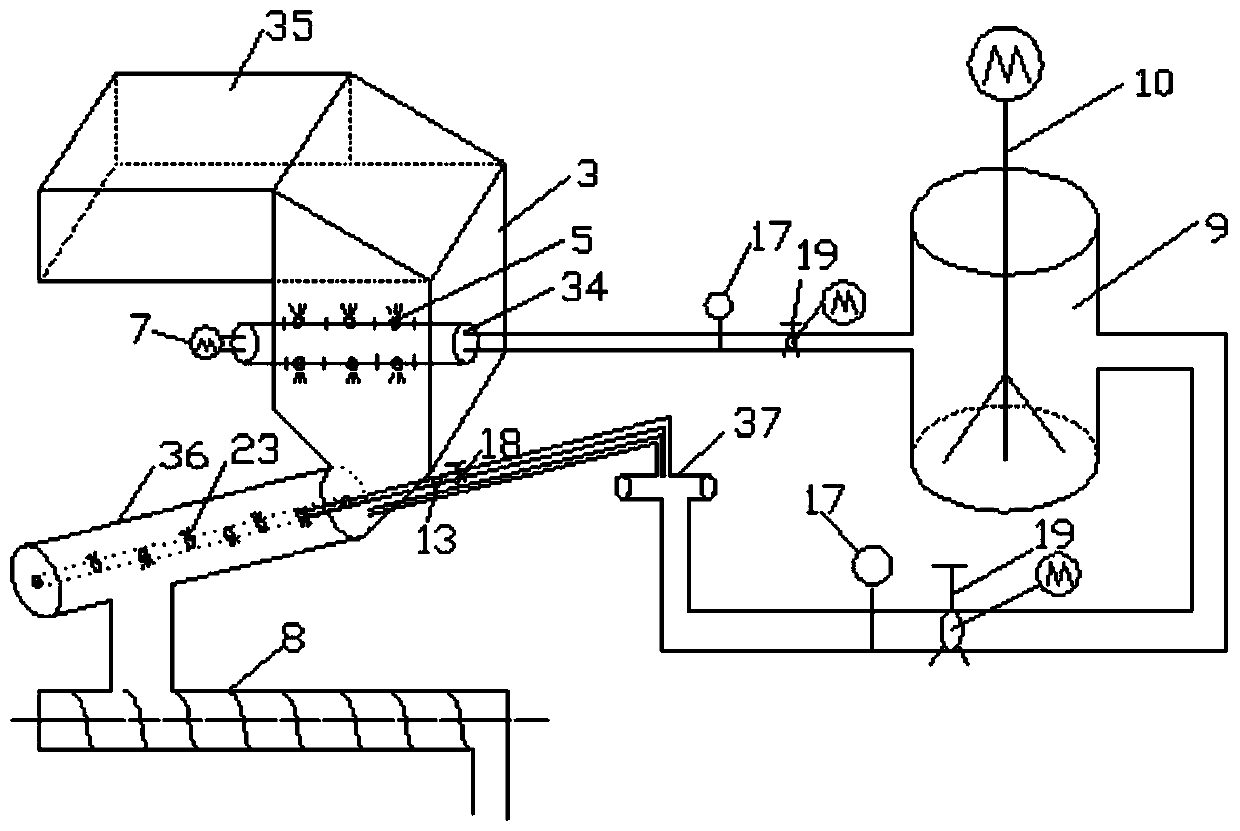

Integrated seed cotton vacuum drying and cleaning processing system and operating method thereof

InactiveCN102766910AReduce lossHeating evenlyVegetable fibre separation from seedsDrying machine combinationsPluckerSpray nozzle

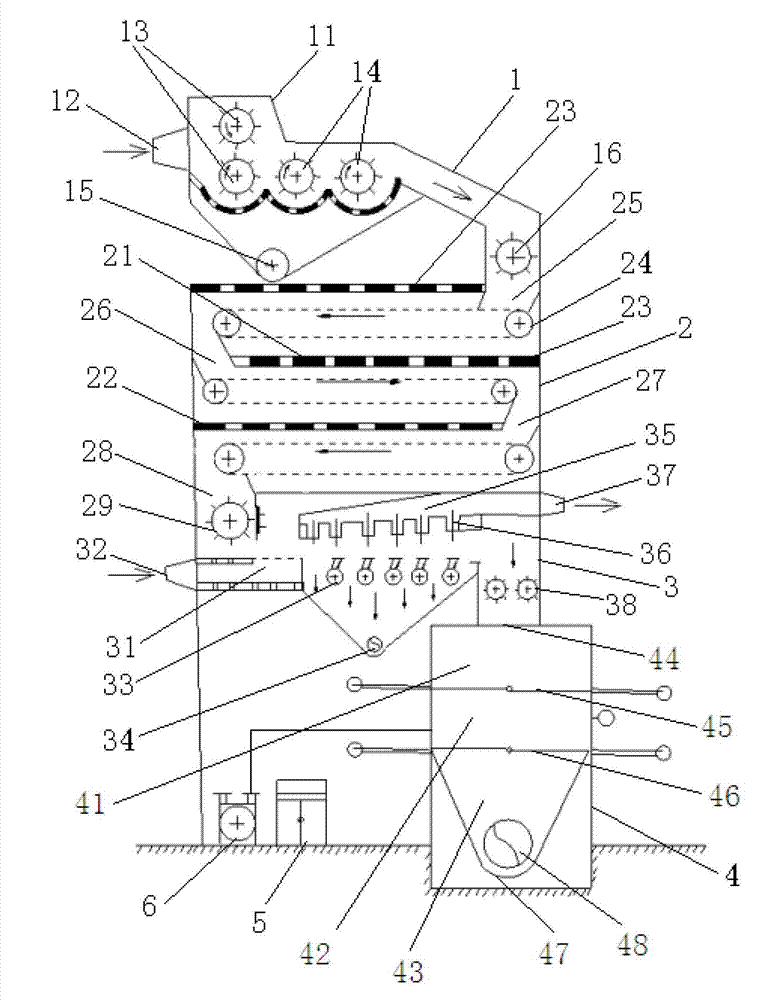

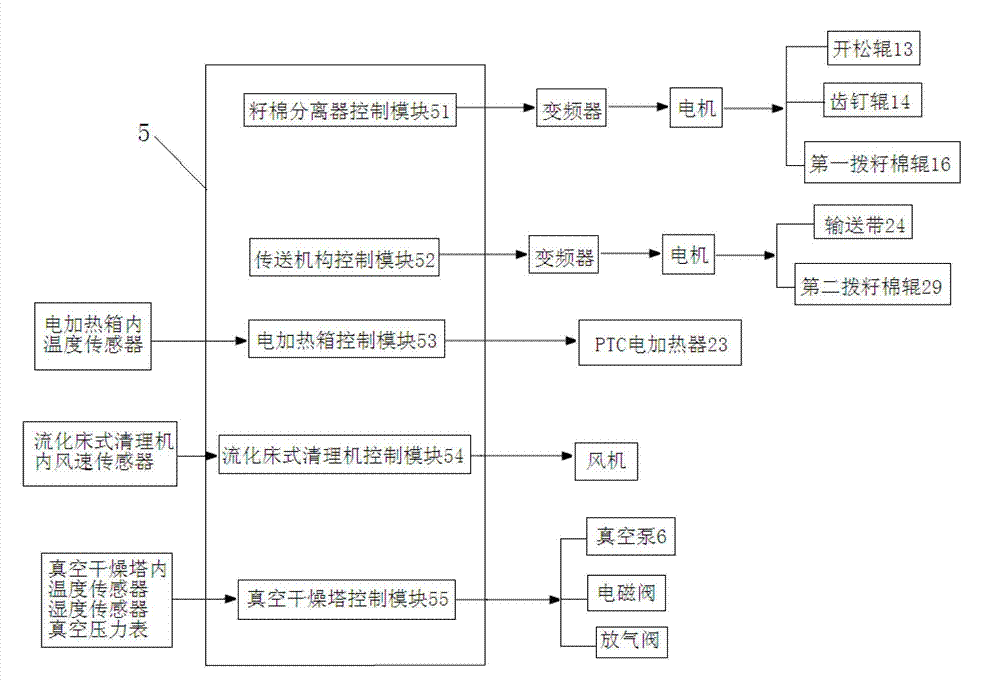

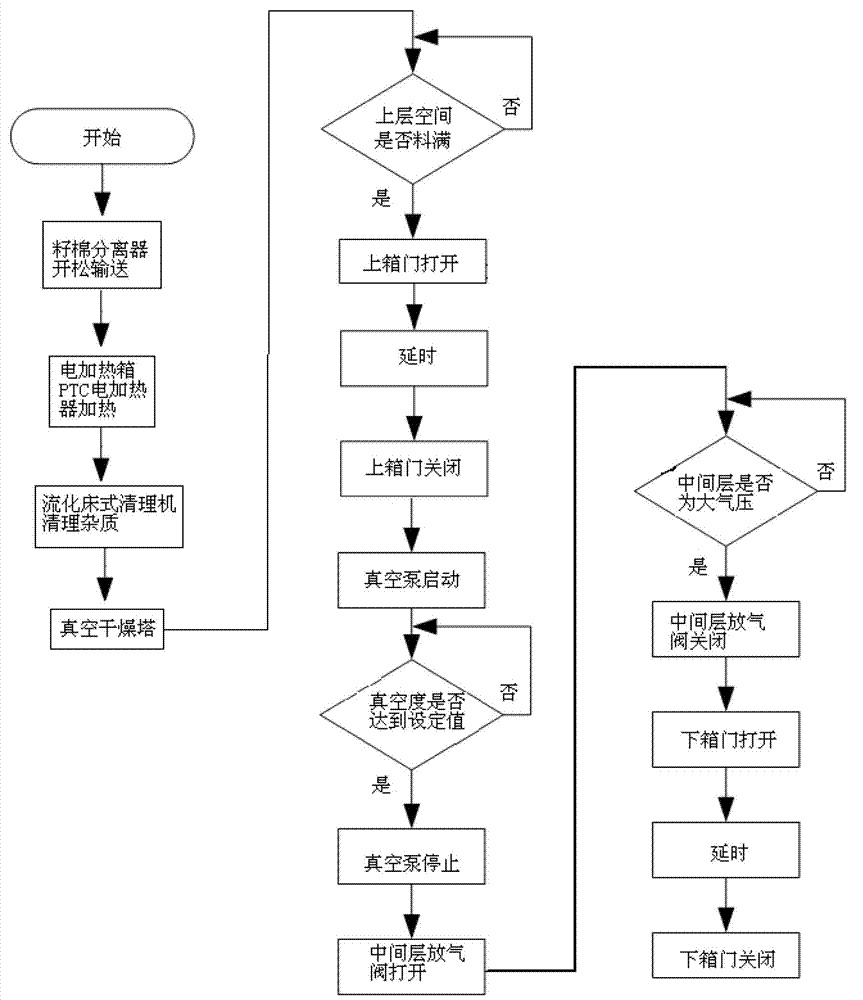

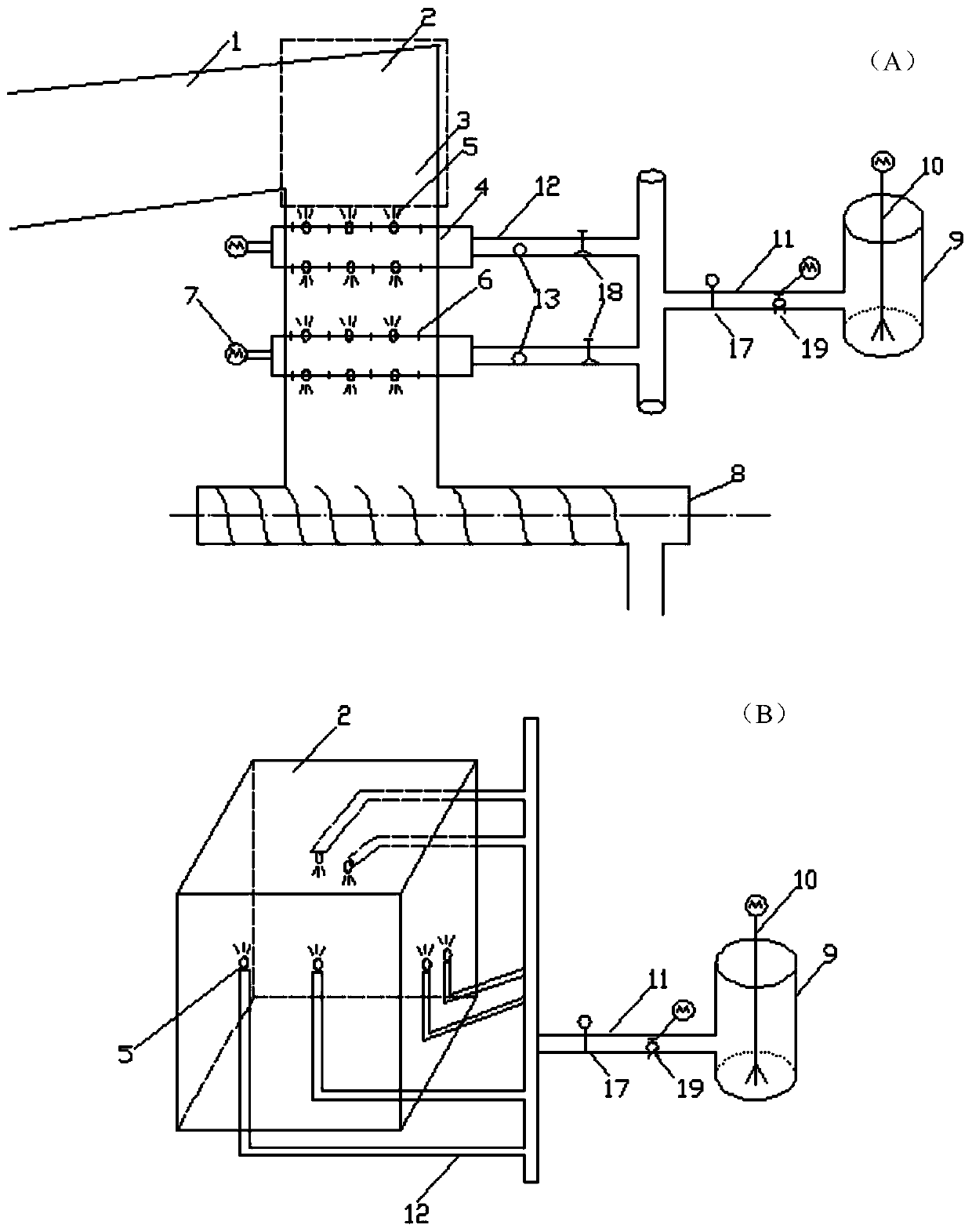

The invention relates to an integrated seed cotton vacuum drying and cleaning processing system and an operating method thereof. The processing system is characterized by comprising a seed cotton separator, an electrical heating box, a fluidized-bed type cleaner, and a vacuum drying tower which are arranged integrally; the seed cotton separator comprises an inlet and an outlet of a separator shell, wherein a plucker roller, a tooth-pin roller, and a first seed cotton stripping roller are arranged in the separator shell; the interior of the electrical heating box is divided into a plurality of layers of spaces, and a conveying belt and a plurality of heaters are arranged in each layer of the spaces; an air exhaust port flat plate is arranged in the fluidized-bed type cleaner; a group of jet nozzles are arranged behind the air exhaust port flat plate; a sundry removing auger and an air suction port flat plate are respectively arranged below and above the jet nozzles; a cleaner outlet is arranged on the fluidized-bed type cleaner; the vacuum drying tower is divided into an upper layer space, a middle layer space and a lower layer space; the top of the upper layer space is normally open, and a two halves type upper box door is arranged at the bottom of the upper layer space; a two halves type lower box door is arranged at the bottom of the middle layer space which is connected with a vacuum pump; and the bottom of the lower layer space is normally open, and is provided with a cotton conveying auger.

Owner:CHINA COTTON INDS +2

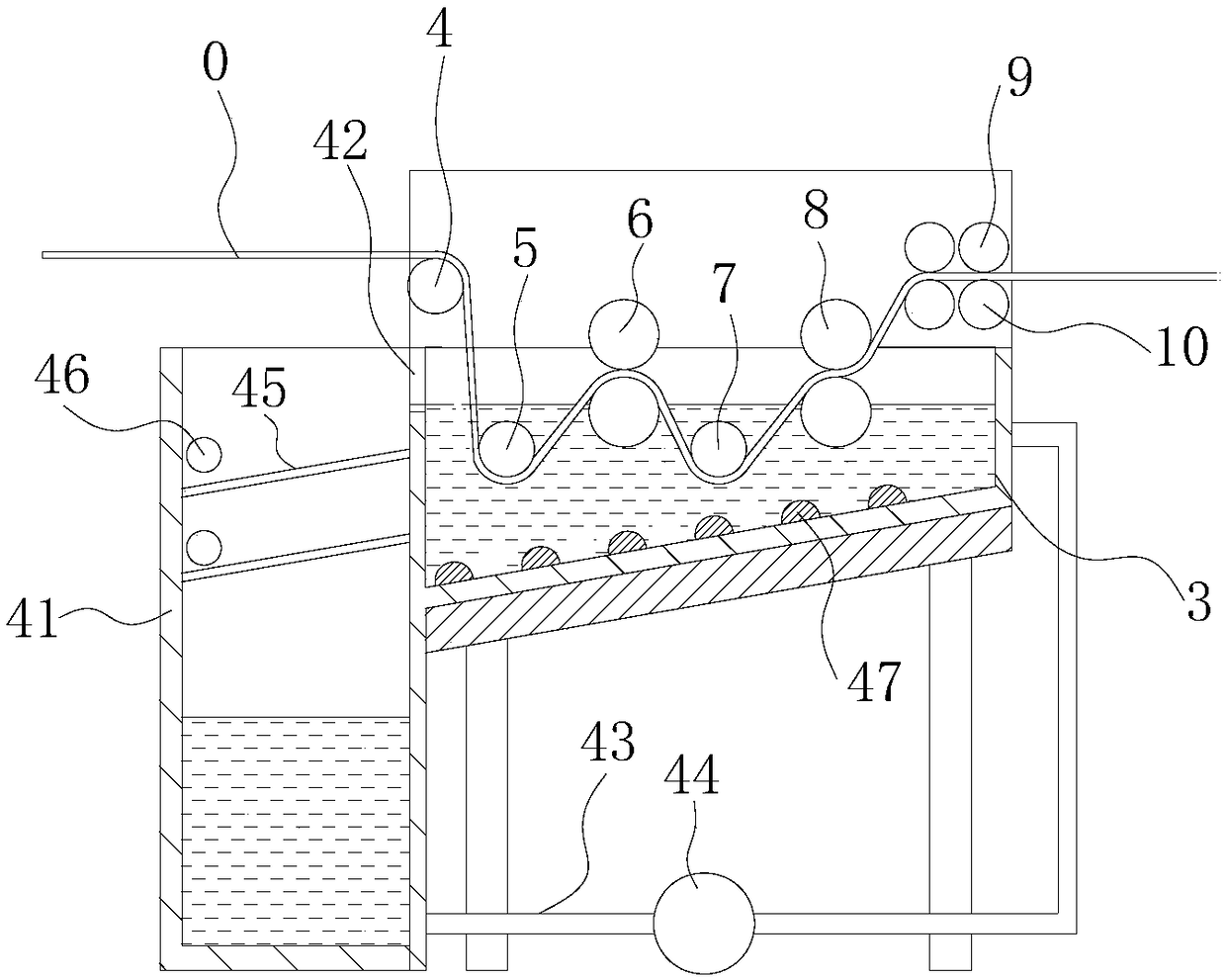

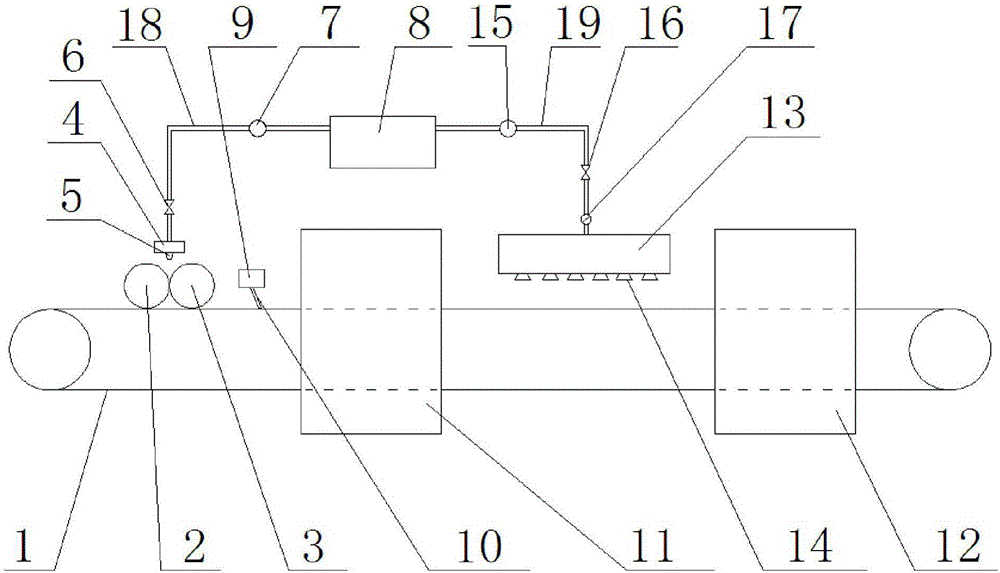

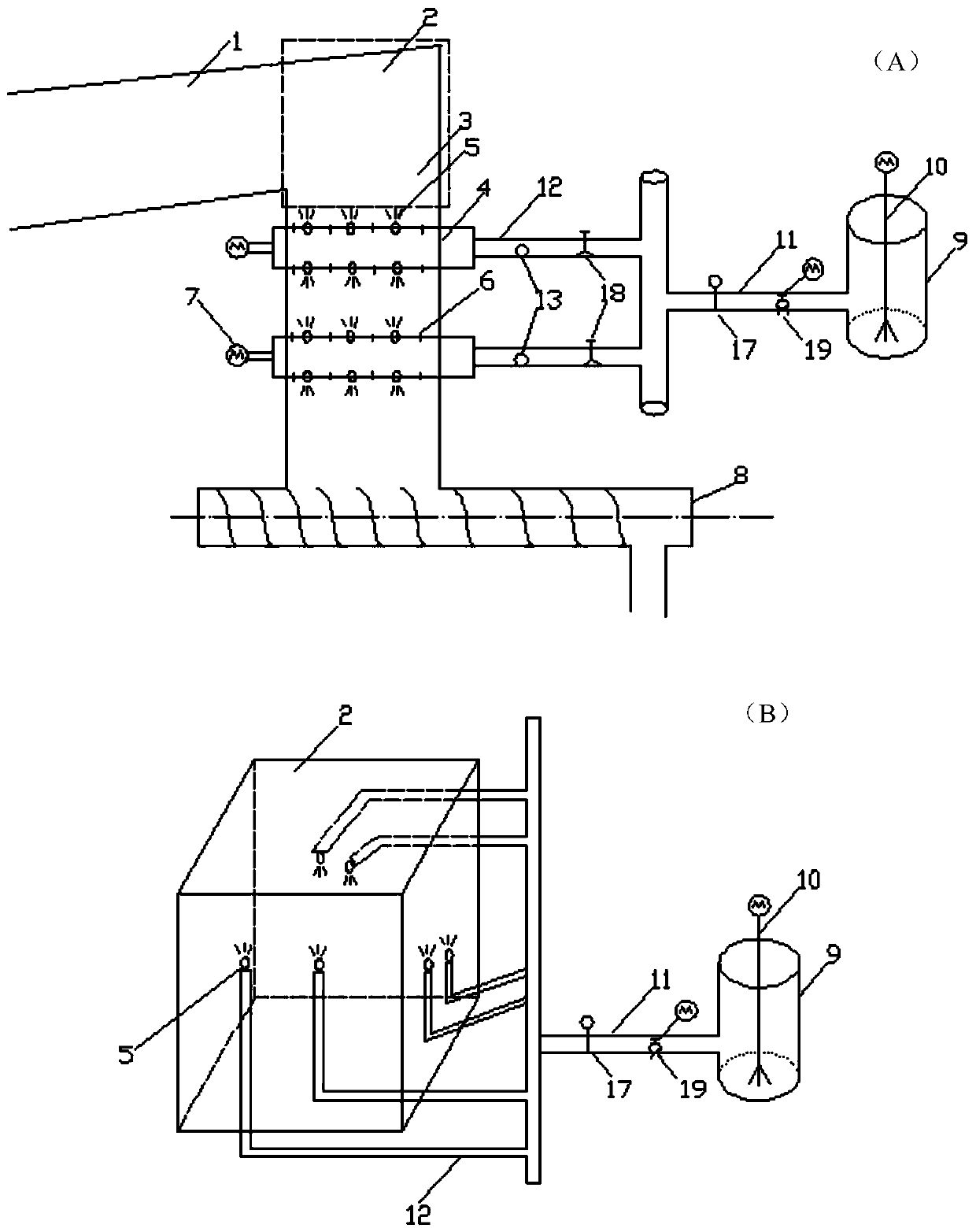

Quick-dry type sizing machine

ActiveCN109440333ALow moisture regainReduce energy consumptionLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsYarnPulp and paper industry

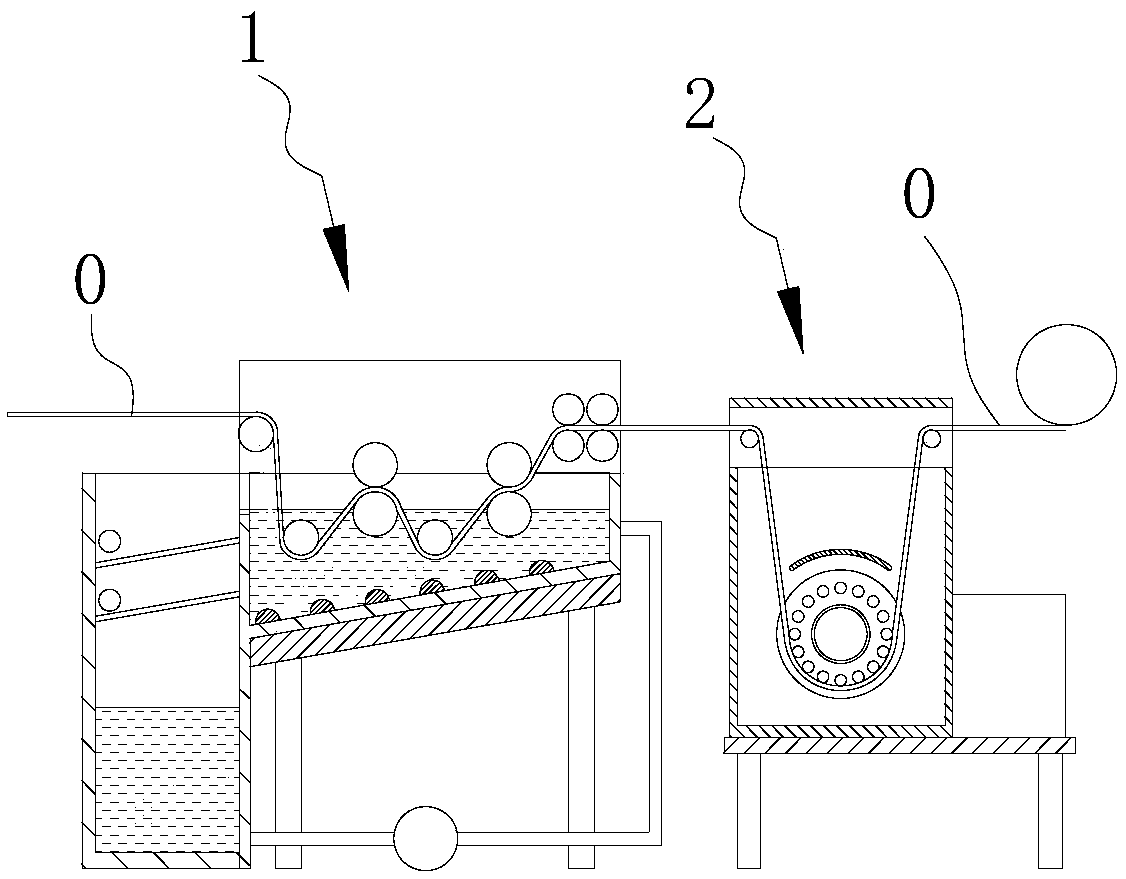

The invention relates to the technical field of textiles and aims to provide a quick-dry type sizing machine capable of sharply reducing moisture regain before drying. The technical scheme includes that the quick-dry type sizing machine comprises a sizing machine body and a drying box in sequential arrangement along a yarn conveying direction; the sizing machine body comprises a sizing tank whichis provided with a sizing mechanism; the sizing mechanism comprises a yarn guide roller, a first immersion roller, a first sizing roller group, a second immersion roller, a second sizing roller groupand a dewatering roller group in sequential arrangement along a yarn conveying direction. Each of the first sizing roller group and the second sizing roller group comprises an upper pressing roller and a lower sizing roller, and yarns penetrate a space between the upper sizing roller and the pressing roller. The dewatering roller group comprises an upper suction roller and a lower suction roller,and the yarns penetrate a space between the upper suction roller and the lower suction roller. Before the yarns enter the drying box, the yarn moisture regain can be reduced, and subsequent drying isfacilitated.

Owner:叶江波

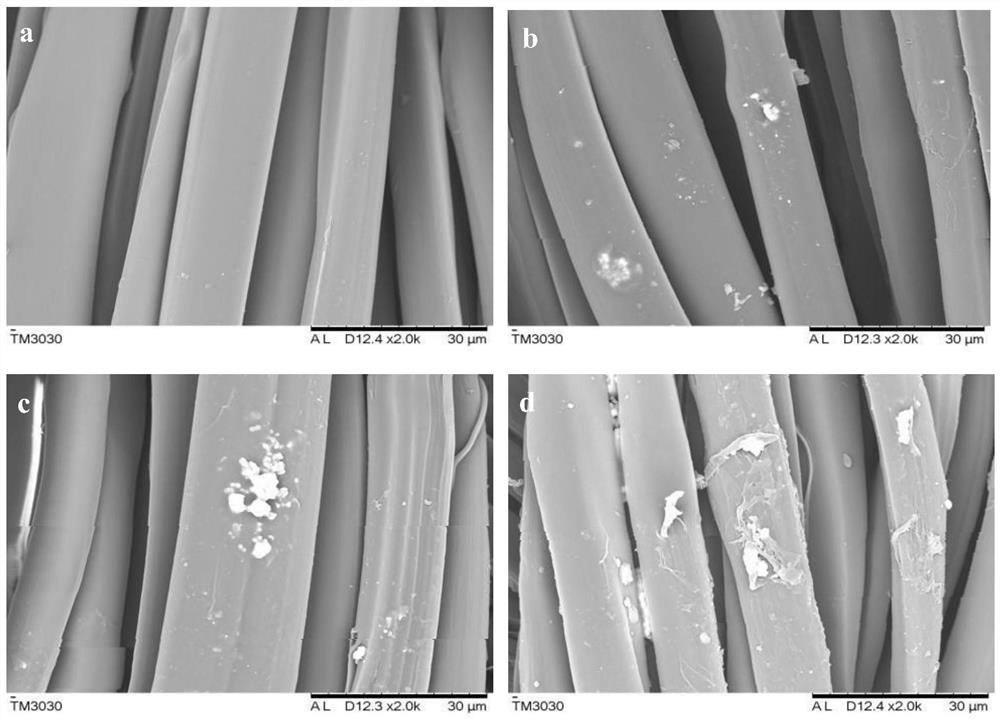

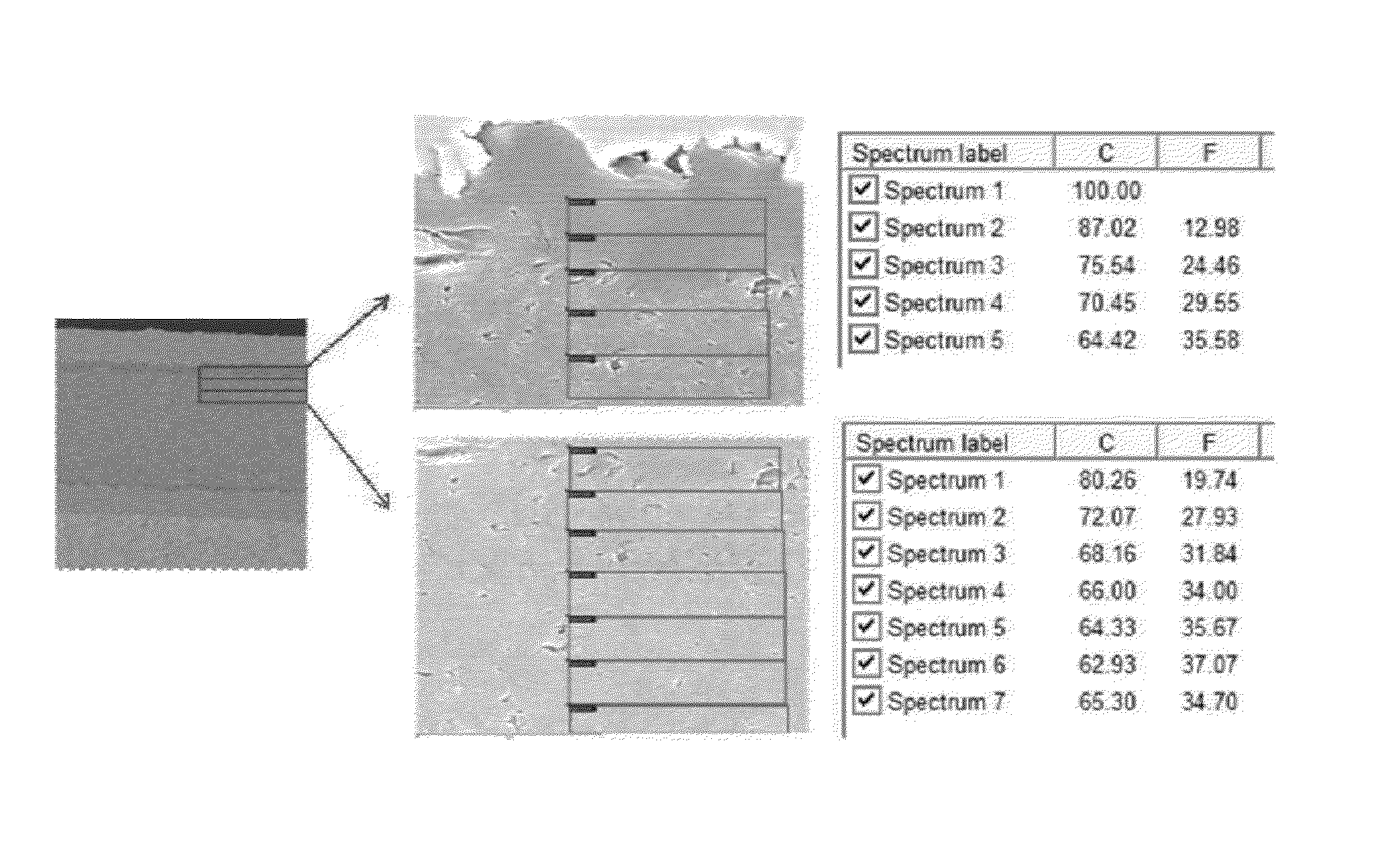

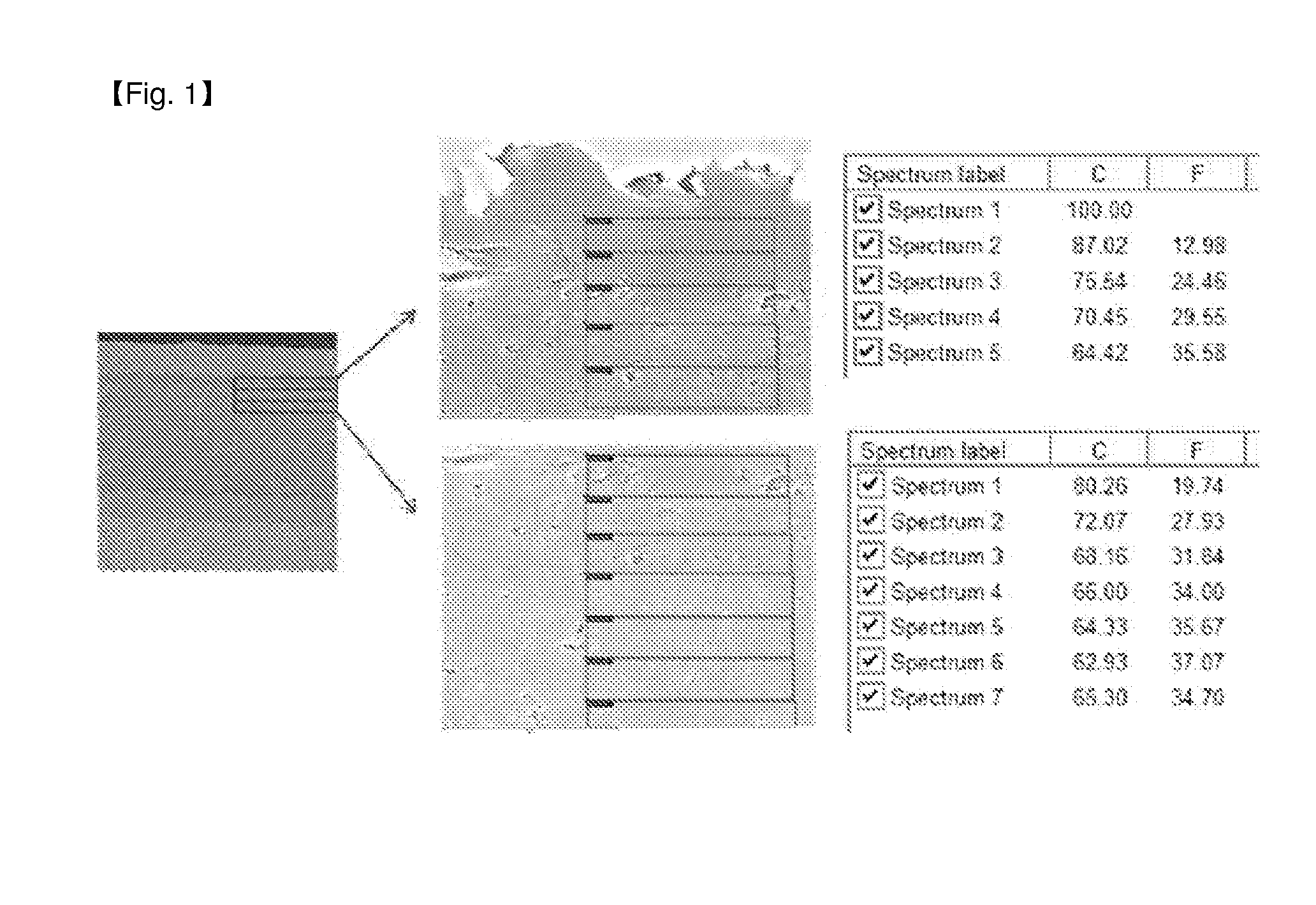

Fabrication method of super-hydrophobic/super-hydrophilic electrolyte lithium battery separator

InactiveCN109768205AImprove performanceImprove Coulombic efficiencyMaterial nanotechnologyLi-accumulatorsNanoparticleSilanes

The invention discloses a method for fabricating a super-hydrophobic / super-hydrophilic electrolyte lithium battery separator. The method comprises the steps of dispersing nanoparticle and organic silane in an alcohol-water mixed system with ultrasound, and adding an acid or an alkali as a catalyst so that the nanoparticle and the organic silane generate hydrolytic condensation reaction to obtain an organic silane polymer / nanoparticle composite suspension liquid; centrifugally collecting a precipitant, and performing drying to obtain super-hydrophobic nanoparticle; adding the super-hydrophobic,a conductive carbon material and a binding agent into a dispersing agent after the super-hydrophobic and the conductive carbon material are mixed and grinded, and performing stirring and ultrasound to obtain uniform paste; and finally, spraying the paste onto a surface of a lithium battery substrate separator, and performing hot-curing to obtain the super-hydrophobic / super-hydrophilic electrolytelithium battery separator after drying. Bionic superinfiltration expression is initially introduced into the design of the lithium battery separator, the prepared super-hydrophobic / super-hydrophilicelectrolyte lithium battery separator has excellent electrolyte wettabiity, high liquid absorption rate, retention rate and extremely low moisture regain rate, and the comprehensive performance of thelithium battery is remarkably improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

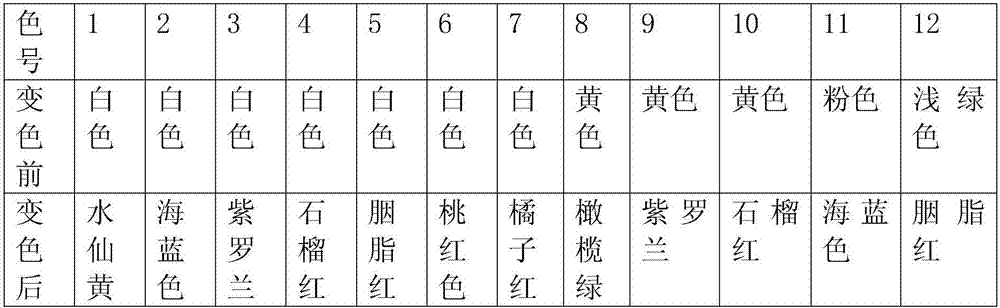

Production technology of discoloring antibacterial anti-ultraviolet fabric

The invention discloses a production technology of discoloring antibacterial anti-ultraviolet fabric. Through a yarn design, by using color characteristics of functional fiber, fancy yarn is developed and prepared to produce the fabric, and the textile meets functional requirements of the market and has fashion characteristics, so that the market space of the functional fiber is expanded. The production technology of discoloring antibacterial anti-ultraviolet fabric is antibacterial, anti-ultraviolet, cool, permeable in moisture and air, discoloring, fashionable and unique in fabric style, and can be used in both sides.

Owner:南通北岸纺织科技有限公司

Weed herbicide

A weed herbicide is prepared by the following raw materials by weight parts: 9.5 % of fomesafen, 2.5 % of quizalofop p ethyl, 23 % of clomazone, 42 % of 1,1'-dimethyl 4,4'-dichloro bipyridine, and 40 % of glyphosin. The weed herbicide can control various annual weeds, is strong in killing effect on perennial weeds, while underground stems and roots of the perennial weeds can sprout new branches, and has no influence on lignified brown stems and trunks. The weed herbicide is suitable for controlling weeds in orchards, mulberry gardens, rubber plantations and forests, as well as weeds at non-cultivated lands, ridges and road sides, and can control weeds for corns, sugarcanes, soybeans, nursery gardens and other wide-row crops by directed sprays. The weed herbicide can be further used as an auxiliary medicament used after a defoliant for machine harvested crops. For an ideal defoliating effect is not achieved when a harvesting stage is approaching after the crops are applied with the defoliant, the weed herbicide can be used to rapidly kill green tissues of the crops, dehydrate and dry the green tissues, and do not influence short-period stacking and transporting of the harvested fruits after a mechanical harvesting.

Owner:孟详贺

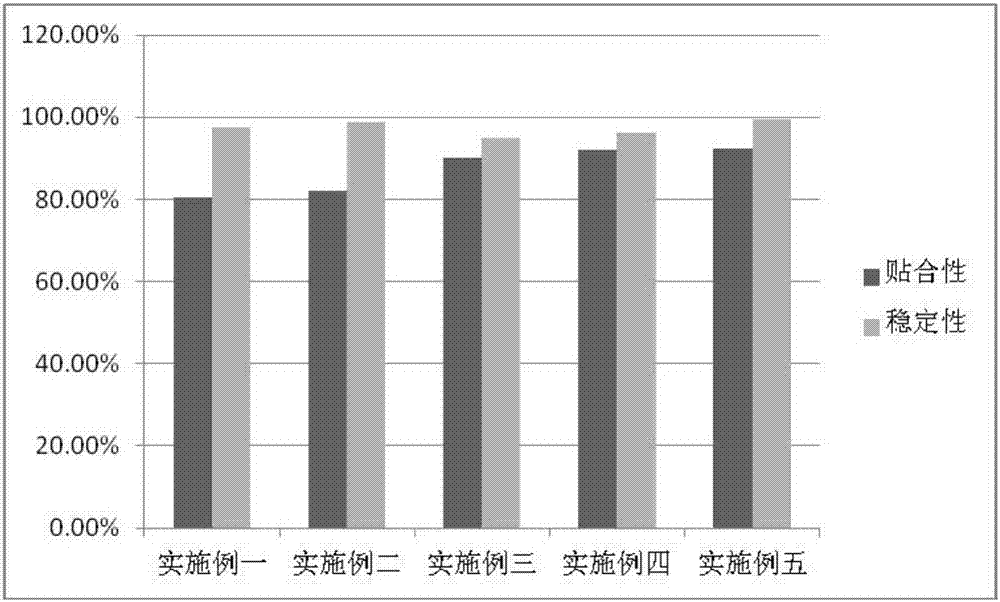

Anticorrosive rubber lining and preparation method thereof

InactiveCN107383442ASolve the problem of anti-corrosion performanceExtend effective lifeChemical industryPolymer science

The invention belongs to the technical field of rubber linings, in particular to an anti-corrosion rubber lining and its preparation method, which solves the shortcomings of the prior art such as the lining falling off, fast aging, loose fit, especially high water absorption and easy moisture regain, and proposes An anti-corrosion rubber lining and its preparation method, and the preparation method is widely used, involving petroleum, chemical, fertilizer, metallurgy, electric power acid-base storage tanks, reactors, pure steel equipment used in floor isolation layers, etc. Used in many industrial productions, it includes 20-40 parts of natural rubber, 8-16 parts of styrene-butadiene rubber, 0.5-1.5 parts of peptizer, 8-16 parts of high styrene, 10-20 parts of graphite powder, 20-20 parts of sulfur 30 parts, 0.5-2 parts of high-speed accelerator, 2-4 parts of dispersant. The anti-corrosion rubber lining of the invention has high hardness, strong tensile capacity, good ductility and simple manufacturing process, can be constructed in workshops or on site, and is easy to realize.

Production method of flame-retardant high-temperature resistant pre-oxidized fiber aramid fiber blended yarn

The invention relates to a flame-retardant high-temperature resistant pre-oxidized fiber aramid fiber blended yarn and a production method thereof. The blended yarn is composed of 50-90mass% of pre-oxidized fiber chopped fibers and 50-10mass% of aramid fiber 1313 chopped fibers; the production process flow comprises the following steps of carrying out pretreatment on the pre-oxidized fiber choppedfibers and the aramid fiber chopped fibers separately; performing cotton package mixing on the pre-oxidized fiber chopped fibers and the aramid fiber 1313 chopped fibers in an opening picking procedure to prepare cotton rolls; preparing the cotton rolls into carding silvers in a cotton carding procedure; preparing the carding silvers into drawing silvers through two drawing procedures; preparingthe drawing silvers into roving through a roving procedure; preparing the roving into spun yarns through a spinning procedure; and preparing the spun yarns into a pre-oxidized fiber aramid fiber blended yarn spool through a spooling procedure. The method combines the pre-oxidized fiber and aramid fiber 1313 flame-retardant high-temperature resistant advantages, overcomes the shortcoming of poor spinning performance of the pre-oxidized fiber, and the woven pre-oxidized fiber aramid fiber 1313 blended yarn has excellent quality.

Owner:YANCHENG INST OF IND TECH

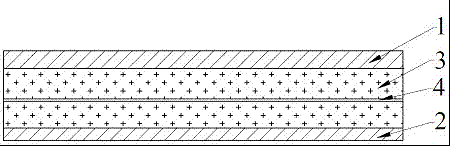

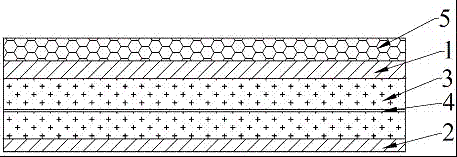

Metal surface plant fiber composite plate, production method of metal surface plant fiber composite plate and rail train floor

InactiveCN104325987AReduce dependenceHigh densityAxle-box lubricationRailway bodiesSurface layerMetal alloy

The invention discloses a metal surface plant fiber composite plate, which comprises a first surface layer and a second surface layer, wherein a middle layer is arranged between the first surface layer and the second surface layer in a bonding way, the first surface layer and the second surface layer are metal plates or metal alloy plates, and the middle layer is a no-glue plywood pressed by natural fiber and synthesized fiber felt. The invention also discloses a rail train floor and a production method of the metal surface plant fiber composite plate. The metal surface plant fiber composite plate has the advantages that the self weight is light, the mechanical performance, the shock resistance, the sound-absorbing noise reduction and the heat insulation are excellent, the production method is simple, and the operation is easy. The metal surface plant fiber composite plate is used for the rail train floor, the long-time high load can be borne, and the recycling and reusing can also be realized.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

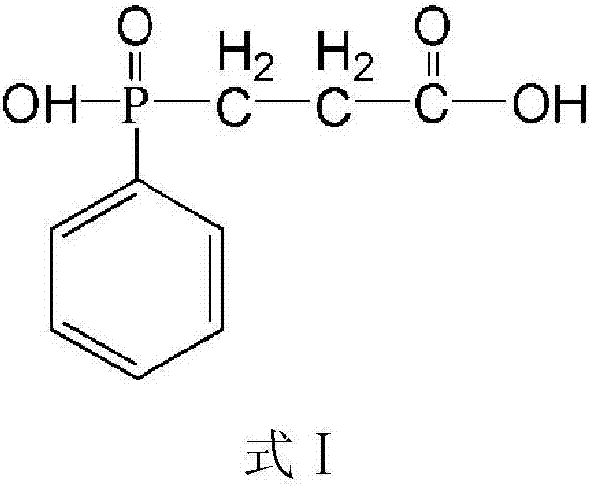

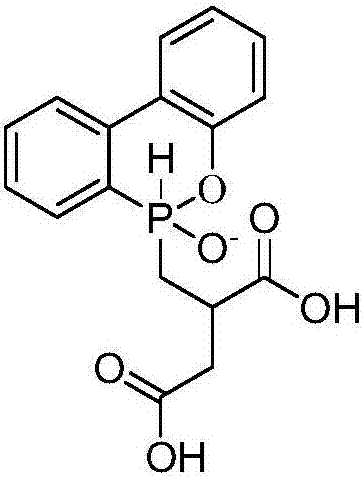

Flame retardant polyamide with low moisture-regain rate and preparation method of polyamide

The invention discloses flame retardant polyamide with a low moisture-regain rate and a preparation method of the polyamide. The preparation method of the flame retardant polyamide with the low moisture-regain rate comprises the following steps: a flame retardant containing phosphorus, a long carbon chain diamine and a dihydric alcohol are subjected to a pre-polymerization reaction in water, and a polymerization reaction is performed to obtain a flame retardant prepolymer; and the flame retardant prepolymer and a polyamide 66 salt are subjected to a co-polymerization reaction, and therefore the flame retardant polyamide with the low moisture-regain rate is obtained. According to the invention, the long carbon chain diamine, the dihydric alcohol and the flame retardant containing the phosphorus are subjected to polymerization to obtain the flame retardant prepolymer, the flame retardant prepolymer and the polyamide 66 salt are subjected to polymerization, and therefore the flame retardant polyamide copolymer with the low moisture-regain rate is obtained, wherein the polyamide has good mechanical properties, the low moisture-regain rate and flame retardance. The flame retardant polyamide with the low moisture-regain rate is applied to the fields such as spaceflight aviation and electronics and electrical appliances. The flame retardant polyamide with the low moisture-regain rate has good flame retardance, the low moisture-regain rate, has no halogens or red phosphorus, is friendly to environments, and has excellent mechanical properties. According to the preparation method provided by the invention, the prepared polyamide material is simple in process, has good mechanical properties, the low moisture-regain rate and the flame retardance, and is suitable for large-scale promotion.

Owner:THE QUARTERMASTER EQUIP INST OF THE LOGISTICAL SUPPORT DEPT CMC

Straw fiber-hemp fiber mixed non-woven fabric used for seamless wallpaper, and preparation method thereof

InactiveCN105133328AImprove toughnessIncrease elasticityLayered productsVegetal fibresMethacrylatePolyvinyl alcohol

The invention discloses a straw fiber-hemp fiber mixed non-woven fabric used for seamless wallpaper. The straw fiber-hemp fiber mixed non-woven fabric is prepared from, by weight, 200 to 205 parts of straw, 100 to 104 parts of raw hemp, an appropriate amount of NaOH, an appropriate amount of water, 0.7 to 0.75 part of polyvinyl alcohol, 0.2 to 0.3 part of nano aluminium hydroxide, 0.2 to 0.3 part of epoxidized lignin, 0.2 to 0.3 part of trifluoroethyl methacrylate, 0.2 to 0.3 part of dodecafluoroheptyl methacrylate, 5 to 6 parts of ethyl acetate, 0.3 to 0.4 part of polyaniline nano fiber, 0.3 to 0.4 part of nano polytetrafluoroethylene, and 0.05 to 0.1 part of dicumyl peroxide. The straw fiber-hemp fiber mixed non-woven fabric is low in moisture regain rate, possesses mildew resistance, is high in toughness and strength; adding of polyaniline nano fiber is capable of improving elasticity, water resistance, and durability of the straw fiber-hemp fiber mixed non-woven fabric; adding of nano aluminium hydroxide and epoxidized lignin is capable of improving heat resistance, flame resistance, and toughness of the straw fiber-hemp fiber mixed non-woven fabric.

Owner:陈杰

Straw fiber and bastose mixture nonwoven used for thermal insulation seamless wallpaper and preparation method of straw fiber and bastose mixture nonwoven

InactiveCN105862493AExtended service lifeImprove heat resistanceSpecial paperPaper/cardboardMethacrylateThermal insulation

The invention discloses straw fiber and bastose mixture nonwoven used for thermal insulation seamless wallpaper. The straw fiber and bastose mixture nonwoven is prepared from the following raw materials in parts by weight: 200-205 parts of straw, 100-104 parts of original hemp, a proper quantity of NaOH and water, 0.8-0.85 part of polyvinyl alcohol, 0.5-0.6 part of nano-montmorillonite, 0.2-0.3 part of trifluoroethyl methacrylate, 0.2-0.3 part of dodecafluoroheptyl methacrylate, 5-6 parts of ethyl acetate, 0.2-0.3 part of polyethylene wax, 0.4-0.5 part of potassium tetraborate, 1.3-1.5 parts of far-infrared ceramic powder, 2-2.5 parts of alumina-silicate ceramic fiber, 0.3-0.4 part of nano polytetrafluoroethylene and 0.05-0.1 part of cumin peroxide. The nonwoven uses the nano-montmorillonite, the potassium tetraborate, the far-infrared ceramic powder and the alumina-silicate ceramic fiber, can emit far-infrared and improves the thermal insulation heat-resistant performance and the humidity resistance of the nonwoven.

Owner:CHUZHOU SHALANG NEW MATERIAL TECH CO LTD

Environment-friendly non-glue cotton

The invention provides environment-friendly non-glue cotton, comprising the following components in percentages by mass: 25-30% of cotton fiber, 50-65% of polyester fibers and 15-25% of corn fibers, wherein the cotton fibers are collagen coated cotton fibers, by utilizing the collagen, nutrients necessary for human skin can be given, affinity with a human body and comfortable sensation of the human body can be increased, and multiple healthcare functions are provided, so that the using performance and the social and economic benefits of the non-glue cotton are improved. The polyester fibers are modified by bamboo charcoal, so that a micro-porous structure is provided, the anti-static electricity capacity, the antibacterial ability and the anti-fungus capacity of the non-glue cotton are increased. The corn fibers have small specific gravity, the melting point is up to 175 DEG C, the moisture regain is lower, degradation products of the corn fibers are harmless lactic acid, carbon dioxide and water, toxic substances cannot be generated during combustion, and the corn fibers are novel environment-friendly fibers.

Owner:ANHUI LION GOOSE PROD

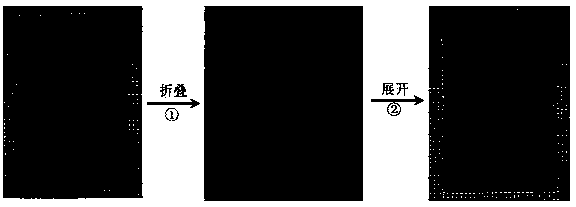

Corrugated paper gluing device

InactiveCN105064130ALow moisture regainLow moisture permeabilityPaper/cardboardPulp material addition processesSpray nozzlePaper sheet

The invention relates to a corrugated paper gluing device which comprises a conveying belt, as well as a first gluing roller, a second gluing roller, a first drying oven, a second gluing cavity and a second drying oven all sequentially arranged in the conveying direction of the conveying belt, wherein a first gluing cavity is formed above the first gluing roller and the second gluing roller; a plurality of gluing spray nozzles facing the first gluing roller and / or the second gluing roller are uniformly arranged on the first gluing cavity; the first gluing cavity is communicated with a glue bucket through a first gluing pipe, and a first gluing pump is arranged on the first gluing pipe; the second gluing cavity is formed above the conveying belt; a plurality of nozzles facing the upper surface of the conveying belt are uniformly arranged on the second gluing cavity; the second gluing cavity is communicated with the glue bucket through a second gluing pipe, and a second gluing pump is arranged on the second gluing pipe. The corrugated paper gluing device has the benefits that two layers of films are formed on the surface of corrugated paper, so that the water resistance is effectively improved, the moisture permeability of the surface of the corrugated paper is reduced, finally, the moisture regain of the corrugated paper is reduced, and the problem of reduction of finished paper strength of corrugated paper, caused by moisture absorption, is successfully solved.

Owner:桂林市独秀纸品有限公司

Straw fiber and jute fiber blended non-woven fabric for warming anti-bacterial, environment-friendly and seamless wall paper and preparation method for non-woven fabric

InactiveCN105155137AImprove toughnessExtended service lifeNon-woven fabricsEnvironmental resistanceAcrylic resin

The invention discloses a straw fiber and jute fiber blended non-woven fabric for a piece of warming anti-bacterial, environment-friendly and seamless wall paper. The non-woven fabric is made from the following raw material according to weight by parts: straw taking up of 200 to 205 parts, original hemp of 100 to 104 parts, proper amount of NaOH, proper amount of water, polyving akohol of 0.8 to 0.85 part, lignin of 0.5 to 0.6 part, methylacrylic acid trifluro-ethyl ester of 0.2 to 0.3 parts, methylacrylic acid Dodecafluoroheptyl of 0.2 to 0.3 part, ethyl acetate of 5 to 6 parts, tea tree essential oil of 0.3 to 0.4 part, activated carbon fibers of 2.5 to 3 parts, nanometer polytetrafluoroethylene of 0.3 to 0.4 part, and peroxidation cumin of 0.05 to 0.1 part. With the use of the tea tree essential oil and the activated carbon fibers, the non-woven fabric has performance of preventing bacteria and absorbing harmful gas; and tenacity, tear-resistance and low temperature-resistance of the non-woven fabric are enhanced due to the use of the polyurethane acrylic resin and the lignin.

Owner:陈杰

Strong hydrophobic silk fabric and preparation method thereof

InactiveCN111945425AReduce surface tensionReduce energy consumptionLiquid repellent fibresBiochemical treatment with enzymes/microorganismsPolymer scienceWarm water

The invention discloses a preparation method of a strong hydrophobic silk fabric.A specifically designed grafting system comprising laccase, an acetic acid buffer solution with the pH value of 4-5, lauryl gallate, ethanol, a reaction medium, a catalytic mediator and a copper salt is adopted. The preparation method comprises the following steps: preheating the grafting system at the temperature of30-60 DEG C for 10-15 minutes, keeping the temperature, adding the pretreated silk fabric according to the bath ratio of 1: 50, carrying out a reaction for 2-6 hours, sequentially carrying out cleaning with cold water and warm water, drying and extracting, and thus obtaining the strong hydrophobic silk fabric. The method is simple and mild in reaction, high in catalytic activity, high in graftingspeed and high in monomer grafting rate, and the hydrophobic property of the silk fabric produced by the method is remarkably improved. The invention also discloses the strong hydrophobic silk fabricproduced by the method, and the silk fabric is low in silk fiber surface energy, strong in hydrophobic property and lasting in hydrophobic effect.

Owner:JIANGSU HUAJIA SILK +1

Preparation method of compound food deoxidizing agent

ActiveCN106666323AGood deoxidation effect at low temperatureIncreased oxygen absorption rateFood preservationFood ingredient for microbe protectionNitrogen gasMoisture regain

The invention discloses a preparation method of a compound food deoxidizing agent, belongs to the technical field of deoxidizing agent preparation, and aims to overcome the defects of poor refreshment and corrosion prevention effects due to high moisture regain and low oxygen absorbing rate after use of the conventional iron-based deoxidizing agent with a poor low-temperature deoxidizing effect. The preparation method of the compound food deoxidizing agent comprises the following steps: making montmorillonite serving as a filling substance load platinum ions provided through a chloroplatinic acid solution; smelting and wrapping the platinum ions at a high temperature to increase the catalyzing efficiency; burning magnesium powder in nitrogen gas to generate magnesium oxide, and smelting the magnesium oxide on the surface of the filling substance; oxidizing the humic acid with hydrogen peroxide; sulfonating the humic acid oxide through sulfur trioxide to improve absorption of sulfur dioxide and ammonia gas; mixing the humic acid oxide with iron powder and sodium hydrosulfite to prepare the compound food deoxidizing agent. Compared with the conventional deoxidizing agent, the compound food deoxidizing agent prepared by the method has the advantages that the oxygen absorbing rate is increased by 18 to 22 percent, and the moisture regain after use is lowered by 26 to 35 percent.

Owner:浙江华味亨食品有限公司 +1

Antistatic rice straw fiber and hemp fiber mixed nonwoven fabric for seamless wall paper and preparation method thereof

InactiveCN105200659AExtended service lifeAntistaticSynthetic resin layered productsNon-woven fabricsMethacrylateEpoxy

The invention discloses an antistatic rice straw fiber and hemp fiber mixed nonwoven fabric for seamless wall paper. The nonwoven fabric is prepared from the raw materials in parts by weight: 200-205 parts of rice straw, 100-104 parts of raw hemp, a proper amount of NaOH, a proper amount of water, 0.8-0.85 part of polyvinyl alcohol, 0.2-0.3 part of trifluoroethyl methacrylate, 0.2-0.3 part of dodecafluoroheptyl methacrylate, 5-6 parts of ethyl acetate, 0.5-0.6 part of seaweed charcoal, 4-4.5 parts of polyaniline short fiber, 0.6-0.7 part of epoxy resin, 0.2-0.3 part of triethylene tetramine, 0.3-0.4 part of nano poly(tetrafluoroethylene), and 0.05-0.1 part of dicumyl peroxide. By using seaweed charcoal and polyaniline short fiber, the nonwoven fabric has performance of resisting static electricity and emitting far infrared rays; by using epoxy resin and triethylene tetramine, the flexibility and strength of the nonwoven fabric are improved.

Owner:陈杰

A method for preparing printing paper with moisture-proof function

InactiveCN108894047ALower contact angleImprove moisture resistanceSpecial paperPaper/cardboardPolyvinyl alcoholRoom temperature

The invention discloses a printing paper preparation method with moisture-proof function, which comprises the following steps: step 1, starch is dispersed into water to prepare a printing paper with aconcentration of 30 40% slurry, follow by 0.01 0.04% starch branching enzyme, raising the temperature to 35 45. Degree. C., reaction 15. Degree. C 25 min, and then adde concentrated sulfuric acidto that mixture for reaction 4 6 min, and then adde that polyvinyl alcohol, and stirring the mixture continuously for 12 16min, cool to room temperature, standby. The purpose of the invention is toprovide a method for preparing printing paper with moisture-proof function. Compared with the prior art, the printing paper has good moisture-proof effect, high use value and good application prospect.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

Flexible metal laminate

ActiveUS9307638B2Low dielectric constantOptimized coefficientDielectric materialsCoatingsPolymer resinPolymer chemistry

Owner:GUANGDONG SHENGYI SCI TECH

Dyeing and finishing process of cuproammonia viscose acetate fiber fabric

ActiveCN104905436BDimensionally stableHigh color fastnessSucessive textile treatmentsDry-cleaning apparatus for textilesCuprammonium rayonPolymer science

The invention discloses a cuprammonium-viscose-acetate fiber fabric and a dyeing process thereof, and belongs to the technical field of fabric dyeing. The cuprammonium-viscose-acetate fiber fabric is characterized by being formed by interweaving three fibers comprising cuprammonium, viscose and acetate fiber. The dyeing process comprises the following steps: primary washing-pretreatment-secondary washing-acetate dyeing-tertiary washing-cuprammonium and viscose dyeing-quaternary washing-acid pickling to adjust the pH value and discharging from vat-primary drying-primary sizing-softening finish-secondary drying-secondary sizing, wherein the pretreatment is treatment with mild neutral treating fluid. According to the invention, the cuprammonium-viscose-acetate fiber fabric integrates the advantages of three fibers comprising cuprammonium, viscose and acetate fiber; the dyeing process realizes the dyeing of three fibers with different properties, is suitable for any proportion in the presence of three fibers comprising cuprammonium, viscose and acetate fiber, and ensures that the fabric has low shrinkage, and higher color fastness and strength, so as to have better wearability.

Owner:ZIBO DARANFANG SILK GRP

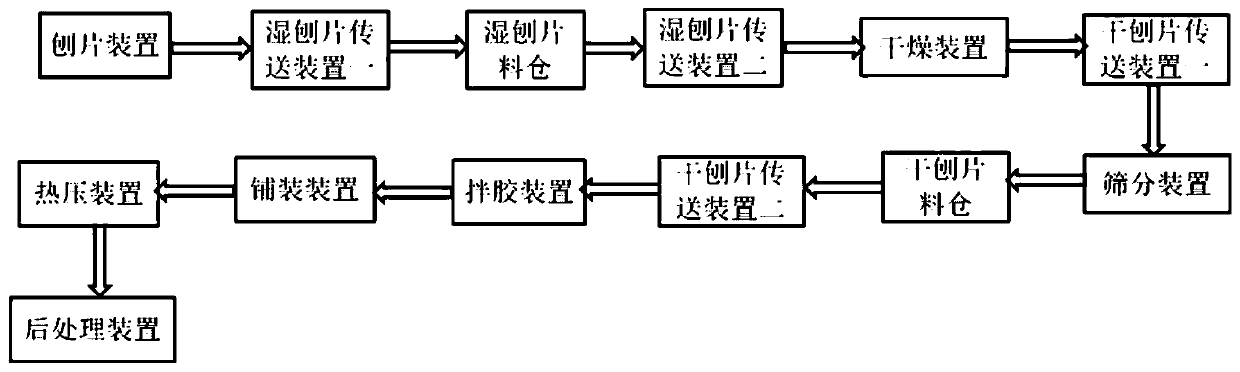

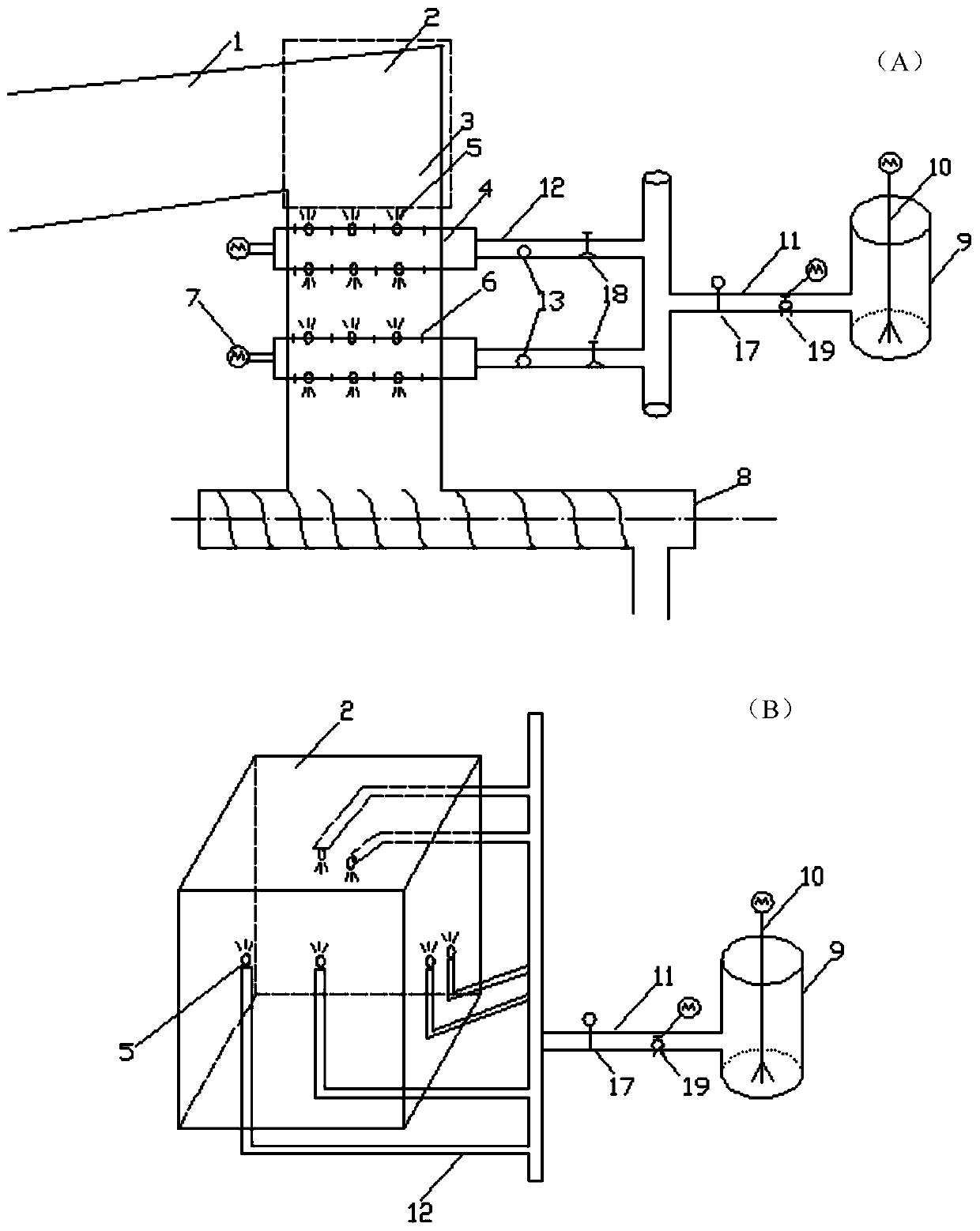

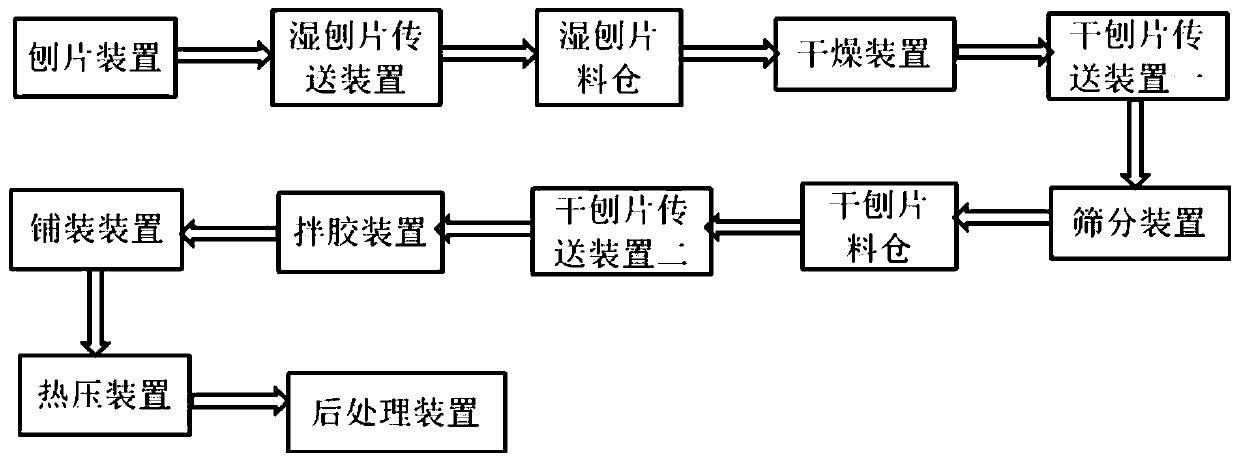

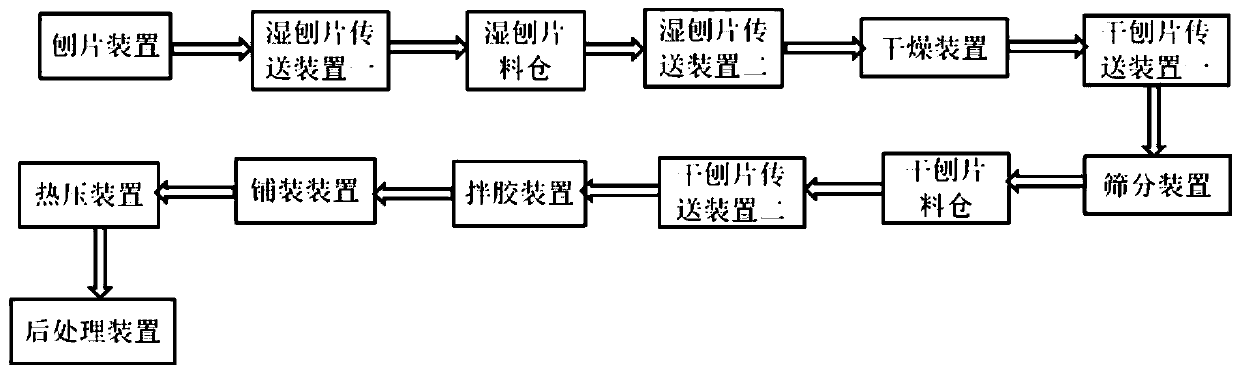

System and process for producing flame-retardant oriented strand board

ActiveCN109747019AGood adhesionIncrease coverageDomestic articlesFlat articlesAfter treatmentEngineering

The invention discloses a system and process for producing a flame-retardant oriented strand board. The system comprises a flaking device, a first wet flake conveying device, a wet flake bin, a secondwet flake conveying device, a drying device, a first dry flake conveying device, a screening device, dry flake bins (including the surface dry flake bin and the core dry flake bin), a second dry flake conveying device, glue mixing devices (including the surface dry flake glue mixing device and the core dry flake glue mixing device), a mat formation device, a hot-pressing device, and an after-treatment device and a flame retardant spraying structure used after hot-pressing. According to the system and process, a flame retardant is sprayed in multiple procedures to be sufficiently absorbed by flakes and is evenly distributed, and the flame-retardant oriented strand board obtained through the system and process has an excellent flame retardant property.

Owner:湖北宝源木业有限公司

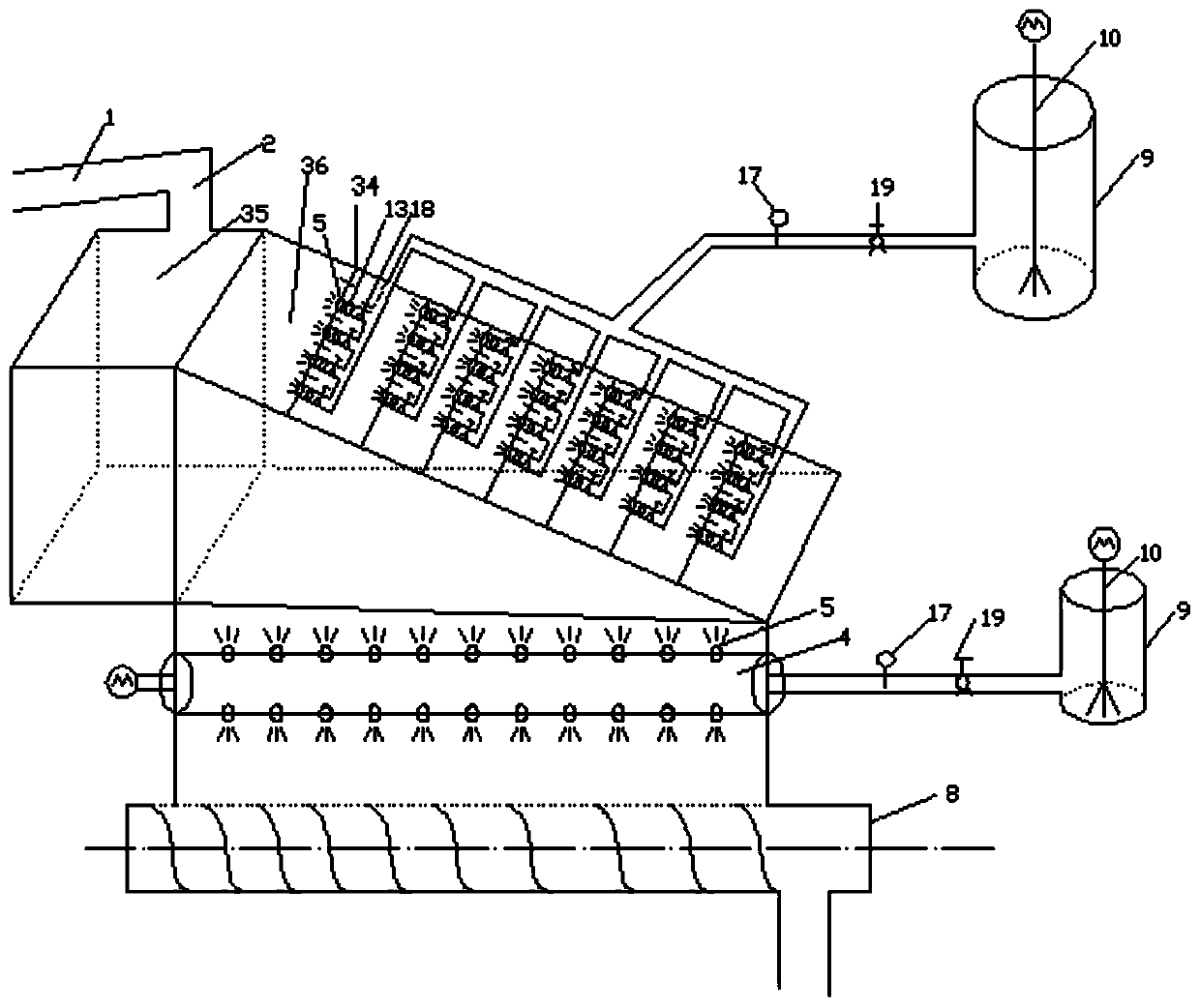

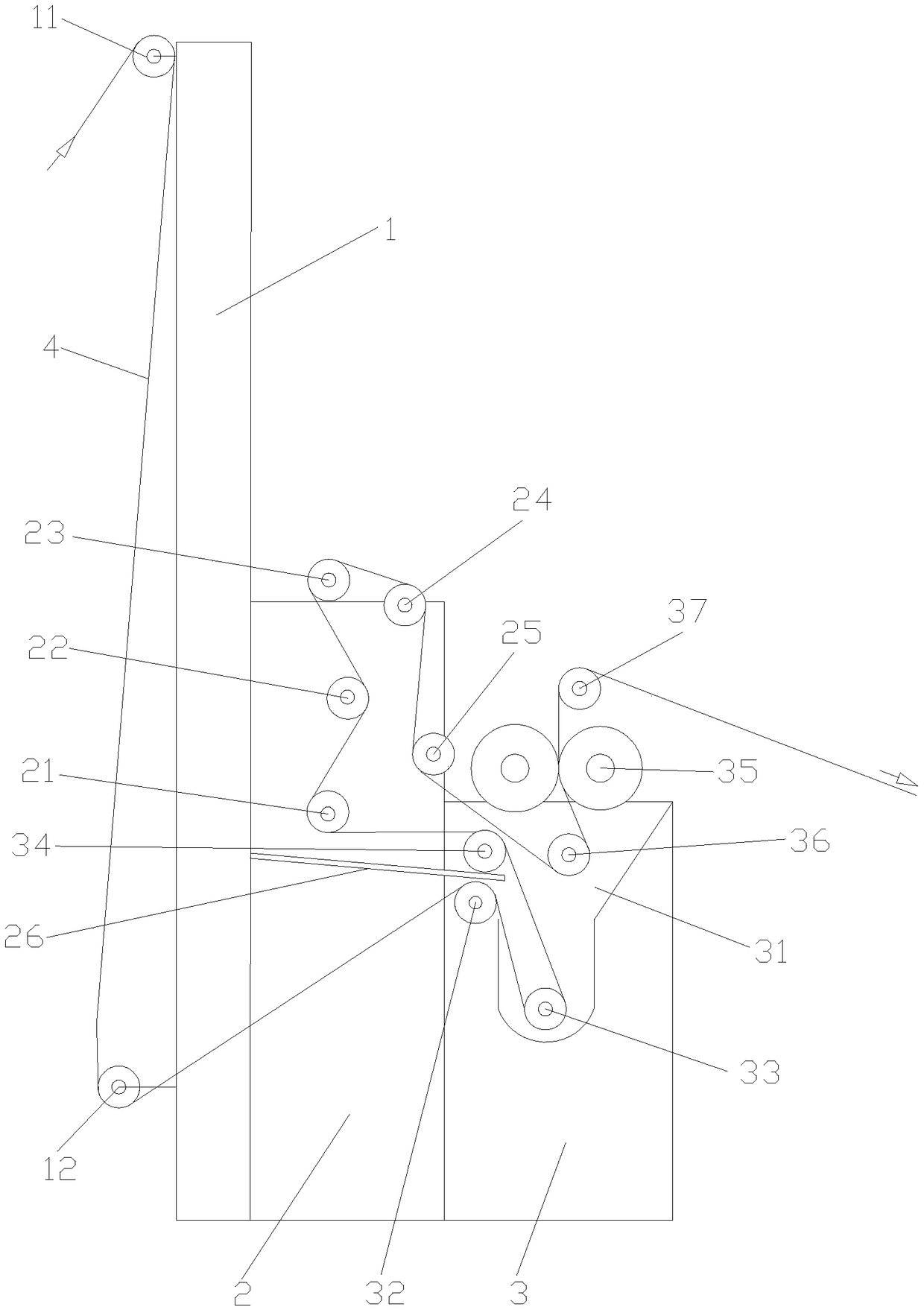

Flame-retardant oriented-structure strand board improved production device and technology

ActiveCN109822711AFully absorbedAvoid wastageCoating impregnationDomestic articlesEngineeringFire retardant

The invention discloses a flame-retardant oriented-structure strand board improved production device and technology. An oriented strand board production system comprises a wet strand board conveying device, a wet strand board stock bin, a drying device, a dry strand board first conveying device, a screening device, a dry strand board stock bin, a dry strand board second conveying device, a glue blending device, a spreading device, a hot pressing device and a flame retardant spraying structure; and the flame retardant spraying structure is connected with the wet strand board conveying device, the dry strand board first conveying device, the dry strand board second conveying device, the glue blending device and the spreading device. According to the flame-retardant oriented-structure strandboard improved production device and technology, multi-procedure spraying is adopted, strand boards can sufficiently absorb a flame retardant, the flame retardant is uniformly distributed, the situation that the spraying quantity of the flame retardant during a single procedure does not reach the standard, thus, the flame retarding performance of the boards are unqualified, or the spraying quantity of the flame retardant is too large, the surfaces of the strand boards cannot absorb the flame retardant in time, and the flame retardant runs off and is wasted is avoided. The flame-retardant oriented strand boards obtained through processing are good in flame retarding performance, and equivalent to oriented strand boards produced and pressed without adding the flame retardant in physical performance.

Owner:湖北宝源木业有限公司

Preparation method of antibacterial quick-drying adhesive used for paper products

InactiveCN105778820AAdhesive fastGood antibacterial effectNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveLimonene oxide

The invention discloses an antibacterial quick-drying adhesive used for paper products and a preparation method thereof. The antibacterial quick-drying adhesive used for paper products is prepared from the following components in parts by weight: 100-150 parts of corn starch, 2-8 parts of oxidant, 2-8 parts of limonene, 1-4 parts of thermal initiator, 1-4 parts of defoaming agent, 1-4 parts of borax, 10-20 parts of sodium bentonite, 4-20 parts of antibacterial agent and 0.2-0.4 part of additive. The adhesive has the beneficial effects that wastes are utilized, thus saving energy, protecting the environment and reducing environmental pollution; the service life of the adhesive is prolonged as a whole; the adhesive has excellent environment friendliness, high safety and outstanding significance.

Owner:JIANGSU JINWO MACHINERY

Straw fiber and bast fiber mixed nonwoven fabric for water-resistant and heat-resistant seamless wallpaper and preparation method of straw fiber and bast fiber mixed nonwoven fabric

InactiveCN105200660AImprove toughnessExtended service lifeSynthetic resin layered productsNon-woven fabricsMethacrylatePolyvinyl alcohol

The invention discloses a straw fiber and bast fiber mixed nonwoven fabric for water-resistant and heat-resistant seamless wallpaper. The straw fiber and bast fiber mixed nonwoven fabric is prepared from the following raw materials in parts by weight: 220-205 parts of straws, 100-104 parts of original hemps, a proper amount of NaOH, a proper amount of water, 0.8-0.85 part of polyvinyl alcohol, 0.5-0.6 part of bamboo charcoal powder, 0.2-0.3 part of trifluoroethyl methacrylate, 0.2-0.3 part of dodecafluoroheptyl methacrylate, 5-6 parts of ethyl acetate, 0.4-0.5 part of 4,4'-diphenylmethane diisocyanate, 0.4-0.5 part of hydroxyl silicon oil, 0.7-0.9 part of a waterborne fluorocarbon emulsion, 0.3-0.4 part of nanometer polytetrafluoroethylene and 0.05-0.1 part of dicumyl peroxide. The nonwoven fabric disclosed by the invention is prepared from 4,4'-diphenylmethane diisocyanate, the hydroxyl silicon oil and the waterborne fluorocarbon emulsion, so that the water resistance, heat resistance and toughness of the nonwoven fabric are improved; and due to the use of the bamboo charcoal powder, the nonwoven fabric has an antibacterial property.

Owner:陈杰

Flexible metal laminate

ActiveUS20140308478A1Low dielectric constantOptimized coefficientDielectric materialsFilm/foil adhesivesPolymer resinPolymer chemistry

Owner:GUANGDONG SHENGYI SCI TECH

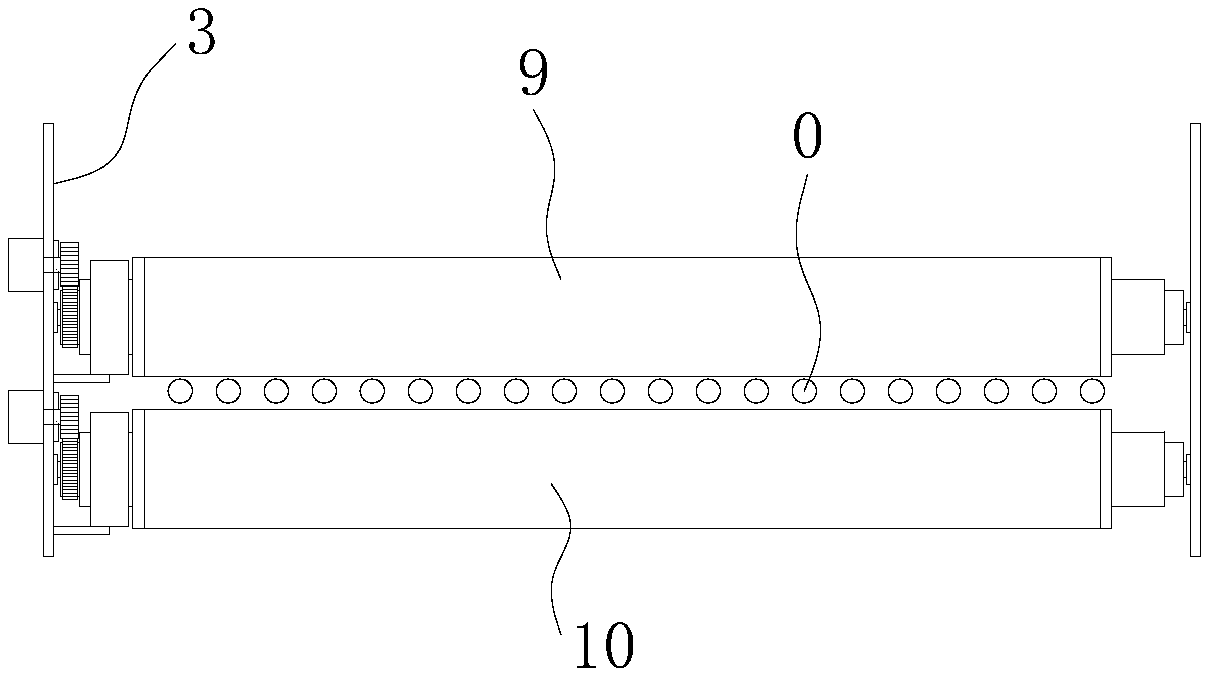

Mercerization of modal or viscose fabric and multi-stage expansion device for mercerization

PendingCN108914464AGood dyeing depthUniform colorSucessive textile treatmentsMercerising of indefinite length fabricsCotton fibreColor changes

The invention discloses mercerization of a modal or viscose fabric. The mercerization of the modal or viscose fabric comprises the following steps: a, bleaching a fabric to obtain a product A; b, soaking and rolling the product A with KOH alkali liquor to obtain a product B; c, carrying out multi-stage expansion on the product B to obtain a product C; d, flatly expanding the product C to obtain aproduct D; e, washing the product D to obtain a product E; f, neutralizing the product E with acid to obtain a product F; g, washing the product F to obtain a product G; and h, drying the product G toobtain a finished product. In the step b, the product A is soaked and rolled repeatedly with the KOH alkali liquor to obtain the product B; and the KOH alkali liquor container KOH with the mass concentration being 20%-24%. The mercerization of the modal or viscose fabric has the advantages that a modal or viscose and cotton fiber blended and interlaced fabric is mercerized, thus, the modal or viscose and cotton fiber blended and interlaced fabric does not have flash on a fabric surface, color change of the fabric is weak after the fabric is washed, and the color of the fabric is unlikely to fade, and the strength of the viscose-containing fabric can further be improved.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

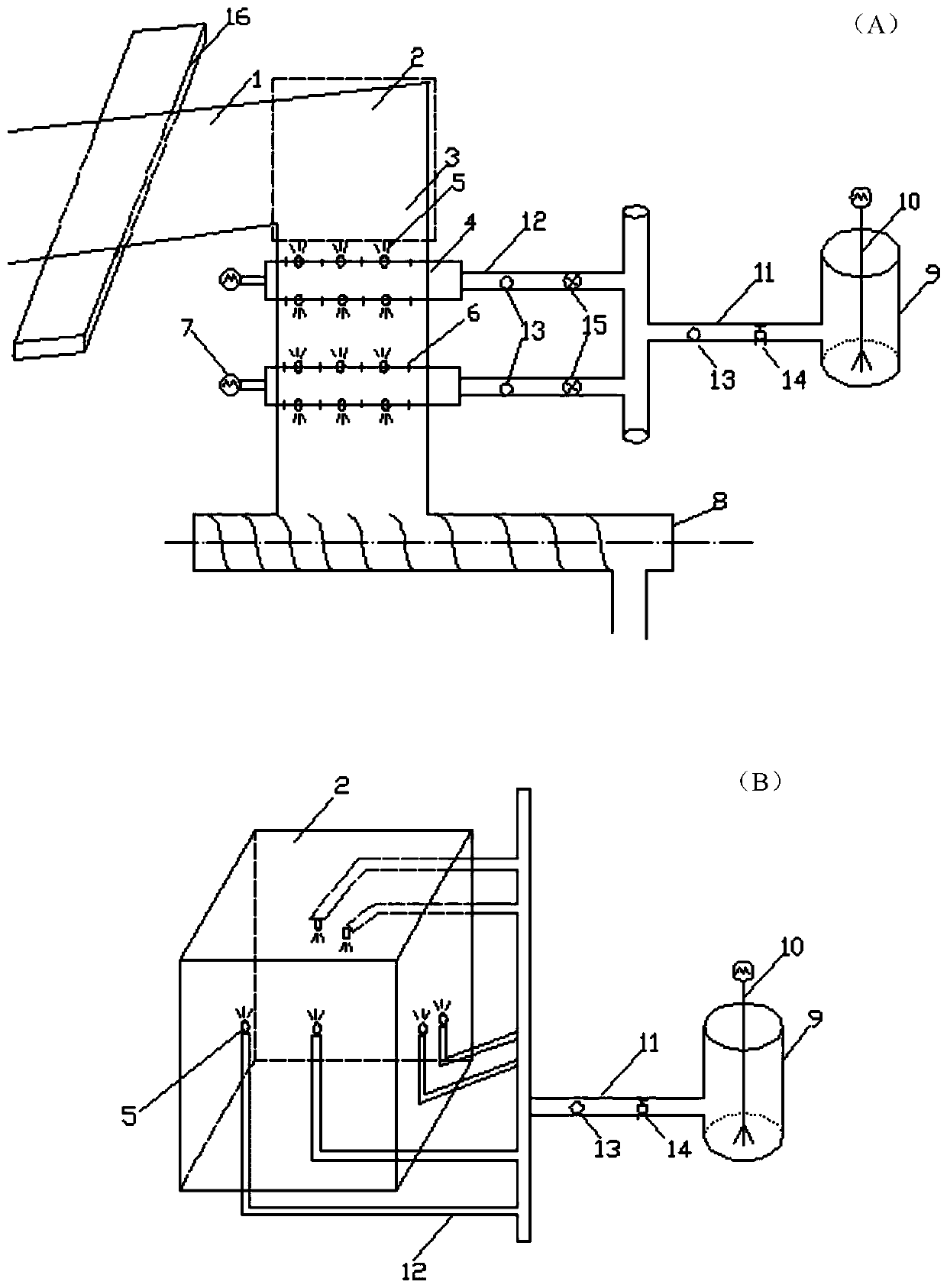

Multi-section flame retardant adding type production system and method for improving flame retarding performance of directional shaving board

ActiveCN109773935AFully absorbedAvoid wastageDomestic articlesFlat articlesEngineeringFire retardant

The invention discloses a multi-section flame retardant adding type production system and method for improving flame retarding performance of directional shaving board. The system comprises a wet shaving material bin, a second wet shaving sheet conveying device, a drying device, a first dry shaving sheet conveying device, a screening device, a dry shaving sheet bin, a second dry shaving sheet conveying device, a gum mixing device, a paving device, a thermal pressing device, a post-treatment device for acting after thermal pressing, and a flame retardant spraying structure, wherein the flame retardant spraying structure is connected to the second wet shaving sheet conveying device, the first dry shaving sheet conveying device and / or the second dry shaving sheet conveying device, the gum mixing device, the paving device and / or the thermal pressing device. According to the system and the method, multi-process spraying is carried out, so that shaving sheets can fully absorb; the flame retardant is uniformly distributed, and the problems that the flame retarding performance of a board is low or the flame retardant is excessively sprayed, the surface of shavings cannot absorb timely, and the flame retardant is lost, can be avoided; the processed flame retarding shaving board is outstanding in flame retarding performance; and the physical performance is equal to that of a shaving board produced by pressed without the flame retardant.

Owner:湖北宝源木业有限公司

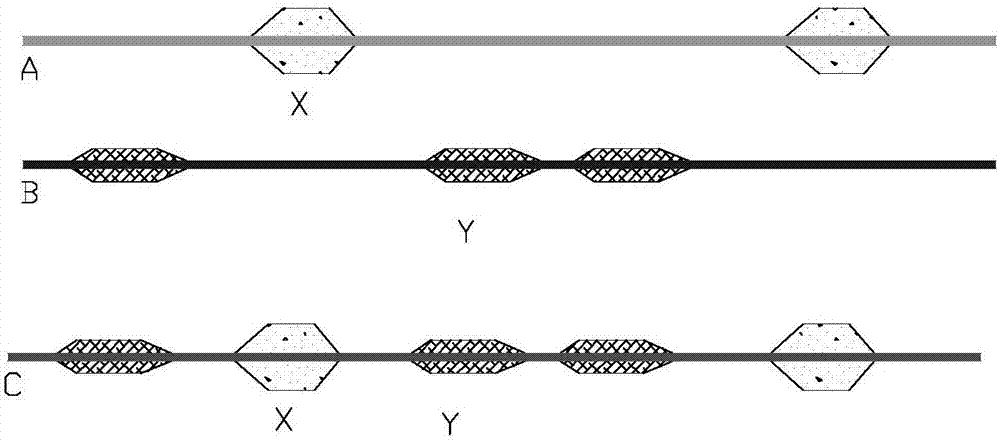

Polyester linen-like yarn, preparation method thereof and fabric prepared from yarn

ActiveCN112376141AHigh fiber strengthLow moisture regainSevering to form staple fibresTextile disintegration and recoveryPolyesterYarn

The invention belongs to the technical field of spinning, and relates to preparation of pure polyester linen-like yarns and pure polyester linen-like fabrics. According to the unique style characteristics of non-uniform yarn levelness and random bamboo joints of linen fabrics,by adopting polyester staple fibers with high fiber strength, low moisture regain, washability, durability and equal length, through a special artificial cutting pretreatment mode, by studying the process optimization of spinning and weaving, yarns of a linen style are spun. The appearance form and the hand feeling of theprepared yarn are extremely similar to those of traditional linen yarn, corresponding linen-like cloth is woven through a rapier loom, and the linen-like cloth replaces pure linen fabric on the market.

Owner:宁波涵洋纺织科技有限公司

A treatment method for moldy nylon printed carpet

ActiveCN103726292BClean up thoroughlyNon-irritatingDry-cleaning apparatus for textilesPulp and paper industrySlurry

The invention belongs to the technical field of carpet treatment, and particularly relates to a treatment method of a moldy nylon printed carpet. The treatment method of a moldy nylon printed carpet comprises the following steps: (1) mixing of slurry; (2) slurry spraying; (3) heating; (4) washing; (5) vacuum water absorption; (6) drying. The method can be used for thoroughly clearing moldy spots and is simple and low in cost.

Owner:BINZHOU COC CARPET

A kind of high-performance moisture-proof paper and its preparation method and application

ActiveCN105648835BHigh strengthImprove waterproof performancePaper coatingReinforcing agents additionEpoxyPolyvinyl alcohol

The invention belongs to the technical field of preparation of special paper, and particularly relates to high-performance moisture-proof paper and a preparation method and an application thereof. The preparation method comprises the following steps: using an alkyl ketene dimmer as an adhesive in an amount of 2-8 percent based on the absolute dry mass of paper pulp; using polyamide amine epoxy chloropropane as an enhancer in an amount of 0-5 percent based on the absolute dry mass of the paper pulp to perform internal sizing; preparing a polyvinyl alcohol solution, adding styrene acrylic ester in an amount of 10-15 percent based on the mass of the polyvinyl alcohol and vinyl acetate-ethylene copolymer emulsion in an amount of 30-50 percent based on the mass of the polyvinyl alcohol, mixing, and adding the adhesive and the enhancer to prepare a sizing material; sizing the prepared sizing material on the surface of a paper machine through a sizing material to obtain the high-performance moisture-proof paper. The moisture-proof paper prepared through the method has high waterproofness and oil resistance, and the moisture regain is lower than 5 percent after standing at a high temperature of 40 DEG C and at high humidity of 95 percent for 24 hours.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com