Multi-section flame retardant adding type production system and method for improving flame retarding performance of directional shaving board

A production system and flame retardant technology, applied in the field of wood processing, can solve problems such as application limitations, flame retardant performance that cannot meet safety requirements, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

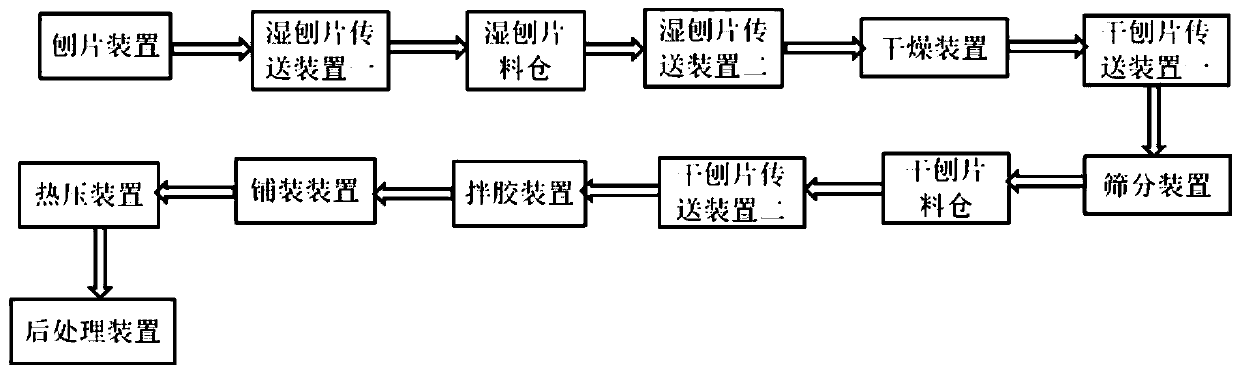

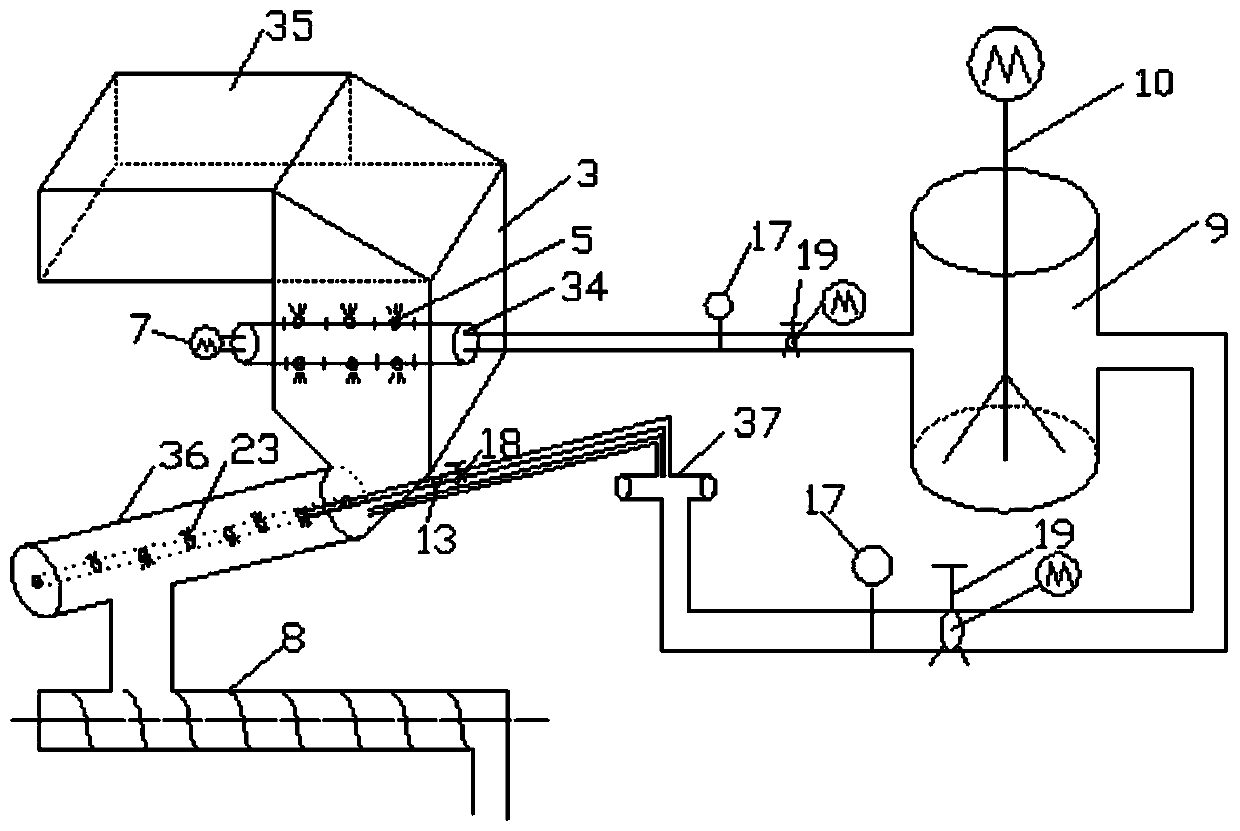

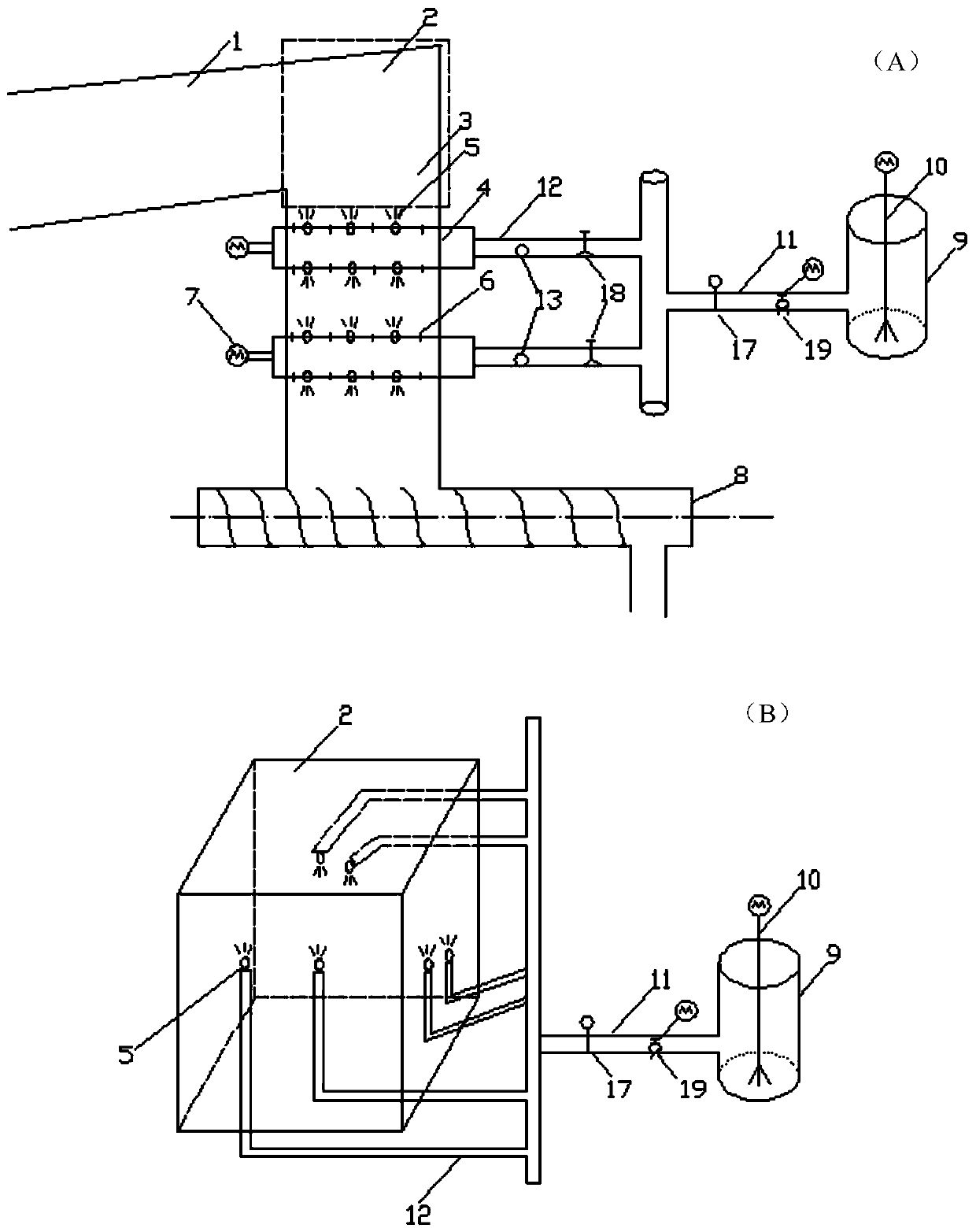

[0101] Such as figure 1 The production system for adding flame retardants to improve the flame retardancy of oriented strand board is shown in the multi-stage production system. The production system includes: flaking device, wet flaking conveying device 1, wet flaking silo, wet flaking conveying device 2, drying device , Dry flaking conveying device 1, screening device, dry flaking silo, dry flaking conveying device 2, glue mixing device, paving device, hot pressing device, post-processing device after hot pressing and flame retardant spraying structure ;

[0102]Flame retardant spraying structure 1 is connected with wet flaking conveying device 2, flame retardant spraying structure 2 is connected with dry flaking conveying device 1 and / or dry flaking conveying device 2, flame retardant spraying structure 3 is connected with glue mixing The devices are connected, and the flame retardant spraying structure 4 is connected with the paving device. The wet shaving conveying devi...

Embodiment 2

[0133] Planer specifications: width 5-40mm, thickness 0.4-0.8mm, length 100-180mm.

[0134] Adopt the production system of embodiment 1, promote the method for oriented strand board flame retardancy, this method comprises the steps:

[0135] (1) The shavings conveyed from the wet shaving silo, spray the flame retardant solution A on the wet shavings during the blanking process and the stirring process of the atomizing cylinder (the temperature of the flame retardant solution A is 25±5°C ), sent to dry;

[0136] (2) Step (1) After the shavings sprayed with flame retardant A are dried, before entering the dry shaving silo, spray flame retardant solution A on the falling dry shavings in the blanking channel and the blanking port ; After spraying the flame retardant, the shavings enter the dry shaving silo, and the dry shavings conveyed from the dry shaving silo enter the glue mixing process;

[0137] The temperature of flame retardant solution A is 25±5°C;

[0138] Feed rate a...

Embodiment 3

[0146] Embodiment 3 is the same as that of Embodiment 2, wherein the amount of fire retardant sprayed (i.e. the pump flow rate), the concentration of fire retardant, and the water content of the flakes before and after spraying the flame retardant, the amount of flame retardant attached, and each The test results of the flame retardancy of the shavings in the process are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com