Integrated seed cotton vacuum drying and cleaning processing system and operating method thereof

A vacuum drying and processing system technology, applied in mechanical processing, fiber processing, dryer combination, etc., can solve problems such as long distance of hot air delivery, large footprint of heating and drying equipment, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

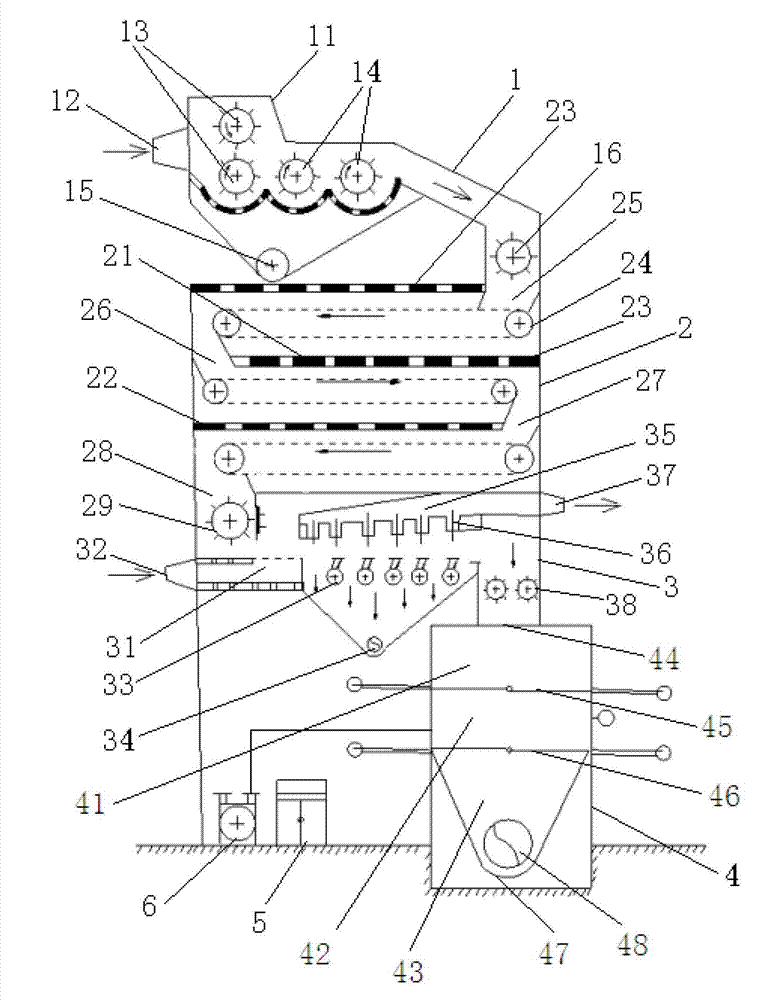

[0023] The seed cotton separator 1 of the present invention comprises a separator housing 11, a separator housing inlet 12 is arranged on the separator housing 11, and a fan for conveying seed cotton to the separator housing inlet 12 is arranged outside the separator housing 11 (Fig. not shown in ), a pair of opening rollers 13 that rotate in opposite directions are arranged in the separator casing 11 at the inlet 12 of the separator casing, and a number of spike rollers 14 are arranged in the separator casing 11 behind the opening rollers 13 (Two spike rollers 14 are set in this embodiment), the separator housing 11 below the spike rollers 14 is provided with a suction pipe 15 connected to the fan; the separator casing 11 behind the spike rollers 14 is downward Slope-like, the separator housing 11 is provided with a separator housing outlet below the slope, and a first seed cotton pulling roller 16 is arranged at the separator housing outlet.

[0024] The electric heating box...

Embodiment 2

[0053]The seed cotton separator 1 of the present invention comprises a separator housing 11, a separator housing inlet 12 is arranged on the separator housing 11, and a fan for conveying seed cotton to the separator housing inlet 12 is arranged outside the separator housing 11 (Fig. not shown in ), a pair of opening rollers 13 that rotate in opposite directions are arranged in the separator casing 11 at the inlet 12 of the separator casing, and a number of spike rollers 14 are arranged in the separator casing 11 behind the opening rollers 13 (Two spike rollers 14 are set in this embodiment), the separator housing 11 below the spike rollers 14 is provided with a suction pipe 15 connected to the fan; the separator casing 11 behind the spike rollers 14 is downward Slope-like, the separator housing 11 is provided with a separator housing outlet below the slope, and a first seed cotton pulling roller 16 is arranged at the separator housing outlet.

[0054] The electric heating box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com