Anticorrosive rubber lining and preparation method thereof

A technology of anti-corrosion rubber and special rubber, applied in the field of rubber lining, can solve the problems of loose fit, lining falling off, high water absorption, and achieve the effects of good fit, high structural stability and low moisture regain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

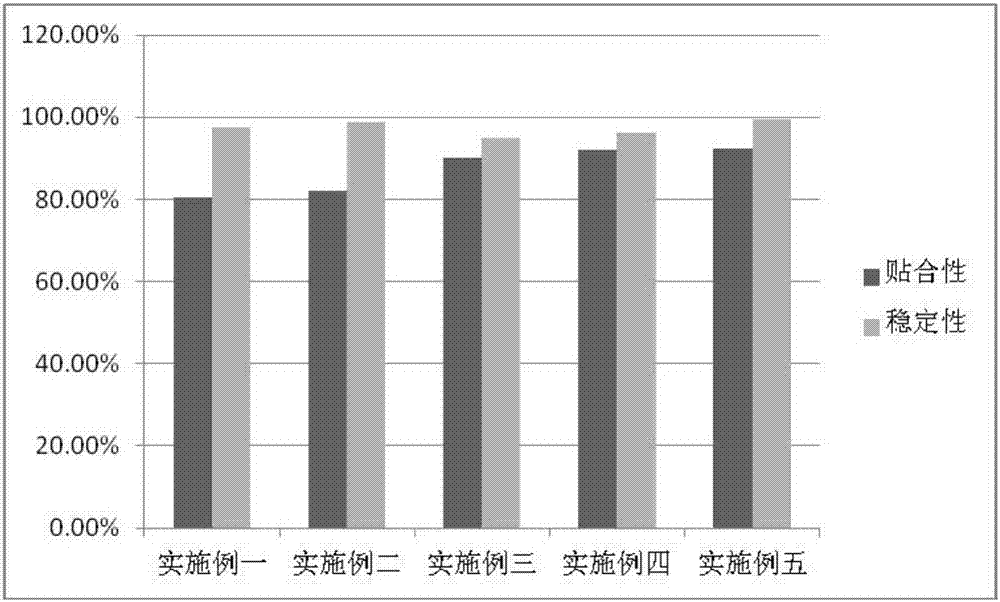

Examples

Embodiment 1

[0032] A kind of preparation method of anticorrosion rubber lining that the present invention proposes, comprises the following steps:

[0033] S1. Add the natural rubber, special rubber, thermoplastic rubber and peptizer of formula quantity in the internal mixer, masticate 20min under the condition of 50 ℃ to become plastic glue A;

[0034] S2. Add high-volume styrene, graphite powder, sulfur, high-speed accelerator and dispersant to plasticizing rubber A in S1, and knead in an internal mixer for 15 minutes at 70°C to form rubber mixing B ;

[0035] In S3.S2, the mixed rubber B is kneaded in the open mill, made into triangular bags 3 times, and then filtered into the filter;

[0036] S4. Add the braided fabric of the formula amount to the mixed rubber after filtering the mixed rubber B in S3 and put it into the open mill for the second milling to form the mixed rubber C;

[0037] S5. Carry out the third milling of the mixed rubber C in S4 on the open mill to form the mixed ...

Embodiment 2

[0043] A kind of preparation method of anticorrosion rubber lining that the present invention proposes, comprises the following steps:

[0044] S1. Add the natural rubber, special rubber, thermoplastic rubber and peptizer of formula quantity in the internal mixer, masticate 20min under the condition of 60 ℃ to become plastic glue A;

[0045] S2. Add high-volume styrene, graphite powder, sulfur, high-speed accelerator and dispersant to plasticizing rubber A in S1, and knead in an internal mixer for 15 minutes at 80°C to form rubber mixing B ;

[0046] In S3.S2, the mixed rubber B is kneaded in the open mill, made into triangular bags 3 times, and then filtered into the filter;

[0047] S4. Add the braided fabric of the formula amount to the mixed rubber after filtering the mixed rubber B in S3 and put it into the open mill for the second milling to form the mixed rubber C;

[0048] S5. Carry out the third milling of the mixed rubber C in S4 on the open mill to form the mixed ...

Embodiment 3

[0054] A kind of preparation method of anticorrosion rubber lining that the present invention proposes, comprises the following steps:

[0055] S1. Add the natural rubber, special rubber, thermoplastic rubber and peptizer of formula quantity in the internal mixer, masticate 30min under the condition of 70 ℃ to become plastic glue A;

[0056] S2. Add high-quality styrene, graphite powder, sulfur, high-speed accelerator and dispersant to the plasticizing rubber A in S1, and knead in an internal mixer for 15 minutes at 80°C to form rubber mixing B ;

[0057] In S3.S2, the mixed rubber B is kneaded in the open mill, made into triangular bags 3 times, and then filtered into the filter;

[0058] S4. Add the braided fabric of the formula amount to the mixed rubber after filtering the mixed rubber B in S3 and put it into the open mill for the second milling to form the mixed rubber C;

[0059] S5. Carry out the third milling of the mixed rubber C in S4 on the open mill to form the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com