Antiseptic rubber lining and preparation method thereof

A technology of anti-corrosion rubber and styrene-butadiene rubber, which is applied in the field of chemical anti-corrosion materials, can solve the problems that the anti-corrosion performance cannot meet the requirements, and achieve the effect of solving the problem of anti-corrosion performance, easy to realize, and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

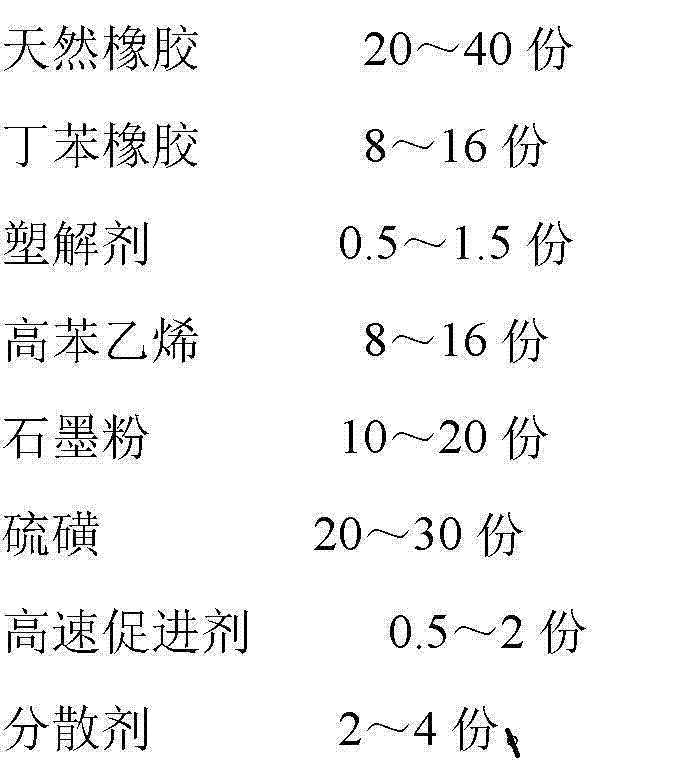

[0021] A kind of anticorrosion rubber lining, comprises the component of following parts by weight:

[0022]

[0023] The production method is as follows:

[0024] (1) Add the No. 1 standard rubber, 1502-type styrene-butadiene rubber and peptizer Struktol A82 into the internal mixer, and masticate for 12 minutes at 60°C to form plastic rubber;

[0025] (2) Add high styrene, graphite powder, sulfur, TMTM promotor and dispersant in the above-mentioned masticated rubber, and knead in the internal mixer for 15 minutes at 80° C. to form a mixed rubber;

[0026] (3) above-mentioned mixed rubber is carried out refining in open mill, makes triangular bag 4 times, enters filter machine to filter then;

[0027] (4) Carry out the second milling of the above-mentioned filtered mixed rubber on the open mill, cut into strips and enter the film cooler to cool to 30°C for storage and wait for extrusion;

[0028] (5) Extrude the stored film into an extruder.

Embodiment 2

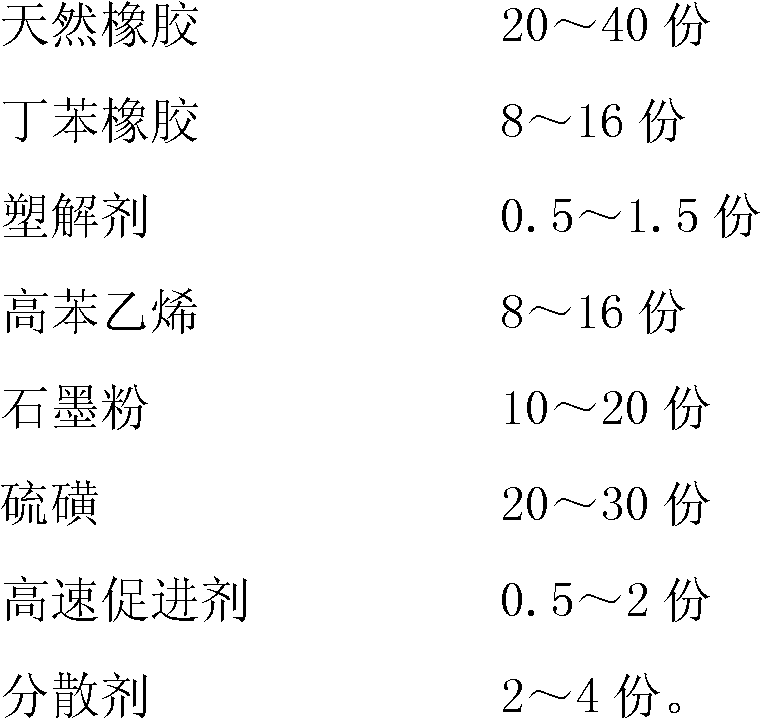

[0030] A kind of anticorrosion rubber lining, comprises the component of following parts by weight:

[0031]

[0032] The production method is as follows:

[0033] (1) Add the No. 1 standard rubber, 1502-type styrene-butadiene rubber and peptizer Struktol A82 into the internal mixer, and masticate for 10 minutes at 80°C to form plastic rubber;

[0034] (2) Add high styrene, graphite powder, sulfur, TMTM accelerant and dispersing agent of formulation amount to above-mentioned masticated rubber, under the condition of 65 ℃, knead in described internal mixer for 10min to form mixed rubber;

[0035] (3) The above-mentioned mixed rubber is carried out in an open mill, and the triangular bag is made 3 times, and then enters the filter to filter;

[0036] (4) Carry out the second milling of the above-mentioned filtered mixed rubber on the open mill, cut into strips and enter the film cooler to cool to 28 ° C for storage, waiting for extrusion;

[0037] (5) Extrude the stored fil...

Embodiment 3

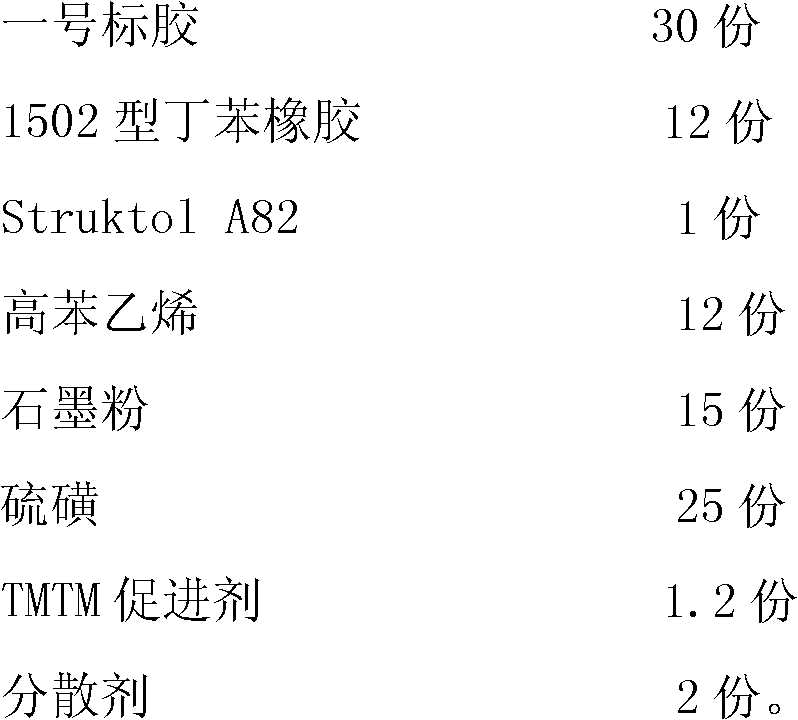

[0039] A kind of anticorrosion rubber lining, comprises the component of following parts by weight:

[0040]

[0041]

[0042] The production method is as follows:

[0043] (1) Add the No. 1 standard rubber, 1502-type styrene-butadiene rubber and peptizer Struktol A82 into the internal mixer, and masticate for 15 minutes at 70°C to form plastic rubber;

[0044] (2) Add high styrene, graphite powder, sulfur, TMTM accelerator and dispersant in the above-mentioned masticated rubber, and knead in the internal mixer for 12 minutes at 50° C. to form a mixed rubber;

[0045] (3) above-mentioned mixed rubber is carried out refining in open mill, makes triangular bag 5 times, enters filter machine to filter then;

[0046] (4) Carry out the second milling of the above-mentioned filtered mixed rubber on the open mill, cut into strips and enter the film cooler to cool to 30°C for storage and wait for extrusion;

[0047] (6) Extrude the stored film into an extruder.

[0048] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com