Mercerization of modal or viscose fabric and multi-stage expansion device for mercerization

A spreading device and fabric technology, which is applied in the processing of textile materials, mercerizing of indefinite length fabrics, continuous processing of textile materials, etc., can solve the problems of large demand for impregnating liquid, insufficient impregnation permeability and uniformity of fabrics, and changes in shrinkage rate Large and other problems, to achieve the effect of improving the instability of shrinkage rate, improving the effect of dyeing depth, and reducing the moisture regain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1. Mercerizing of modal or viscose fabrics, including the following steps:

[0033] a, bleached fabric, get A product; Described fabric is the fabric that modal and cotton fiber blend interweave;

[0034] b. Use KOH lye to soak and roll product A more than once to obtain product B; the KOH lye contains KOH with a mass concentration of 22% and 6.5g / L mercerizing penetrant. The model of mercerizing penetrant is MXD-T, iso Tridecyl alcohol polyoxyethylene ether phosphate;

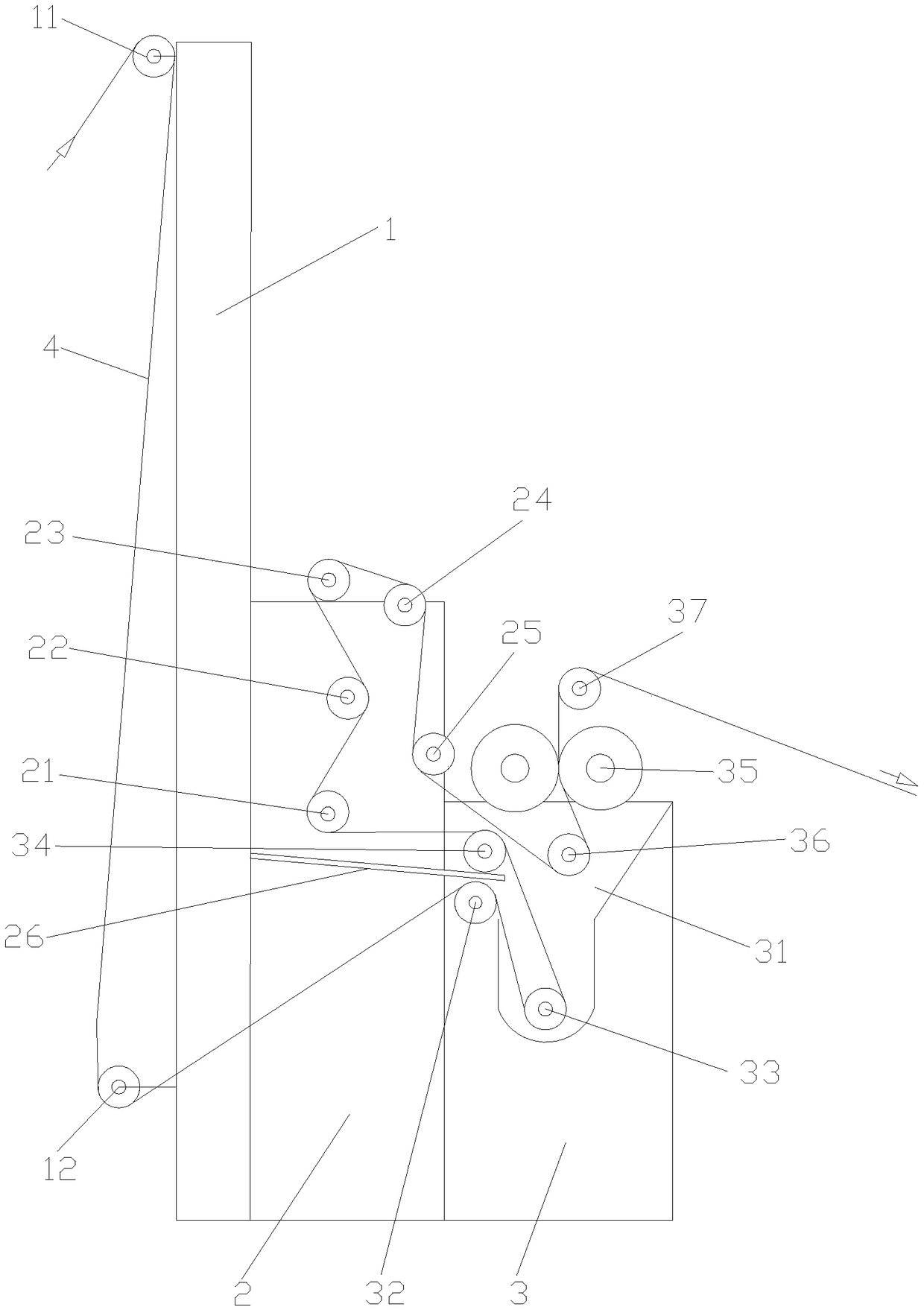

[0035] c. Using a multi-stage amplification device to perform multi-stage amplification on product B to obtain product C;

[0036] d. Use a tight open-width expanding device to flatten and expand product C to obtain product D;

[0037] e. Wash product D with water to obtain product E;

[0038] f. Neutralize product E with acid to obtain product F;

[0039] g. Wash product F with water to obtain product G;

[0040] h, drying product G to obtain a finished product.

[0041] The resulting fi...

Embodiment 2

[0042] Example 2. Mercerizing of modal or viscose fabrics, including the following steps:

[0043] A, bleached fabric, get A product; Described fabric is the fabric that viscose and cotton fiber blend interweave;

[0044] b. Use KOH lye to soak and roll product A more than once to obtain product B; the KOH lye contains KOH with a mass concentration of 20% and 5g / L mercerizing penetrant. The model of mercerizing penetrant is MXD-T, isomerism Tridecyl alcohol polyoxyethylene ether phosphate;

[0045] c. Using a multi-stage amplification device to perform multi-stage amplification on product B to obtain product C;

[0046] d. Use a tight open-width expanding device to flatten and expand product C to obtain product D;

[0047] e. Wash product D with water to obtain product E;

[0048] f. Neutralize product E with acid to obtain product F;

[0049] g. Wash product F with water to obtain product G;

[0050] h, drying product G to obtain a finished product.

[0051] The result...

Embodiment 3

[0052] Example 3. Mercerizing of modal or viscose fabrics, including the following steps:

[0053] a, bleached fabrics, get A product; said fabrics are pure modal fabrics;

[0054] b. Use KOH lye to soak and roll product A more than once to obtain product B; the KOH lye contains KOH with a mass concentration of 24% and mercerized penetrant of 8 g / L. The type of mercerized penetrant is MXD-T, isomerism Tridecyl alcohol polyoxyethylene ether phosphate;

[0055] c. Using a multi-stage amplification device to perform multi-stage amplification on product B to obtain product C;

[0056] d. Use a tight open-width expanding device to flatten and expand product C to obtain product D;

[0057] e. Wash product D with water to obtain product E;

[0058] f. Neutralize product E with acid to obtain product F;

[0059] g. Wash product F with water to obtain product G;

[0060] h, drying product G to obtain a finished product.

[0061] The fabric shrinkage rate of the finished product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com