Application of dye in dyeing of nylon cotton fabrics

A dye and nylon-cotton technology is applied in the application field of dyestuffs in the dyeing of nylon-cotton fabrics, which can solve the problems such as the use of many auxiliaries, the discharge of sewage, and the long production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Weigh 63 grams of component A1, 27 grams of component B3, 8 grams of sodium sulfate and 2 grams of dispersant MF, and blend these powders to obtain the dye described in the present invention.

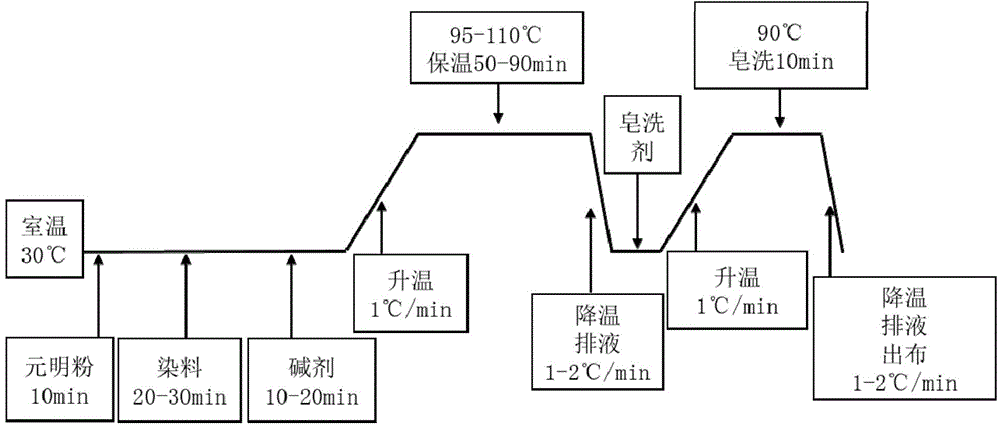

[0097] Take by weighing 10 grams of nylon-cotton interwoven cloth (fiber type and content: 44% nylon 6, 56% cotton fiber, the percentage is the mass percentage of each component quality accounting for the total mass of nylon-cotton interwoven cloth) and the dyestuff of the present embodiment of 0.8 gram . The dyeing bath ratio is 1:10. according to figure 1 implementation of the dyeing process, figure 1 The consumption of Yuanming powder in is added according to the consumption in table 5, 100g in every liter of dyeing liquor. figure 1 Soda ash is selected as the medium alkali agent, and the amount of soda ash is 2g per liter of dyeing liquor. figure 1The soaping agent in the soaping agent is selected Anokosekrui NC, and the consumption amount of the soaping agent is 1g in ev...

Embodiment 2

[0099] Weigh 58 grams of A2 component, 5 grams of compound of formula 5, 27 grams of B2 component, 8 grams of sodium sulfate and 2 grams of dispersant MF, and blend these powders to obtain the dye described in the present invention.

[0100] Take by weighing 10 grams of nylon-cotton interwoven cloth (fiber type and content: 44% nylon 6, 56% cotton fiber, the percentage is the mass percentage of each component quality accounting for the total mass of nylon-cotton interwoven cloth) and the dyestuff of the present embodiment of 0.8 gram , dye bath ratio 1:10, press figure 1 implementation of the dyeing process, figure 1 The consumption of Yuanming powder in is added according to the consumption in table 5, is 100g in every liter of dye liquor. figure 1 Soda ash is selected as the medium alkali agent, and the amount of soda ash is 2g per liter of dyeing liquor. figure 1 The soaping agent in the soaping agent is selected Anokosekrui NC, and the consumption amount of the soaping a...

Embodiment 3

[0102] Weigh 59 grams of component A6, 5 grams of compound of formula three, 22 grams of component B3, 4 grams of compound of formula four, 8 grams of sodium sulfate and 2 grams of dispersant MF, and blend these powders to obtain the compound of the present invention. dye.

[0103] Take by weighing 10 grams of nylon-cotton interwoven cloth (fiber type and content: 41% nylon 6, 6% 40DSP, 53% cotton fiber, percentage is the mass percent that each component quality accounts for nylon-cotton interwoven cloth gross mass, and described 40DSP is Thickness is the spandex of 40 deniers, and its trade mark is spandex.) and the dyestuff of the present embodiment of 0.8 gram, dyeing bath ratio 1:10, press figure 1 implementation of the dyeing process, figure 1 The consumption of Yuanming powder in is added according to the consumption in table 5, is 100g in every liter of dye liquor. figure 1 Soda ash is selected as the medium alkali agent, and the amount of soda ash is 2g per liter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com