Continuous cloth printing and dyeing production line and printing and dyeing production technology thereof

A production line and fabric technology, applied in the field of continuous fabric printing and dyeing production line and its printing and dyeing production process, can solve the problems of uneven chemical slurry, increase energy consumption, addition of printing and dyeing production lines, etc., to improve dyeing effect, improve desizing treatment, improve The effect of tint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

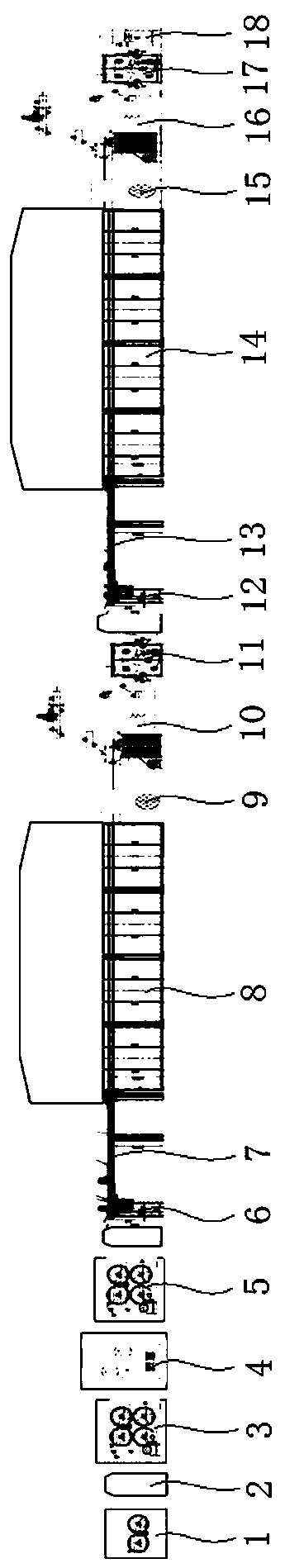

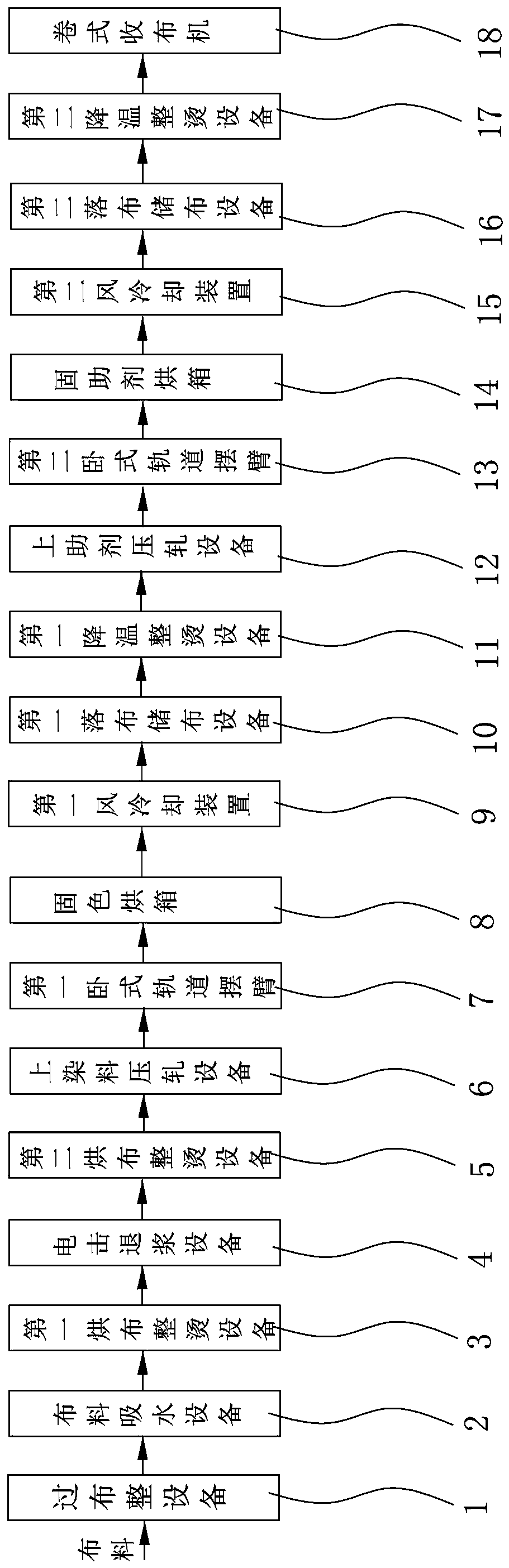

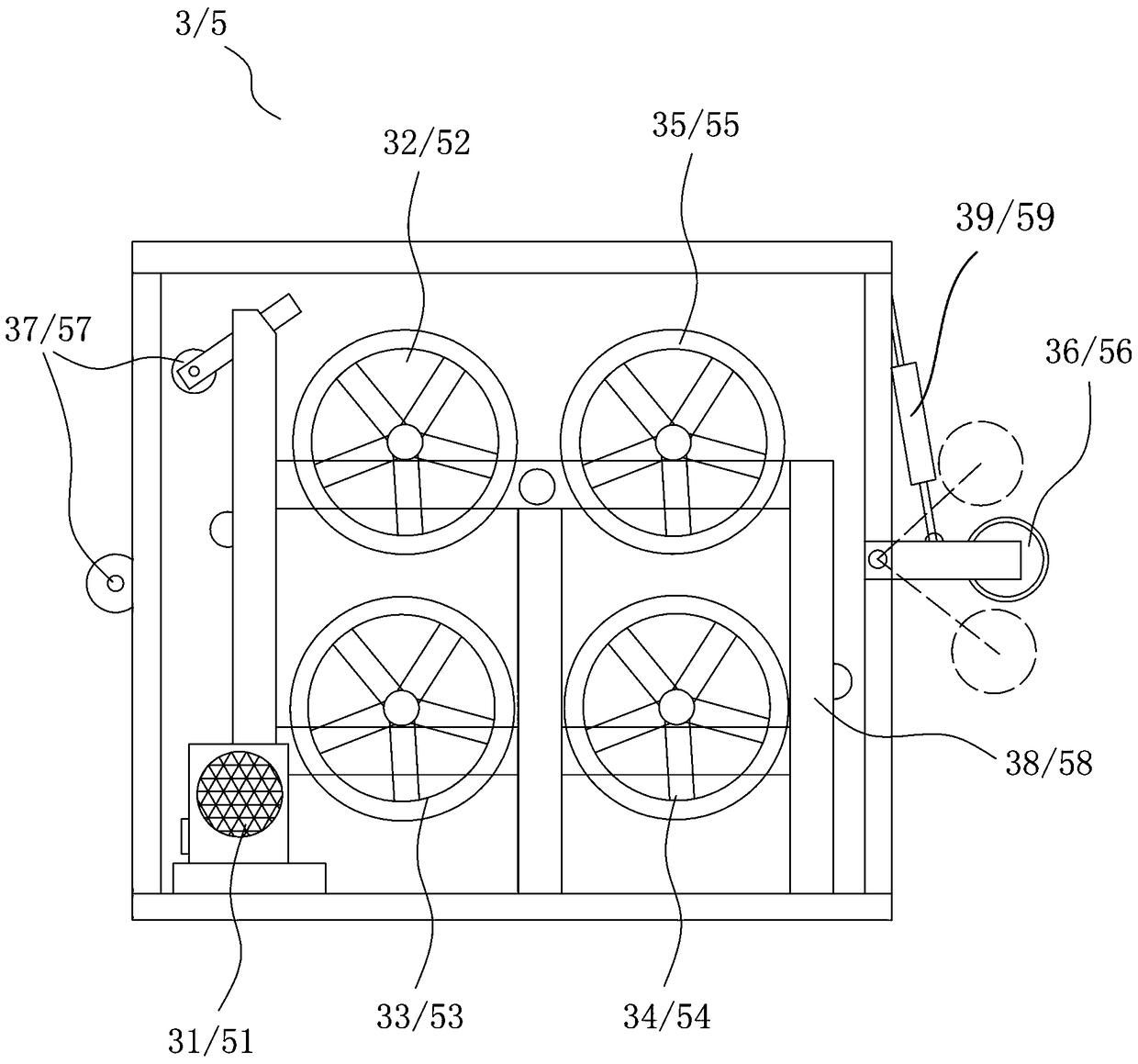

[0037] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] Such as Figure 1-Figure 9 As shown, the present invention is a continuous cloth printing and dyeing production line. Along the continuous cloth printing and dyeing production line, cloth leveling equipment 1, cloth water absorption equipment 2, first cloth drying and ironing equipment 3, electric shock desizing equipment 4, and second Second cloth drying and ironing equipment 5, upper dye pressing equipment 6, first horizontal track swing arm 7, color fixing oven 8, first air cooling device 9, first cloth falling and storage equipment 10, first cooling and ironing Equipment 11, auxiliary agent rolling equipment 12, second horizontal track swing arm 13, solid auxiliary agent oven 14, second air cooling device 15, second cloth falling and storage equipment 16, second cooling and ironing equipment 17 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com