Cotton cloth dyeing device

A dyeing device and cotton cloth technology, which can be used in textiles and papermaking, spray/jet textile material treatment, liquid/gas/steam removal by suction method, etc. It can solve the problems of waste of dyeing agent, inconvenient drying, and excessive amount of dyeing agent , to achieve the effect of solving the waste of pigment and improving the dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

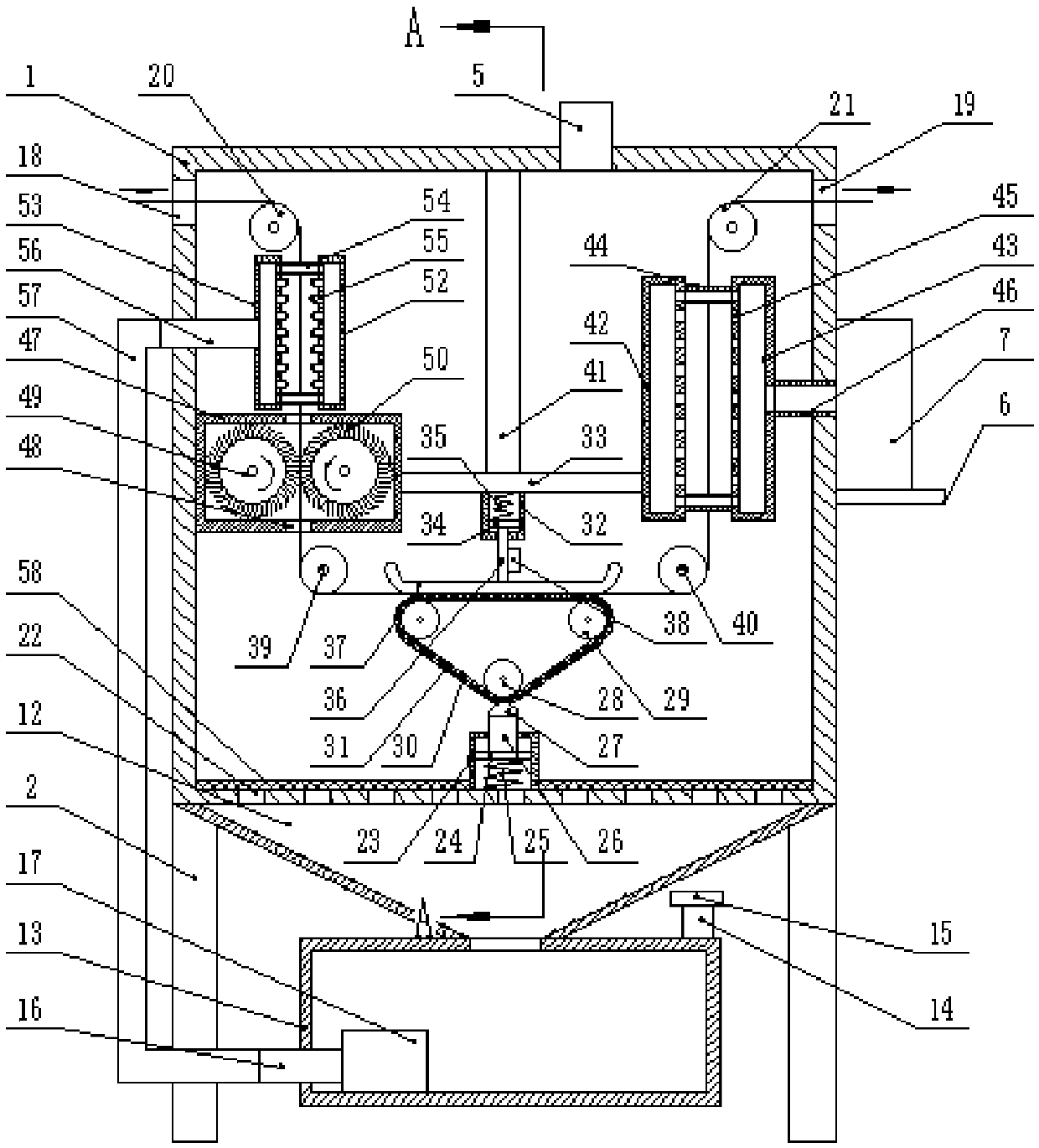

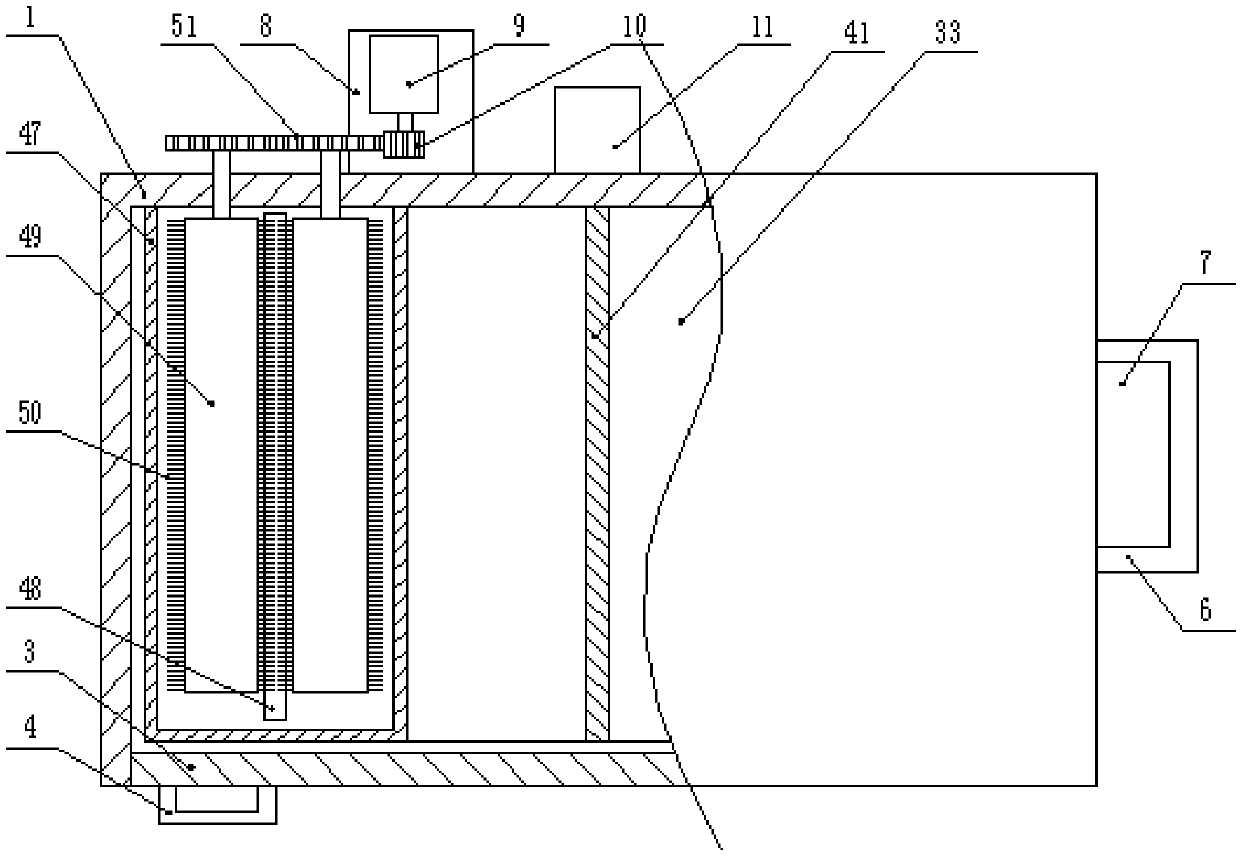

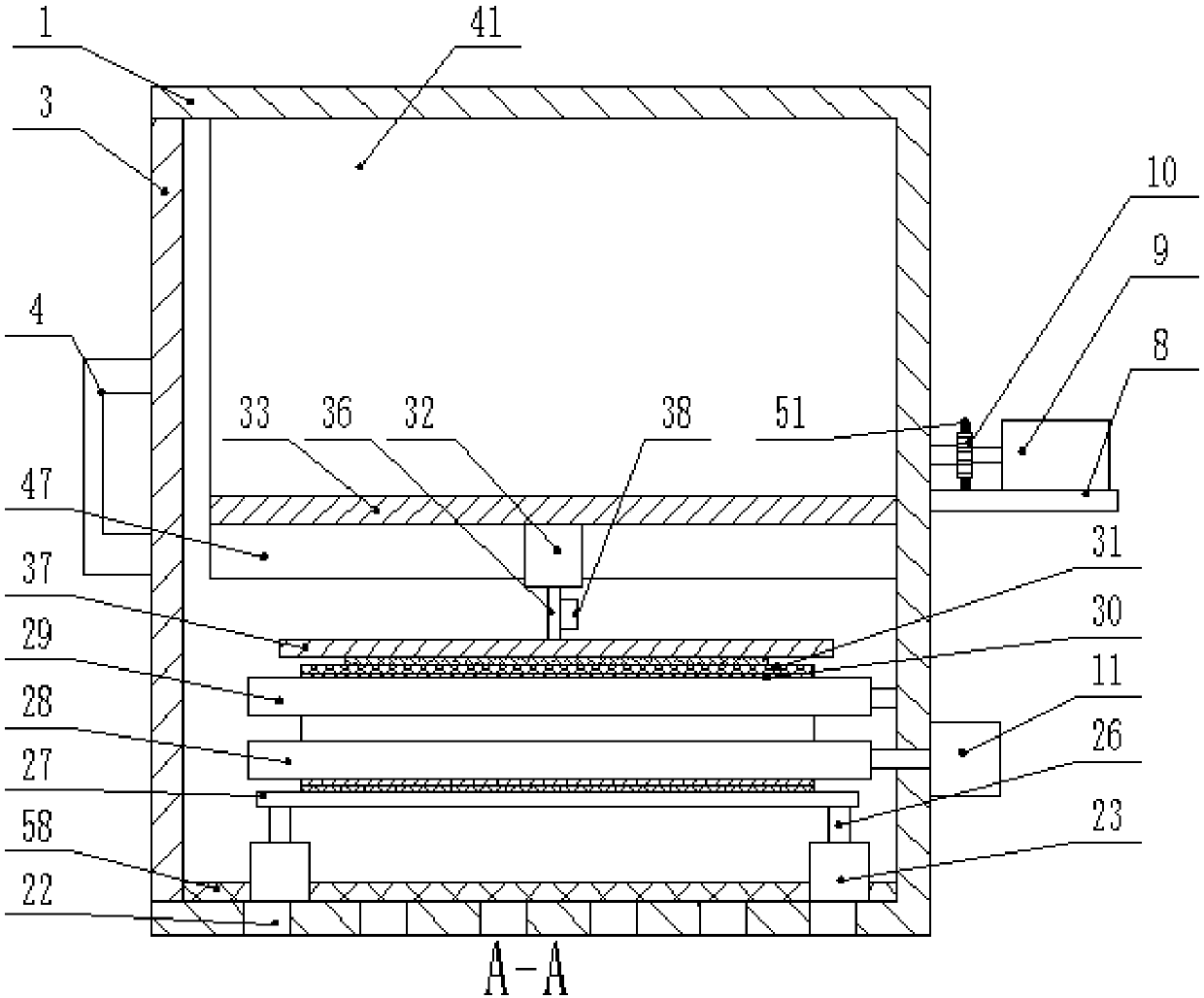

[0014] Such as figure 1 , figure 2As shown, a cotton dyeing device includes a box body 1, and four corners of the bottom end of the box body 1 are respectively fixed with support rods 2, and a box door 3 is hinged on one side of the box body 1, and a box door 3 is fixed on the box body 1. A handle 4 is provided, and an exhaust pipe 5 is fixed on the top of the box body 1, and the exhaust pipe 5 communicates with the inside of the box body 1, and a fixed plate 6 is fixed on the side wall of the box body 1, and the fixed plate 6 is fixed with a hot air blower 7, a first fixed plate 8 is fixed on the opposite side wall of the box door 3 on the box body 1, and a motor 9 is fixed on the top surface of the first fixed plate 8, and the motor 9 is fixed on the top surface of the first fixed plate 8. 9. A gear 10 is fixed on the output end, and a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com