Wet cloth vacuum dewatering machine

A technology of vacuum dehydration and wet cloth, which is applied in the direction of removing liquid/gas/vapor by suction method, can solve the problem of unsuitable continuous operation of cloth production, and achieve the effect of good dehydration effect and low equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

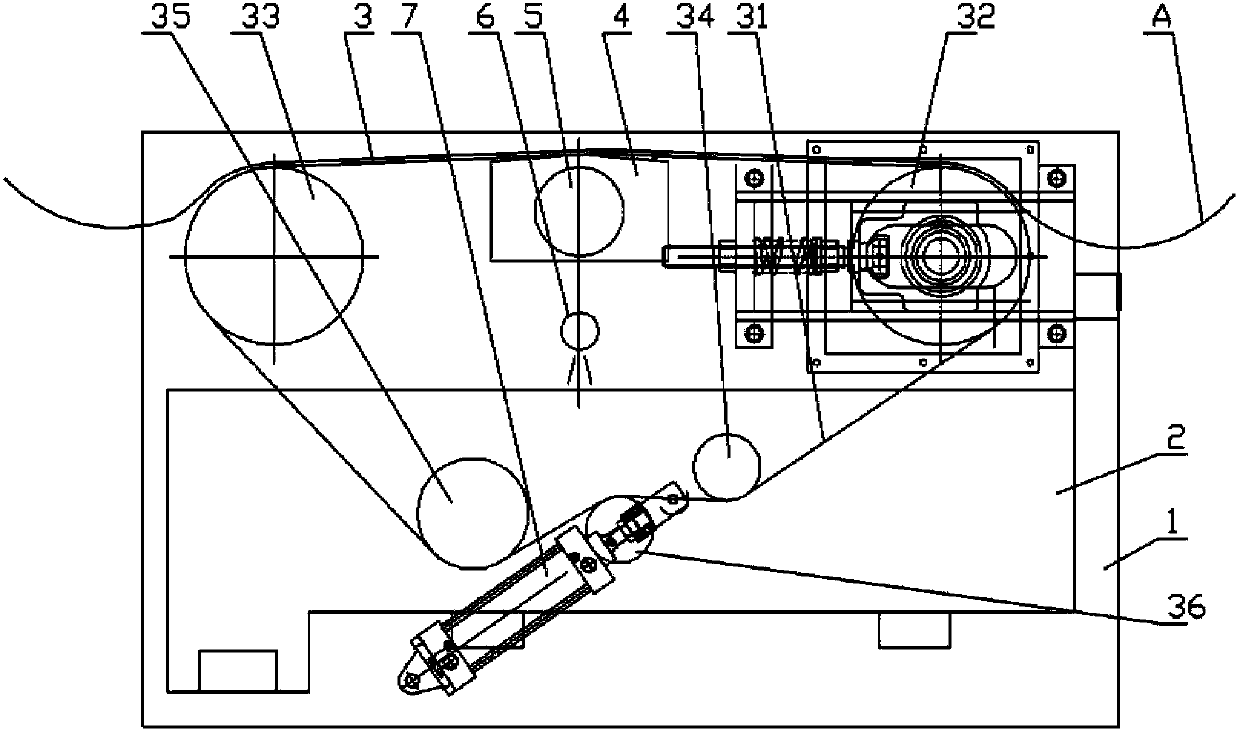

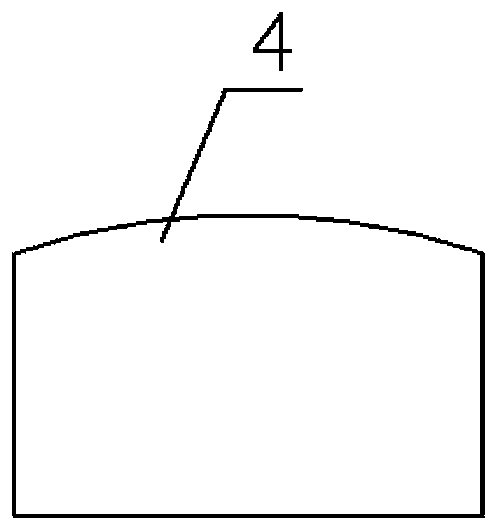

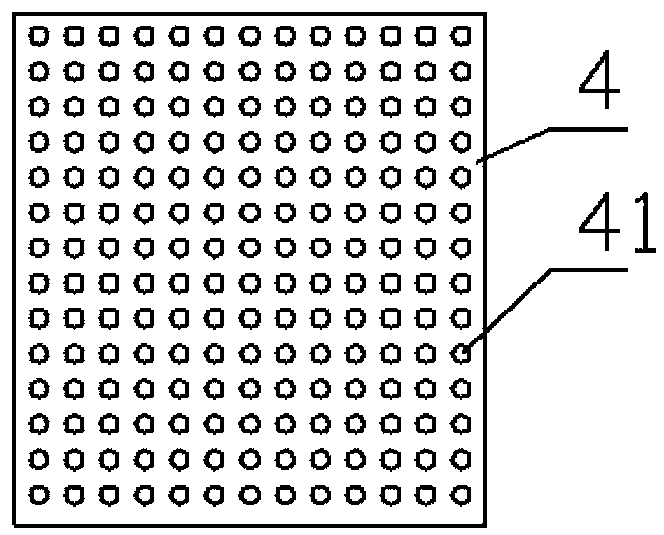

[0015] Example: see Figure 1 to 3 As shown, a wet cloth vacuum dehydrator includes a cabinet 1, a water tank 2 is set in the cabinet 1, a mesh conveyor belt 3 is placed in the cabinet 1, the dehydration box 4 is fixed on the cabinet 1, and the top of the dehydration box 4 is formed with Several dehydration holes 41, the dehydration holes 41 are closely attached to the lower part of the mesh conveyor belt 3, the air inlet pipe of the vacuum machine 5 is connected to the dehydration box 4, and the outlet pipe of the vacuum machine 5 is connected to the gas-water separator 6 for gas-water separation The water outlet of the device 6 faces the pool 2.

[0016] The top of the dehydration tank 4 is arc-shaped.

[0017] The mesh conveyor belt 3 is composed of a mesh belt 31, a driving pulley 32, a driven pulley 33, a first tensioning wheel 34, a second tensioning wheel 35, and a third tensioning wheel 36. The mesh belt 31 is tensioned on the driving pulley 32, the driven pulley 33, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com