Printing and dyeing method for fabric

A cloth and dye technology, applied in the direction of dyeing, spray/jet textile material treatment, liquid/gas/steam removal by suction method, etc., can solve problems such as complex process, high cost, influence on fabric color, etc., achieve simplified process, The effect of uniform particle size and bright fabric color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

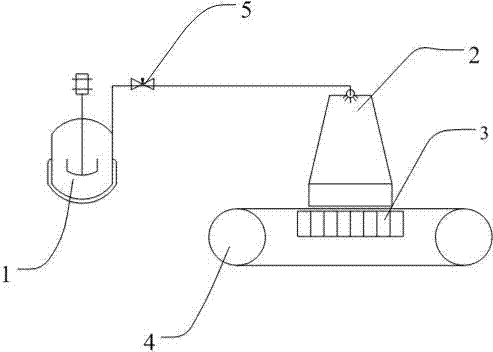

[0012] Put the dye into the pressure tank 1, then inject carbon dioxide into the pressure tank with a high-pressure pump, heat to 40°C after the pressure reaches 7.3MPa, continue to inject carbon dioxide until the pressure is 20MPa, at this time the carbon dioxide is in a supercritical state, stir evenly. The fabric is sent to the dyeing area at a speed of 100 m / min by the mesh conveyor belt through the conveying device 4 (the dyeing area is between the atomization chamber 2 and the vacuum system 3), and the vacuum system 3 is turned on, and the vacuum degree of the vacuum system is -0.04 MPa, open valve 5 at the same time, pump the dye and carbon dioxide in the pressure tank into the atomization chamber, when the atomization chamber sprays out, because the pressure of carbon dioxide drops from 20MPa to below 1 atmospheric pressure instantly, it has a certain effect on the dye in the carbon dioxide medium The blasting effect makes the atomized particles very fine and uniform, a...

Embodiment 2

[0014] The difference from Example 1 is that the temperature in the pressure tank is 50° C. and the pressure is 25 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com