Method for improving softness performance of pigment dyed fabric

A paint dyeing and fabric softening technology, which is applied in the field of improving the softness of paint-dyed fabrics and physical pretreatment to improve the softness of fabrics. It can solve the problems that yarn enhances fabric air permeability, film is easy to fall off, and affects fabric wearability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

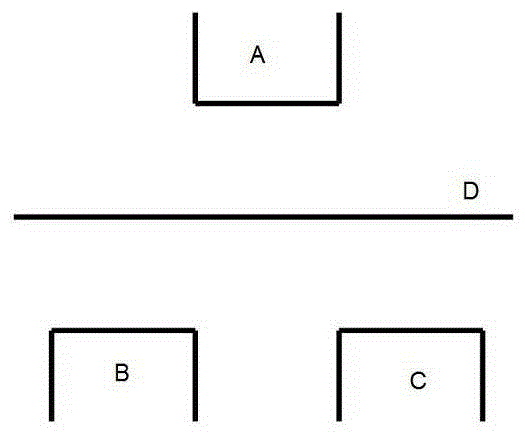

[0013] Example 1 In the whole process of fabric D dyeing with paint, a negative pressure suction wind device is set between fabric D padding dye solution and pre-drying process, after fabric D padding paint, fabric D before drying passes through There is a negative pressure suction device area, the negative pressure of the air outlet of the upper air suction device A, the air outlet of the lower air suction device B and the air outlet of the lower air suction device C are all 1MPa, and the distance between the upper surface of the fabric D and the upper The plane distance of the air outlet of the suction wind device A is 0.1cm, the plane distance of the lower surface of the fabric D is 0.1cm from the air outlet of the lower suction air device B and the air outlet of the lower suction wind device C, and the part of the paint dye solution in the fabric D is made of The upper surface of the fabric D is sucked out through the air outlet of the upper air suction device A, and part o...

Embodiment 2

[0014] Example 2 In the whole process of dyeing the fabric D with paint, a negative pressure suction device is set between the padding of the fabric D and the pre-drying process. After the fabric D is padded with the paint, the undried fabric D passes through There is a negative pressure suction device area, the negative pressure of the air outlet of the upper air suction device A, the air outlet of the lower air suction device B and the air outlet of the lower air suction device C are all 5MPa, and the distance between the upper surface of the fabric D and the upper The plane distance of the air outlet of the suction wind device A is 0.3cm, the plane distance of the lower surface of the fabric D is 0.3cm from the suction air outlet of the lower suction wind device B and the air suction port of the lower suction wind device C, and the part of the paint dye solution in the fabric D is made of The upper surface of the fabric D is sucked out through the air outlet of the upper air...

Embodiment 3

[0015] Example 3 In the whole process of fabric D dyeing with paint, a negative pressure suction wind device is set between fabric D padding and pre-drying process, after fabric D padding paint, fabric D before drying passes through There is a negative pressure suction device area, the negative pressure of the air outlet of the upper air suction device A, the air outlet of the lower air suction device B and the air outlet of the lower air suction device C are all 3MPa, and the distance between the upper surface of the fabric D and the upper The plane distance of the air outlet of the suction wind device A is 0.2cm, the plane distance of the lower surface of the fabric D is 0.2cm from the suction air outlet of the lower suction air device B and the air suction port of the lower suction wind device C, and the part of the paint dye solution in the fabric D is made of The upper surface of the fabric D is sucked out through the air outlet of the upper air suction device A, and part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com