Pressing device for digital textile printing machine

A technology of a digital printing machine and a pressing device, which is applied in the directions of printing devices, printing, typewriters, etc., can solve the problems of inability to iron fabrics, incapable of dust removal and cooling, inability to press fabrics, etc., so as to improve quality and facilitate popularization and utilization. Value, good for flattening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

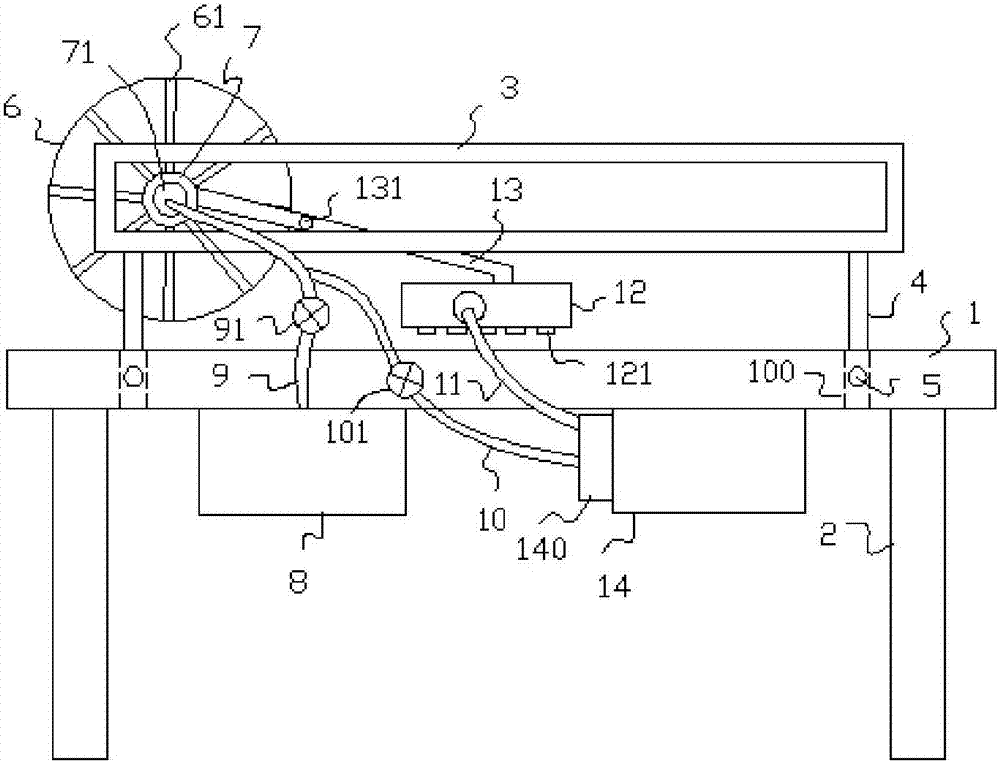

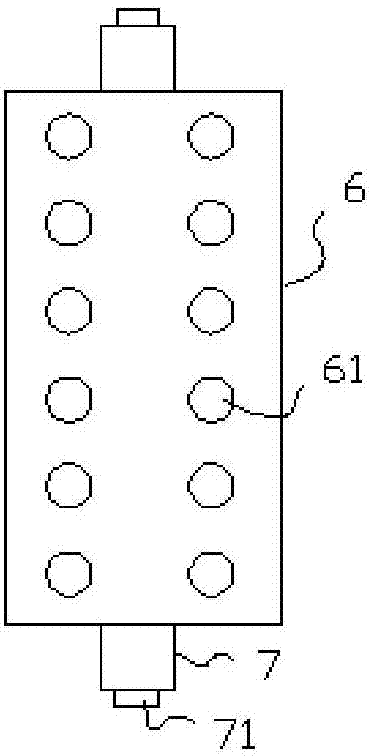

[0022] like figure 1 , figure 2 As shown, the press device for this kind of digital printing machine has a structure including a workbench 1, the bottom of the workbench 1 is provided with a leg 2, and the workbench 1 is provided with a pressure roller 6, and the pressure roller 6 The two sides are rotatably connected with the horizontally arranged guide rails 3 through the rotating shaft 7 respectively, and the inner rotating shaft (not shown in the figure) is connected with the driving device (not shown in the figure) through a chain (not shown in the figure). The pressure roller 6 is provided with a hollow cavity (not shown in the figure) inside, and several through holes 61 are provided between the side of the cavity and the outer surface of the pressure roller 6, and the rotating shaft 7 on the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com