Method for digital textile printing in wet state

A digital printing, wet state technology, applied in textiles, papermaking, dyeing and other directions, can solve the problems of weft bias, easy yellowing pretreatment liquid, energy, waste, etc. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of the pretreatment solution: first add 2% baking soda, 10% urea, 1% anti-staining salt S, and 0.3% sodium metasilicate into water and stir to dissolve to obtain a uniform mixed solution; continue Stir the above mixed solution, slowly add 3% sodium alginate, continue to stir for 1.5 hours, and let it stand for 2 hours to obtain the pretreatment working solution. The viscosity of the pretreatment working solution is 6000mPa·s, and the pH is 9.

[0031] (2) Squeegee treatment: Use a 100-mesh screen to squeegee the dry textiles with the pretreatment working liquid. The squeegee pressure is 5mV, and the squeegee speed is 20mm / s, and the pretreatment liquid is evenly sent to the screen. , evenly squeegee the pretreatment liquid on the textile, and the liquid carrying rate of the textile is 40.5%;

[0032] (3) Digitally print, dry, steam, and wash the wet textiles after pretreatment.

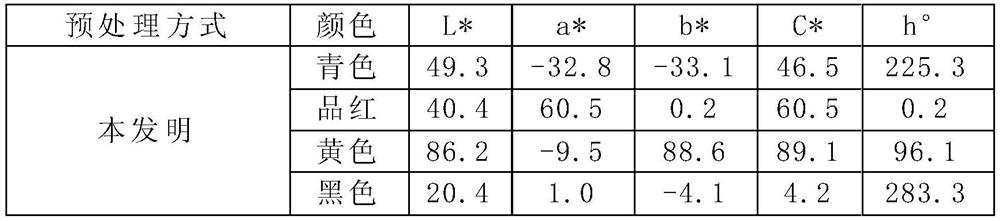

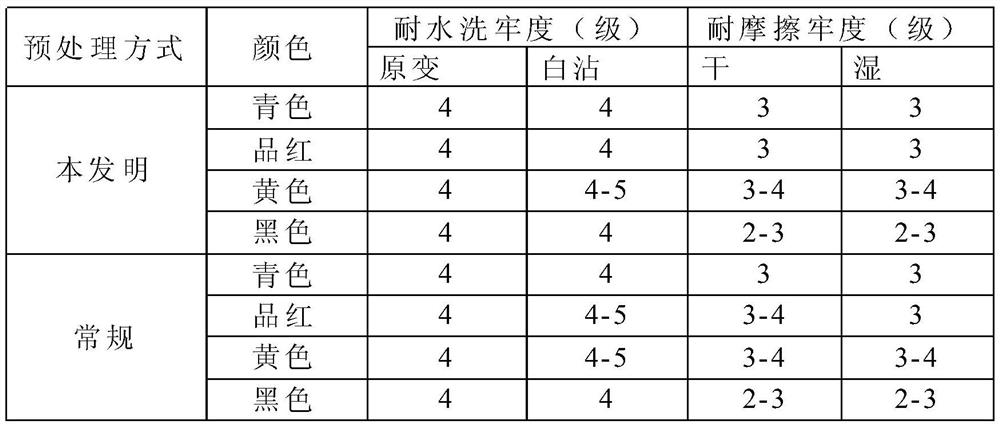

[0033] Use Datacolor 650 color measuring instrument to test and character...

Embodiment 2

[0042] (1) Preparation of pretreatment solution: first add 2.5% baking soda, 15% urea, 1.5% anti-staining salt S, and 0.5% sodium metasilicate into water and stir to dissolve to obtain a uniform mixed solution; continue Stir the above mixed solution, slowly add 2% methyl hydroxyethyl cellulose, continue to stir for 0.5 h, and let stand for 2 h to obtain the pretreatment working solution. The viscosity of the pretreatment working solution is 500mPa·s, and the pH is 8.

[0043] (2) Squeegee treatment: Squeeze the dry textiles with the pretreatment working liquid using a stencil with a mesh number of 80. The squeegee pressure is 5mV, and the squeegee speed is 22mm / s, and the pretreatment liquid is evenly sent to the stencil. , evenly squeegee the pretreatment liquid on the textile, and the liquid carrying rate of the textile is 35.5%;

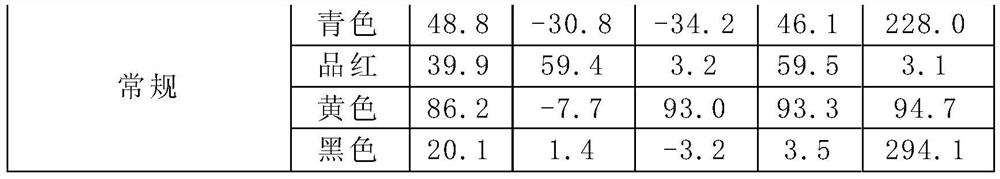

[0044] (3) Digitally print the pretreated wet textiles directly, dry, steam, and wash, and compare the printing with conventional pretreated fab...

Embodiment 3

[0053] (1) Preparation of pretreatment solution: first add 4% baking soda, 20% urea, 2% anti-staining salt S, and 1% sodium metasilicate into water and stir to dissolve to obtain a uniform mixed solution; continue Stir the above mixed solution, slowly add 5% modified starch, continue to stir for 0.5h, and let stand for 2h to obtain the pretreatment working solution. The viscosity of the pretreatment working solution is 10000mPa·s, and the pH is 10.

[0054] (2) Squeegee treatment: Squeeze the dry textiles with the pretreatment working liquid using a screen with a mesh number of 90. The squeegee pressure is 1mV, and the squeegee speed is 50mm / s, and the pretreatment liquid is evenly sent to the screen. , evenly squeegee the pretreatment liquid on the textile, and the liquid carrying rate of the textile is 30%;

[0055] (3) Digitally print, dry, steam, and wash the wet textiles after pretreatment.

[0056] Use Datacolor 650 color measuring instrument to test and characterize t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com