Method and apparatus for digital textile printing

A textile and digital control technology, which is applied in the direction of textiles and papermaking, textile material treatment, textile material local treatment, etc., can solve the problems of polluted wastewater, etc., and achieve the effects of reducing wastewater discharge, reducing demand, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

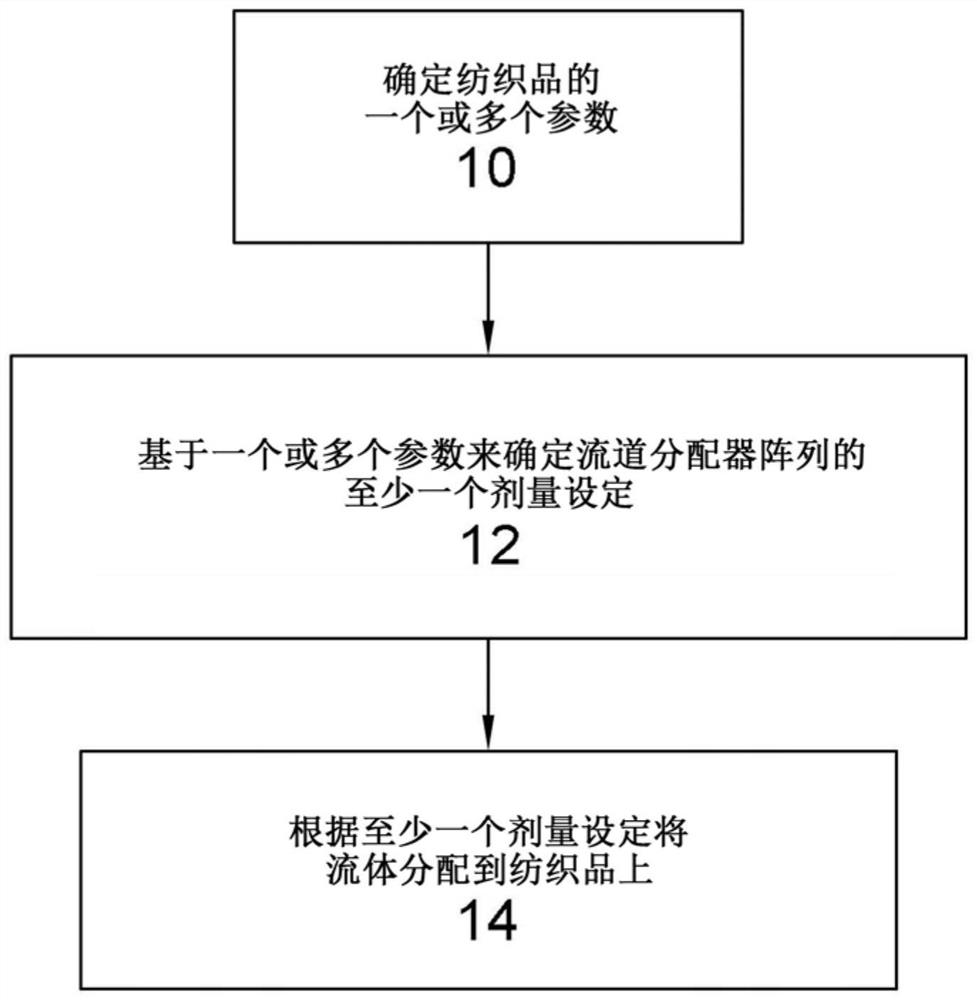

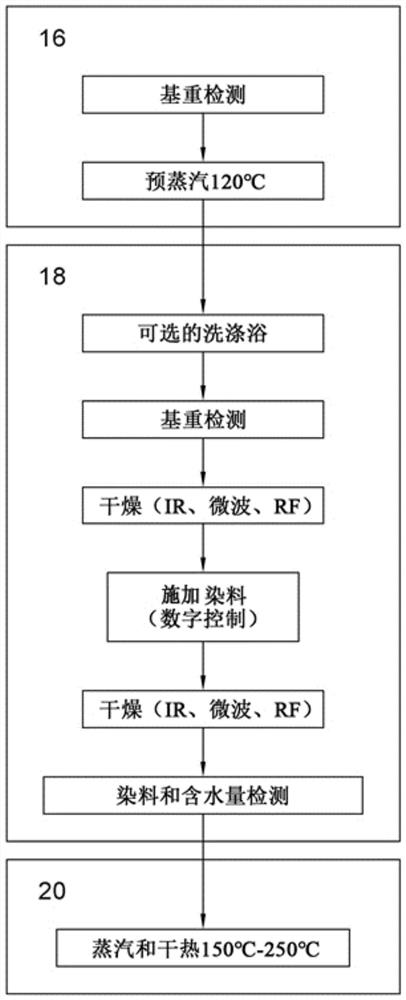

[0103] refer to figure 1 , an exemplary method according to the present invention includes determining one or more parameters of a textile 10 conveyed on a production line. This determination may be done via user input, automatic input, or via digital sensing via one or more sensors on the production line equipment. Exemplary parameters that can be entered or sensed are: Typically at 50gm -2 up to 500gm -2 The basis weight of the textile, the fiber density / diameter of the textile, and the weave type of the textile.

[0104] The illustrated method also includes the step of determining at least one dose setting for the array of flow channel distributors based on the one or more parameters 12 determined in the first step. This determination is performed by a processor 50 configured to control the array of flow channel distributors. In some embodiments, the array of flow channel distributors may comprise a portion of a printhead configured to dispense dye.

[0105] The use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com