Method for preparing electronic grade phosphoric acid through liquid membrane crystallization

An electronic-grade phosphoric acid and crystallization technology, applied in the direction of phosphoric acid, phosphorus oxyacid, etc., can solve the problems of low operating temperature, high production cost, and long operating time, and achieve high impurity removal rate, short production time, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

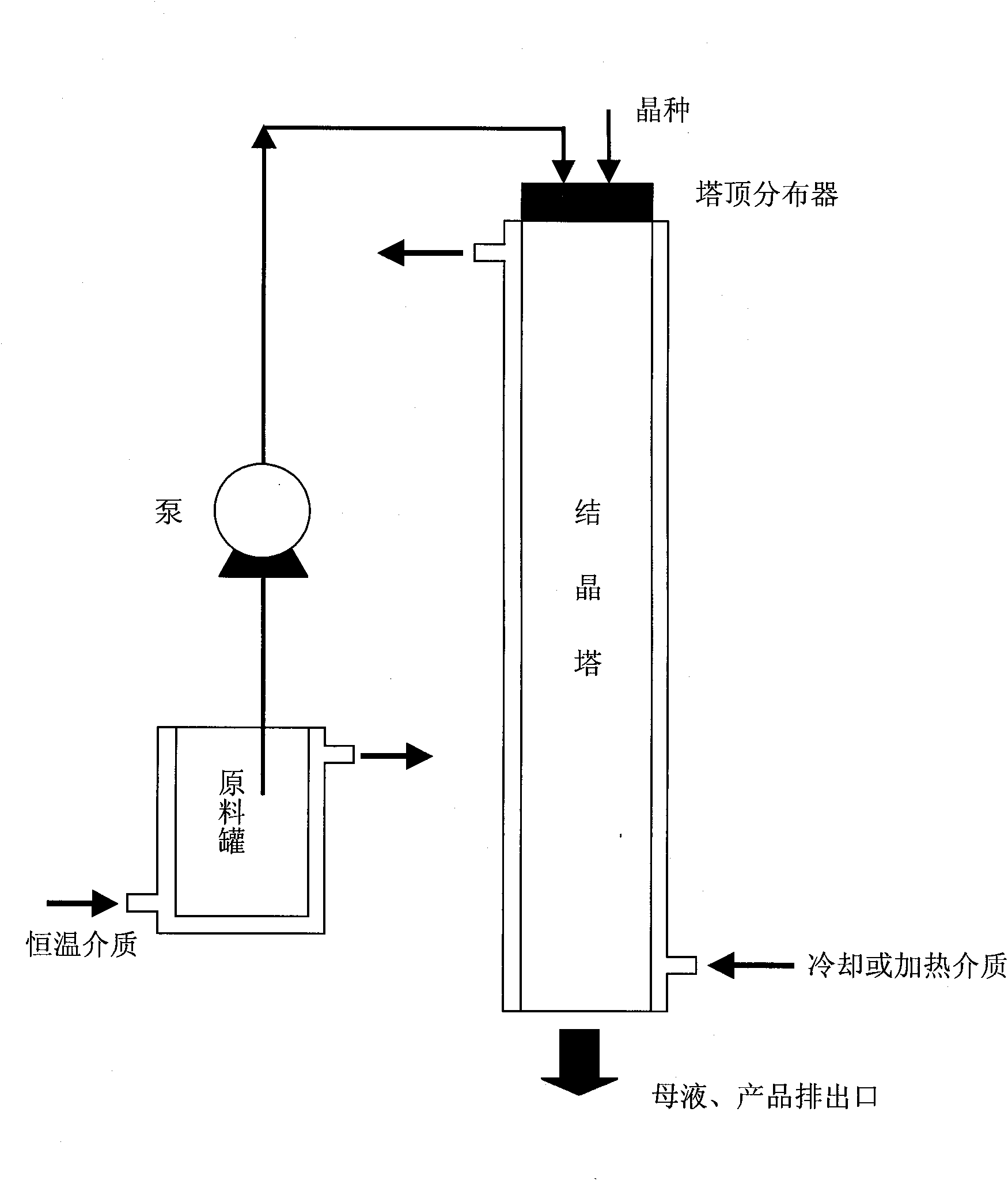

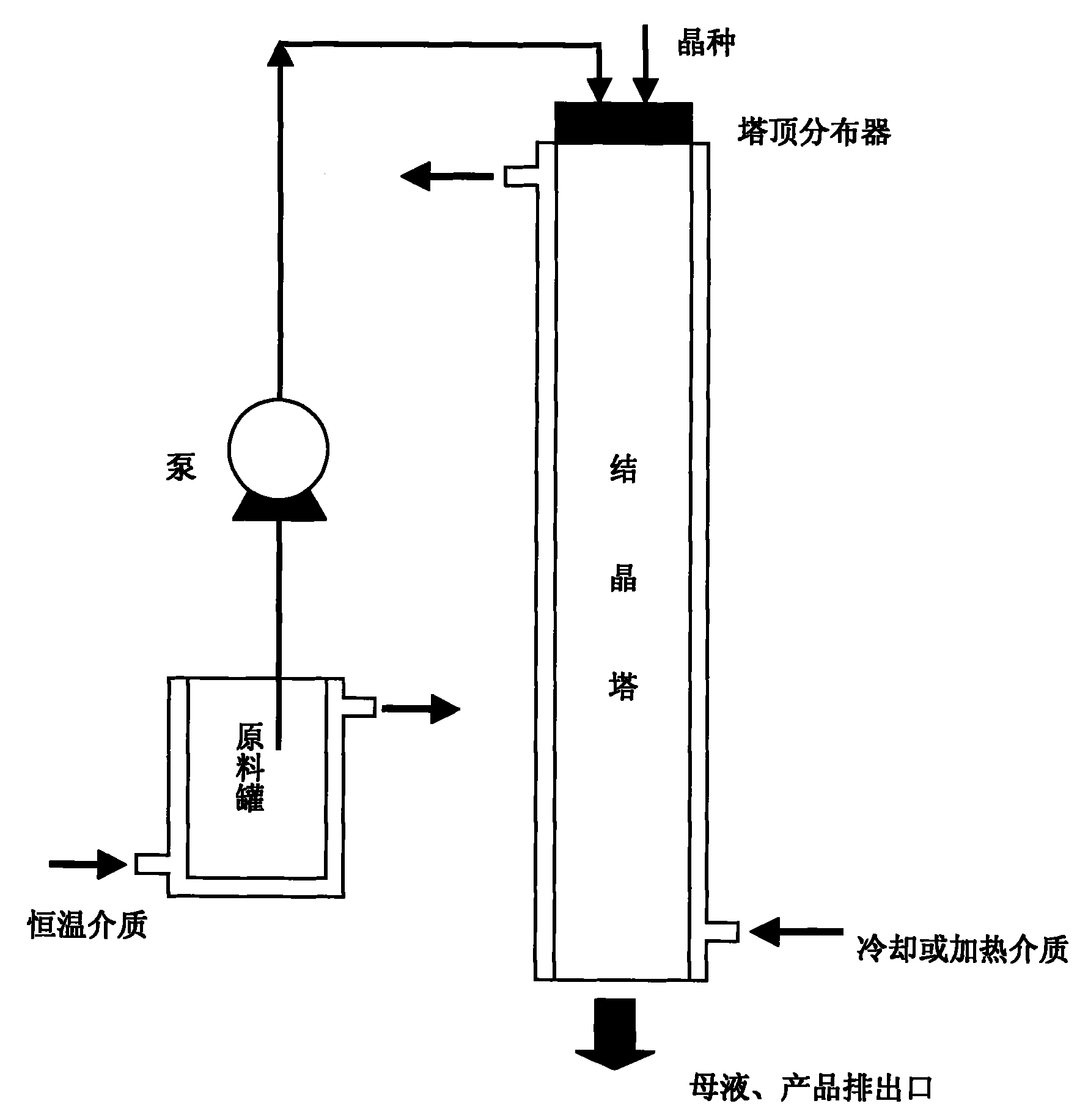

[0029] use figure 1 For the liquid film crystallization device shown, take 2000 g of 85% raw material phosphoric acid (the impurity content is shown in Table 1), place it in a jacketed glass container, and control the rate of feeding liquid by a peristaltic pump. Use a tower crystallizer to perform a liquid film crystallization operation, slowly pour the pre-prepared seed crystals on the wall of the crystallization tower at 13°C, and feed the raw material phosphoric acid liquid into the crystallization tower from the top of the tower, so that the feed liquid is in the form of a film. The wall surface is lowered, and at the same time, the temperature of the crystallization tower wall is lowered to 5°C. The feed liquid crystallizes on the crystallization tower wall to form a crystal film, and the uncrystallized liquid flows out from the bottom of the crystallization tower. When the thickness of the crystal film layer reaches 1 / 3 of the diameter of the tower, stop feeding the raw...

Embodiment 2、3、4

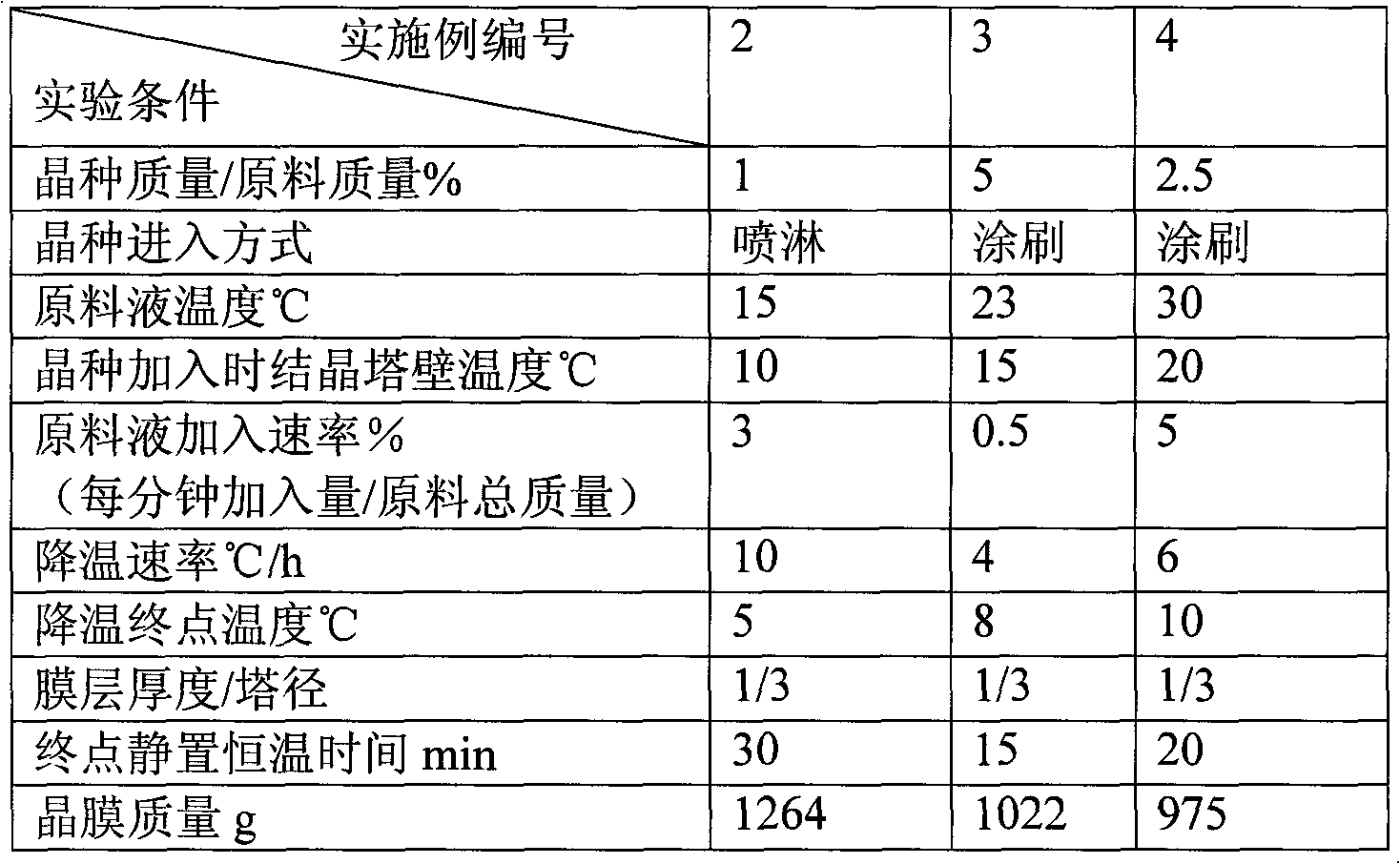

[0035] use figure 1 For the liquid film crystallization device shown, take 2000 g of 85% food-grade phosphoric acid (the content of impurities is shown in Table 2), and place it in a glass container with a jacket. rate. A tower crystallizer with an aspect ratio of 20:1 was used, and the cooling stage operation in the liquid film crystallization was carried out according to the operating conditions shown in Table 3. Sprinkle the pre-prepared crystal seeds on the wall of the crystallization tower, add the raw material phosphoric acid, and reduce the temperature of the crystallization tower wall at the same time, so that the material liquid descends in the form of a film on the wall, crystallizes to form a crystal film, and the uncrystallized liquid flows out from the bottom of the crystallization tower . After the raw materials are added and the end point of cooling is reached, it is left to stand at a constant temperature to fully discharge the uncrystallized feed liquid.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com