Corn starch adhesive for building and preparation method thereof

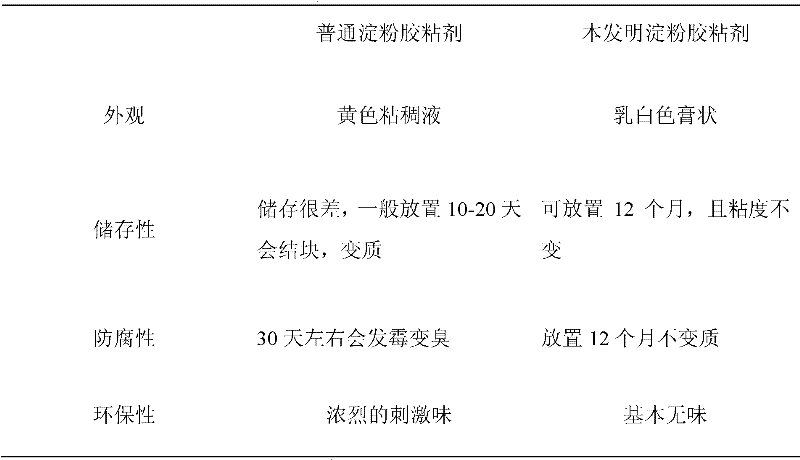

A technology of corn starch and adhesives, applied in the direction of starch-derived adhesives, adhesive types, etc., can solve the problems of poor water resistance and stability, dark color of starch adhesives, etc., to improve bonding ability, increase product viscosity, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The cornstarch purchased in the market is used as raw material, and tap water is used as water source.

[0022] Put 30g of cornstarch and 70g of water into a three-neck round bottom flask, stir evenly, then heat up to 60°C, add 0.8ml of 30% hydrogen peroxide and 4ml of 0.1% copper sulfate, and oxidize for 1.5 hours.

[0023] After cooling the above oxidized solution, 10% sodium hydroxide solution was added to adjust the pH value to 9. Then add eg 2 g of acetic anhydride while maintaining the pH at 9 with 10% sodium hydroxide solution. The addition was completed in about 20 minutes, and then reacted for 40 minutes.

[0024] Add the above solution to sodium benzoate and adjust the pH value to 5 with 10% sodium bisulfite solution, add water to make the total amount reach 200g, and then gelatinize at 70°C to obtain a starch adhesive.

Embodiment 2

[0026] The cornstarch purchased in the market is used as raw material, and tap water is used as water source.

[0027] Put 30g of cornstarch and 70g of water into a three-neck round bottom flask, stir evenly, then heat up to 60°C, add 0.8ml of 30% hydrogen peroxide and 4ml of 0.1% copper sulfate, and oxidize for 4 hours.

[0028] After cooling the above oxidized solution, 10% sodium hydroxide solution was added to adjust the pH value to 9. Then 2 g of acetic anhydride were added while maintaining the pH at 9 with 10% sodium hydroxide solution. The addition was completed in about 20 minutes, and then reacted for 40 minutes.

[0029] Add the above solution to sodium benzoate and adjust the pH value to 5 with 10% sodium bisulfite solution, add water to make the total amount reach 200g, and then gelatinize at 70°C to obtain a starch adhesive.

Embodiment 3

[0031] The cornstarch purchased in the market is used as raw material, and tap water is used as water source.

[0032] Put 30g of cornstarch and 70g of water into a three-neck round bottom flask, stir evenly, then heat up to 60°C, add 0.8ml of 30% hydrogen peroxide and 4ml of 0.1% copper sulfate, and oxidize for 1.5 hours.

[0033] After cooling the above oxidized solution, 10% sodium hydroxide solution was added to adjust the pH value to 9. Then 1.5 g of acetic anhydride were added while maintaining the pH at 9 with 10% sodium hydroxide solution. The addition was completed in about 20 minutes, and then reacted for 40 minutes.

[0034] Add the above solution to sodium benzoate and adjust the pH value to 5 with 10% sodium bisulfite solution, add water to make the total amount reach 200g, and then gelatinize at 70°C to obtain a starch adhesive.

PUM

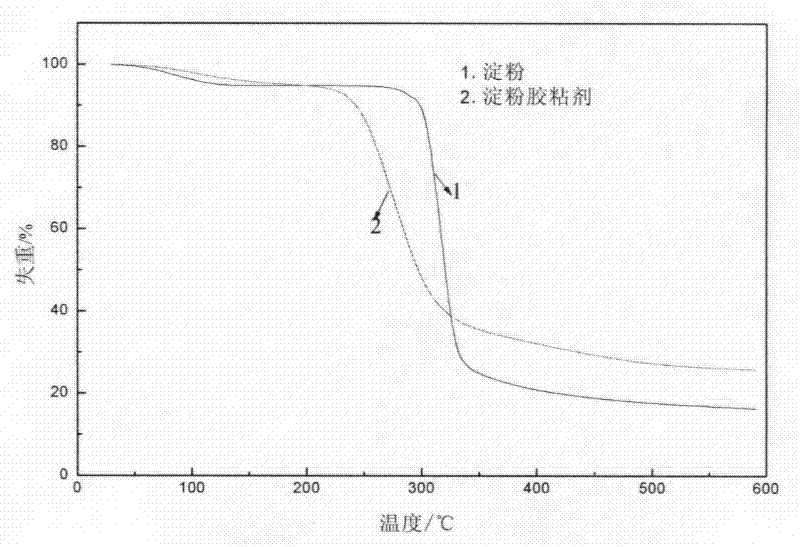

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com