Vitamin C sustained-release pellets and method for preparing same

A technology of slow-release pellets and vitamins, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, block delivery, etc. It can solve the problems of unfavorable capsule filling, long time consumption, poor patient compliance, etc., and achieve unit volume The effect of large drug loading, simple product prescription, and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

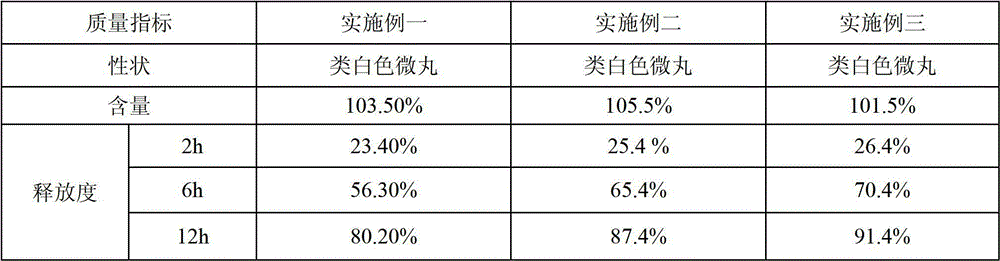

Examples

preparation example Construction

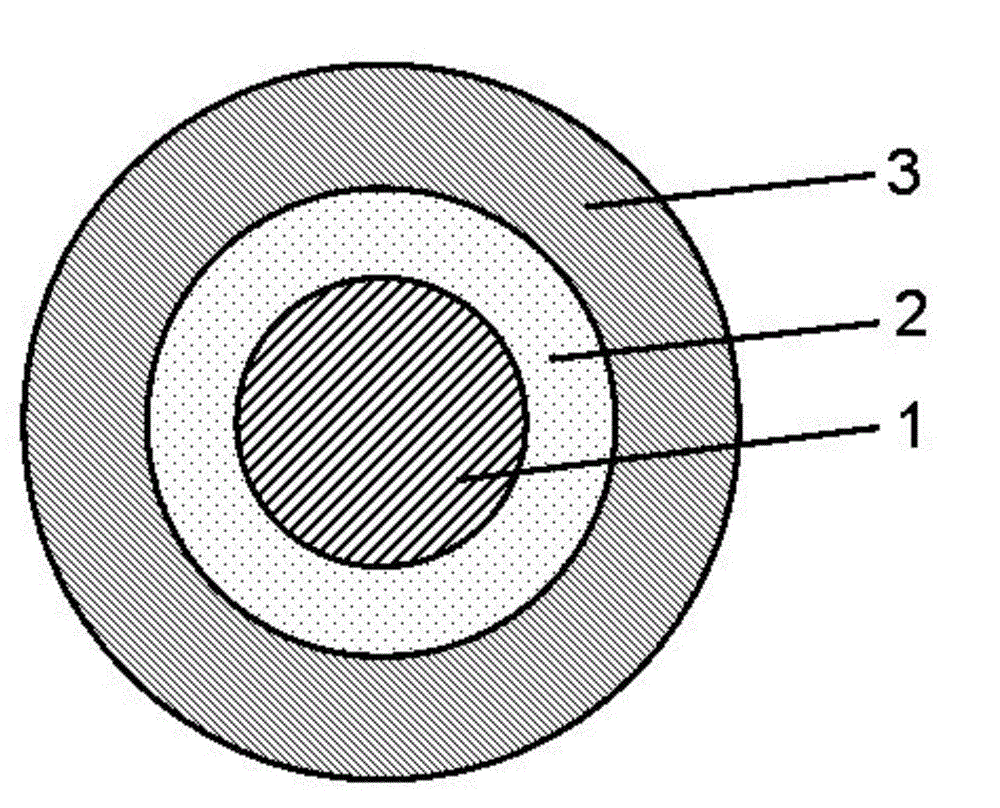

[0019]A vitamin C sustained-release pellet, consisting of a vitamin C vegetarian pill and a slow-release coating layer 3, the vitamin C vegetarian pill is composed of a mother core 1 and a laminated layer 2, and the vitamin C vegetarian pill is composed of a vitamin C and vitamin C vegetarian pill auxiliary materials, or the vitamin C vegetarian pills are composed of vitamin C, and the slow-release coating layer 3 is composed of slow-release coating materials and slow-release coating layer auxiliary materials, or the slow-release coating layer Release coating layer 3 is made up of sustained-release coating material, and described vitamin C vegetarian pellet supplementary material is selected from one or both of fillers, binders, and described sustained-release coating layer supplementary material is selected from plasticizing One or both of anti-adhesive agent and anti-adhesive agent; the weight percentage content of vitamin C in the mother core 1 and laminated layer 2 is the s...

Embodiment 1

[0028] Vitamin C Sustained Release Pellets Prescription

[0029] Vitamin C pill prescription:

[0030] Vitamin C 1000g

[0031] Hydroxypropyl Methyl Cellulose 5g

[0032] ER Coating 3 Prescription:

[0033] Su Lisi (solid content) 42g

[0034] Preparation Process:

[0035] (1) Crush and sieve vitamin C.

[0036] (2) Prepare the prescribed amount of hydroxypropyl methylcellulose with water to make a 3% aqueous solution of hydroxypropyl methylcellulose as a binding solution.

[0037] (3) Weigh vitamin C according to the prescription amount as a vegetarian pill powder

[0038] (4) Take part of the above-mentioned vegetarian pill powder and binding liquid, and use a wet granulator to prepare vitamin C wet granules. The particle size is guaranteed to be about 40 mesh, and it is dried to ensure that the moisture content after drying is less than 2.0%. 1. Wet granulation process parameters: Stirring speed: 45HZ, granulation speed 45HZ, wet mixing time 1-3 minutes.

[0039]...

Embodiment 2

[0044] Vitamin C Sustained Release Pellets Prescription

[0045] Vitamin C pill prescription:

[0046] Vitamin C 800g

[0047] Microcrystalline Cellulose 200g

[0048] Hydroxypropyl methylcellulose (10cp) 16.5g

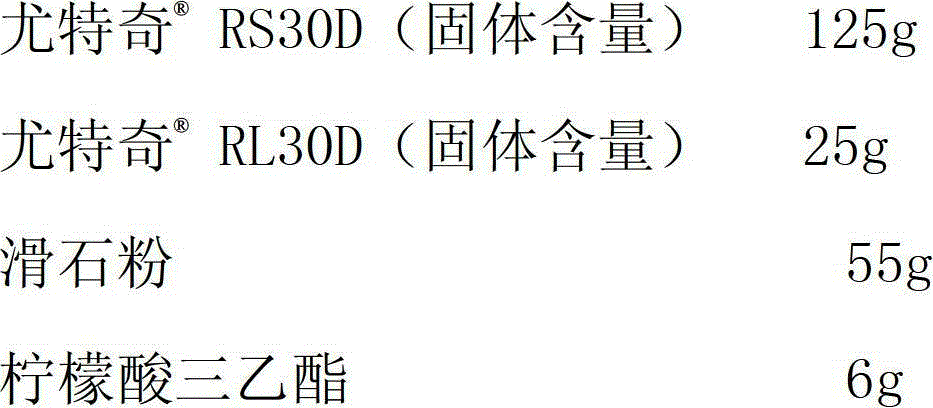

[0049] ER Coating 3 Prescription:

[0050] Ethyl cellulose (10cp) 80g

[0051] Triethyl citrate 8g

[0052] Preparation Process:

[0053] (1) Crush and sieve vitamin C.

[0054] (2) Prepare the prescribed amount of hydroxypropyl methylcellulose with water to make a 3% aqueous solution of hydroxypropyl methylcellulose as a binding solution.

[0055] (3) Weigh vitamin C and microcrystalline cellulose according to the prescription amount, mix them evenly, and use them as vegetarian pill powder.

[0056] (4) Take part of the above-mentioned vegetarian pill powder and binding liquid, and use a wet granulator to prepare vitamin C wet granules, with a particle size of about 60-40 mesh, and dry them to ensure that the moisture after drying is less than 2.0%. core 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com