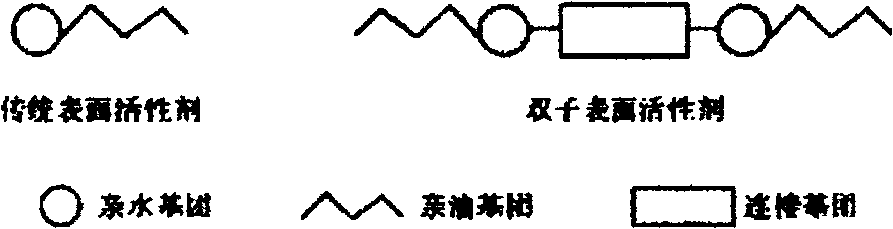

Synthetic method of gemini quaternary ammonium salt surfactant and application as drag reduction agent

A technology of surfactants and quaternary ammonium salts, applied in chemical instruments and methods, transportation and packaging, descaling and water softening, etc., can solve problems such as narrow applicable temperature range, strong corrosion, and large irritation, and achieve biological High safety, good drag reduction performance, overcoming strong corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

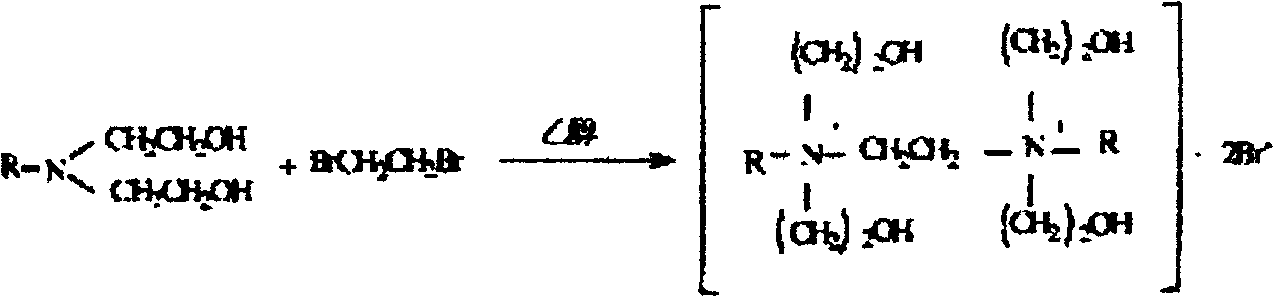

[0036] Synthesis of Gemini Quaternary Ammonium Surfactant (Gemini 1) Using Coco Dimethyl Tertiary Amine and Dibromoethane as Raw Materials

[0037] In a 1000mL four-neck reaction flask equipped with a mechanical stirrer, a thermometer, a dropping funnel, and a reflux condenser, add 300mL absolute ethanol and 227g (1.0mol) of coco dimethyl tertiary amine, stir and dissolve, and heat to reflux temperature, 75.2g (0.4mol) of dibromoethane reagent was added dropwise within 6 hours, and the reflux was maintained for 4 hours after the addition, and the progress of the quaternary amination reaction was tracked by measuring the residual tertiary amine content in the reaction solution. When the conversion rate of tertiary amine reaches more than 75% and no longer increases, the quaternary amination reaction is stopped, and 200 mL of ethanol solvent is recovered by vacuum evaporation to obtain a white viscous substance. Dissolve the distilled product with 500 mL of deionized water, then...

Embodiment 2

[0039] Synthesis of Gemini Quaternary Ammonium Surfactant (Gemini 2) Using Coconut Dihydroxyethylamine as Raw Material

[0040] In a 1000mL four-neck reaction flask equipped with a mechanical stirrer, a thermometer, a dropping funnel, and a reflux condenser, add 300mL of absolute ethanol and 287g (1.0mol) of coco-dihydroxyethyl tertiary amine, stir to dissolve, and heat to At the reflux temperature, 75.2 g (0.4 mol) of dibromoethane reagent was added dropwise within 6 hours. After the addition, the reflux was continued for 4 hours. The quaternary amination reaction progress was tracked by measuring the residual tertiary amine content in the reaction solution. When the conversion rate of the tertiary amine reaches more than 75% and no longer increases, the reaction is stopped, and 200 mL of ethanol solvent is recovered by vacuum evaporation to obtain a white viscous substance. Dissolve the distilled product with 500 mL of deionized water, then transfer it into a reaction flask,...

Embodiment 3

[0042] Synthesis of Gemini Quaternary Ammonium Surfactant (Gemini 3) Using Coco-Dihydroxyethylamine and Epichlorohydrin as Raw Materials

[0043] In a 1000mL four-necked reaction flask equipped with a mechanical stirrer, a thermometer, a dropping funnel and a reflux condenser, add 300mL of absolute ethanol, add 287g (1.0mol) of coco-dihydroxyethyl tertiary amine and 48.7g of 30% hydrochloric acid. g (0.4mol), stir and dissolve, heat to reflux temperature, add epichlorohydrin reagent 37.0g (0.4mol) dropwise within 6 hours, keep refluxing for 4 hours after adding, measure the residual tertiary amine content in the reaction solution to track the progress of the quaternary amination reaction. When the conversion rate of the tertiary amine reaches more than 75% and no longer increases, the reaction is stopped, and 200 mL of ethanol solvent is recovered by vacuum evaporation to obtain a white viscous substance. Dissolve the distillation product with 300 mL of deionized water, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com